Pressing of transformer windings during active part drying

A technology for transformers and transformer cores, applied in transformer/inductor parts, transformer handling devices, magnetic core manufacturing, etc., can solve problems such as complexity, time-consuming, and loss of winding stabilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

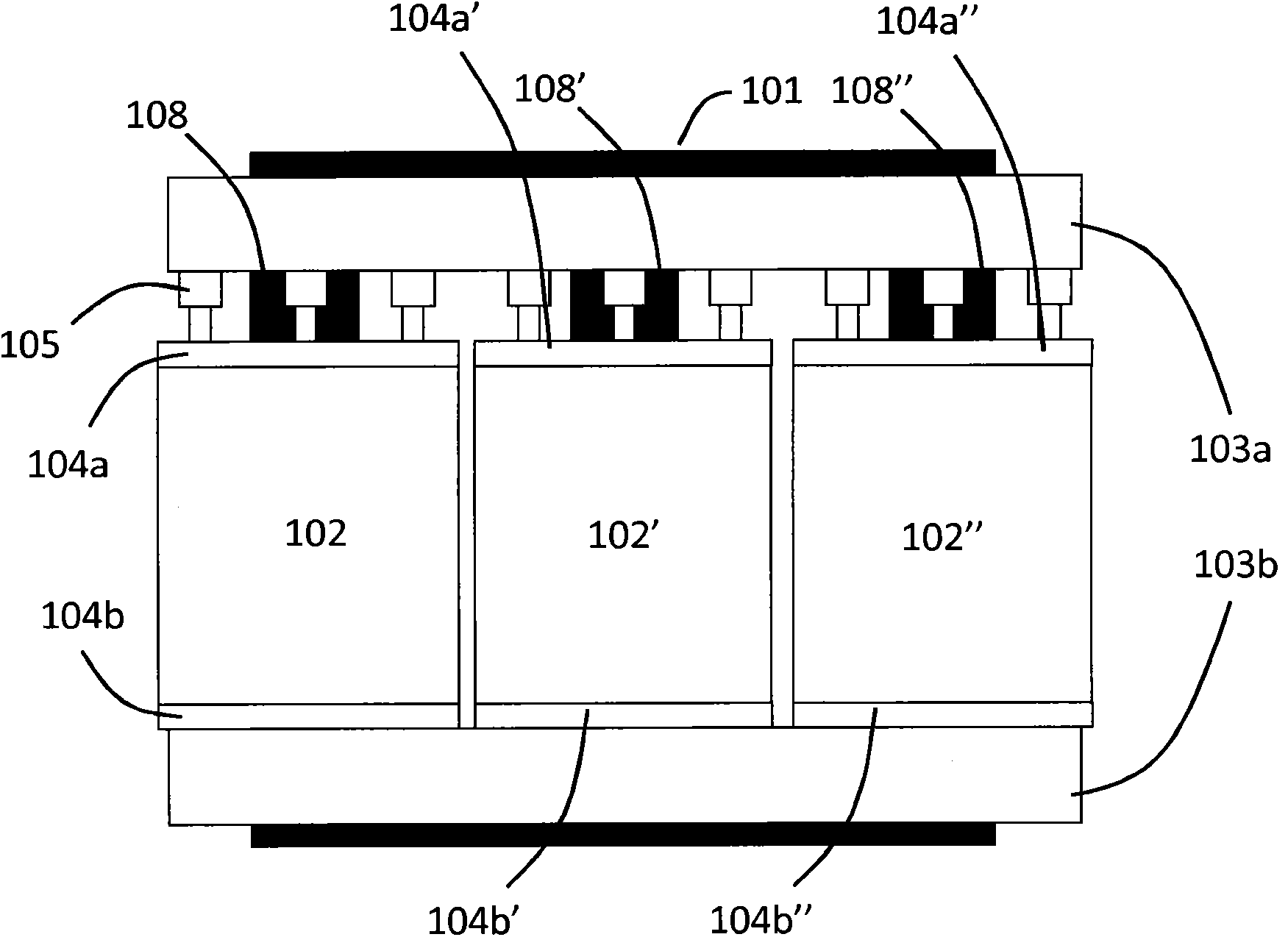

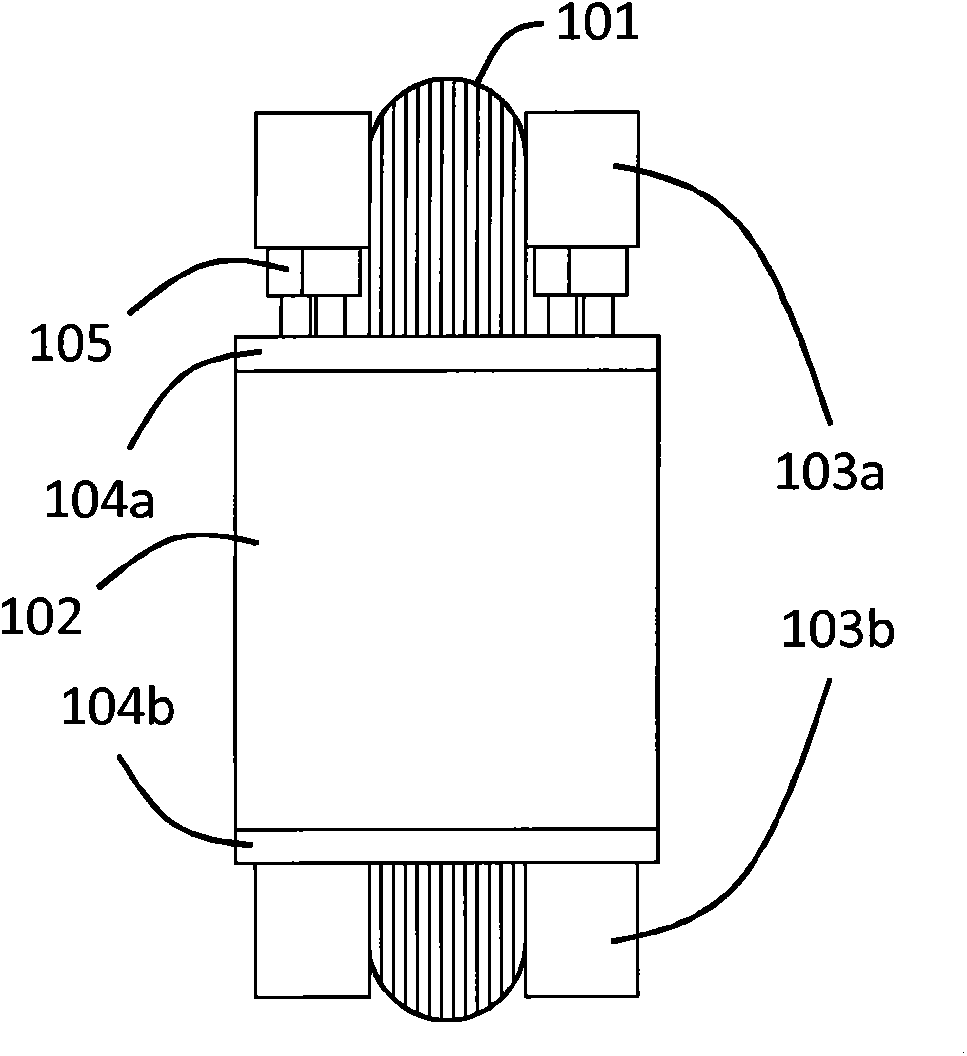

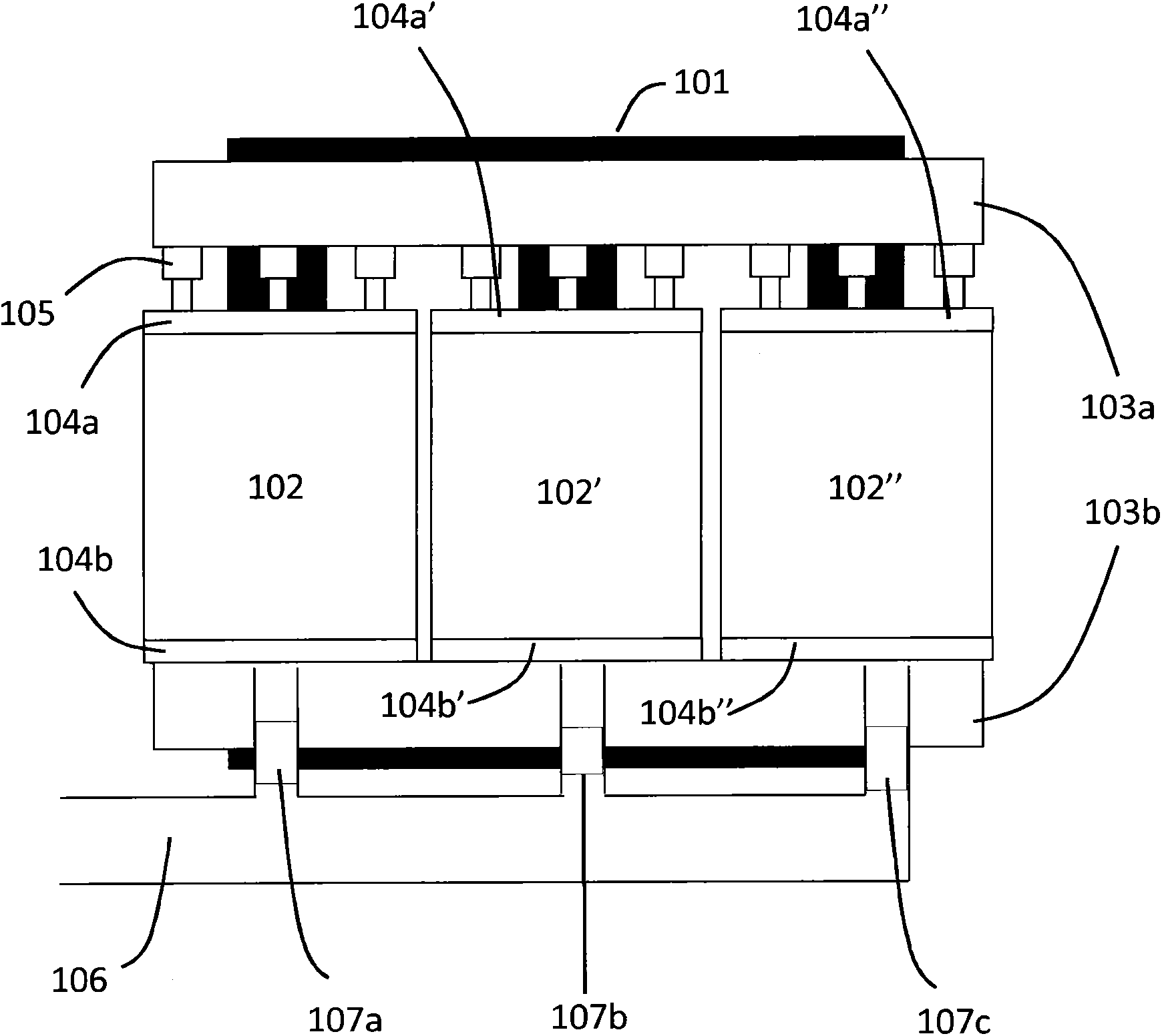

[0024] figure 1 Illustrated is the pressing of the movable part of the transformer, ie the pressing of the windings mounted to the transformer core, according to one embodiment of the invention. figure 1 A three-phase transformer core 101 is shown having three legs 108, 108', 108" each coaxially mounted with a set of windings 102, 102', 102". In addition, an upper core clamp 103a and a lower core clamp 103b are mounted to the core to stabilize the core and hold the core together. Core clamps are further used to help apply individual clamping pressures to the respective winding sets 102, 102', 102". During the drying of the movable parts of the transformer, the upper and lower platens 104a, 104a', 104a " and 104b, 104b', 104b" are respectively arranged to apply individual pressures to the respective winding sets, and to control the drying of the winding sets 102, 102 after the transformer is to be transported and when the transformer is in operation. ', cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com