Apparatus for treating molten atomic reactor fuel rod using vertical cavity

A nuclear reactor, vertical cavity technology, used in reactors, nuclear engineering, nuclear power generation, etc., can solve problems such as the allowable cooling capacity limit, sudden steam generation, etc., to reduce energy, prevent radioactive pollution, and prevent radiation from leaking into the surrounding environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, exemplary embodiments of the present invention will be described with reference to the accompanying drawings so as to be easily implemented by those skilled in the art.

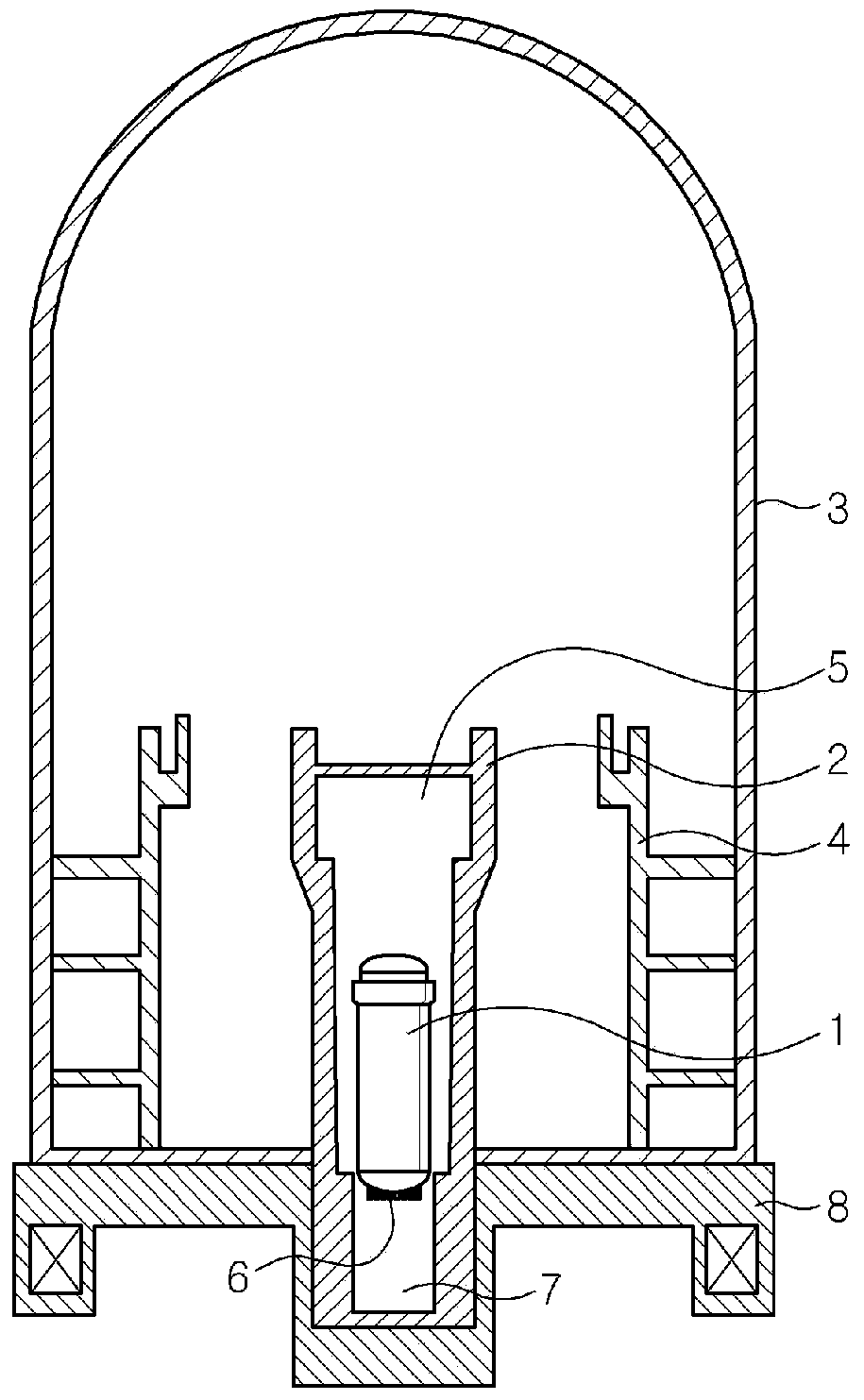

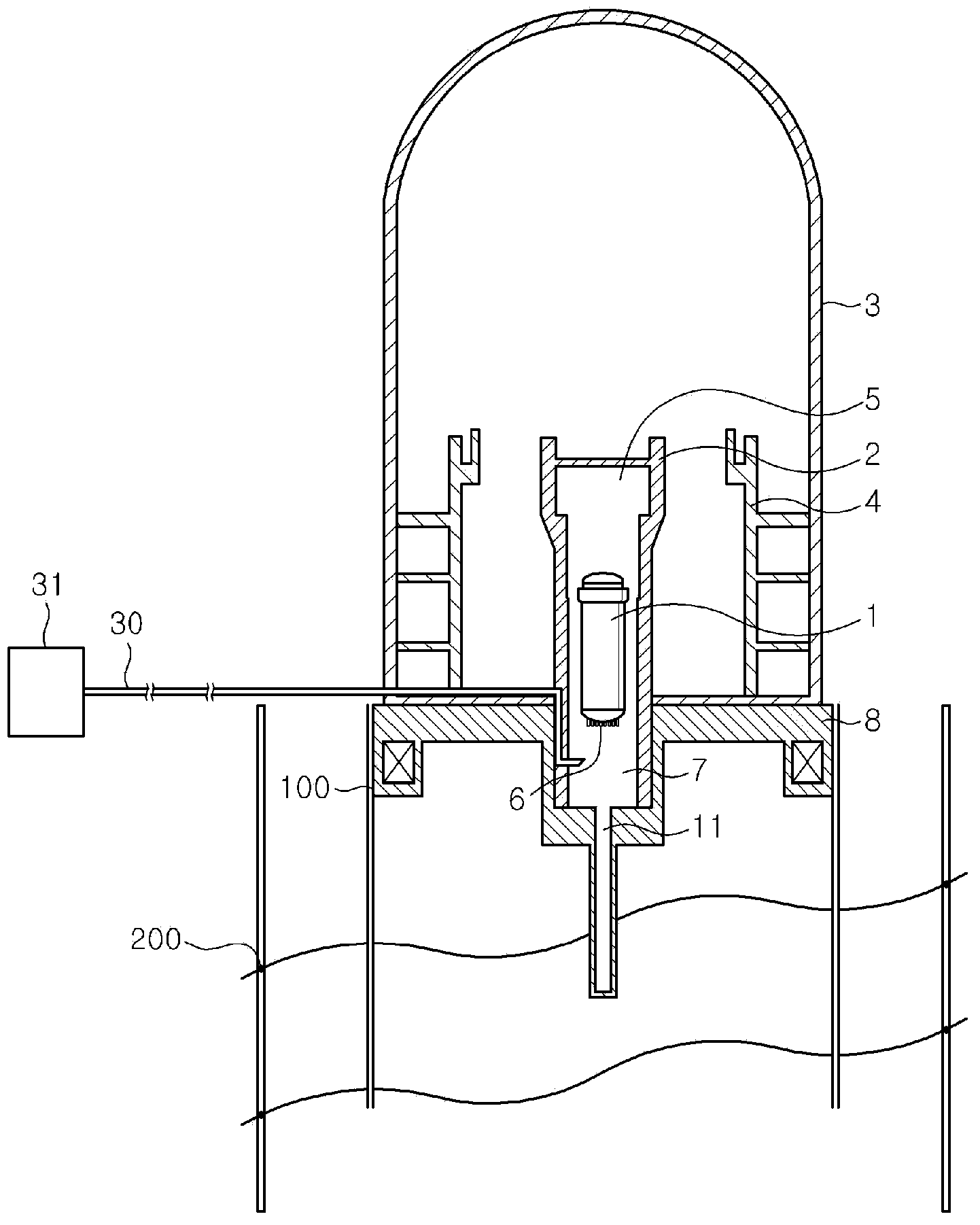

[0024] figure 2 The overall structure of an apparatus for processing molten fuel rods of a nuclear reactor according to an embodiment of the present invention is shown. Such as figure 2 As shown in , in the apparatus of the present invention, an enclosed building 3 is formed around the reactor containment vessel 1 , and the primary barrier 1 and the secondary barrier 4 are installed in the enclosed building 3 . The main barrier 2 is supported by a substrate 8 .

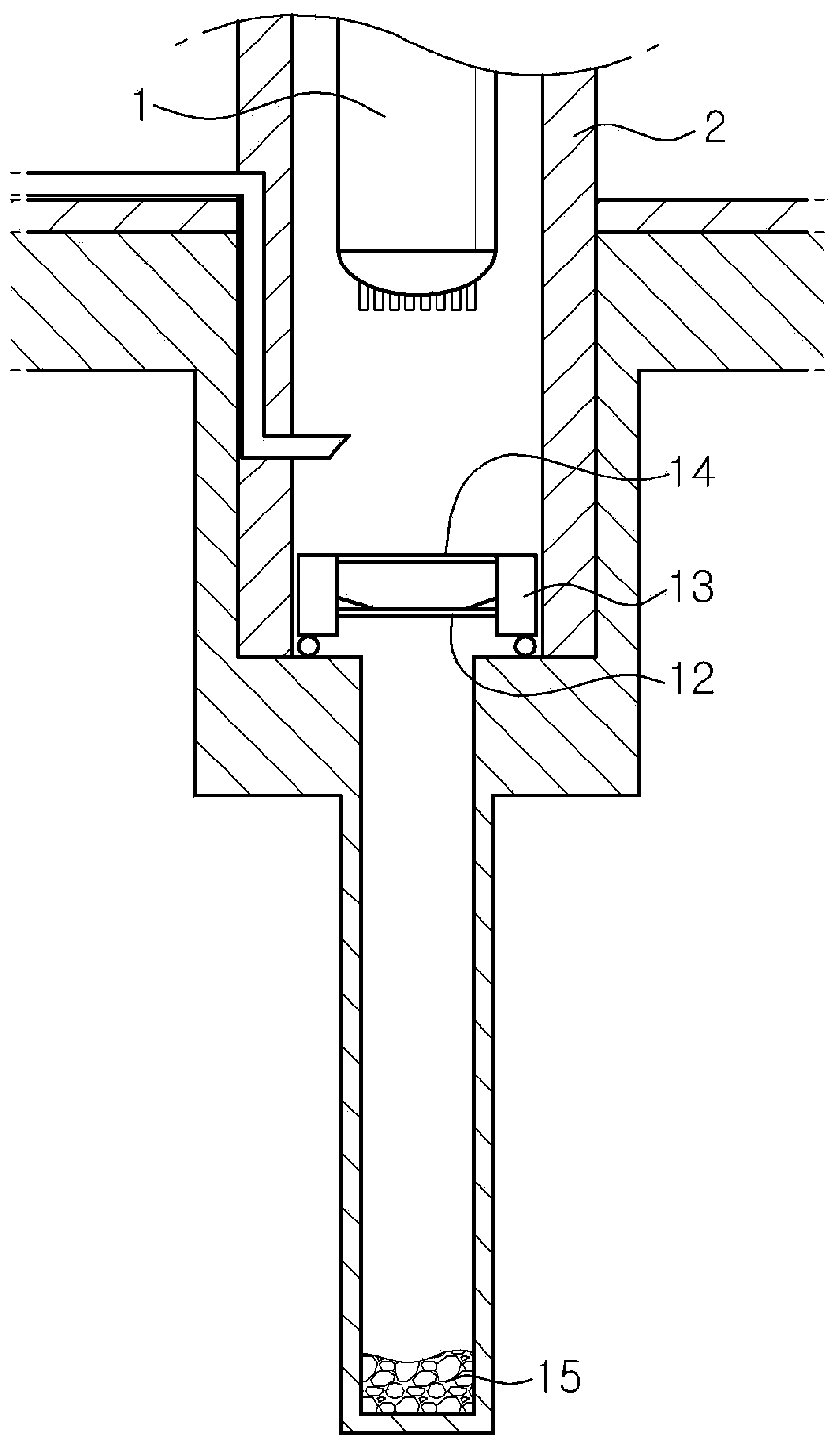

[0025] An opening is formed at the bottom of the main spacer 2 , and a long vertical cavity 11 for embedding molten fuel rods is formed in the base plate 8 supporting the main spacer 2 .

[0026] Because the vertical cavity 11 is formed up to the underground bedrock, the fuel rods 6 fall from the reactor containment vessel 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com