Fig biscuit

A technology of figs and biscuits, applied in the field of biscuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: a kind of fig biscuit, is made up of following components and parts by weight: flour 60, fig 25, mallow 5, wild orchid 5, salt 2, tea seed oil 10, purified water amount,

[0013] Ripe fig fruit, fresh young mallow stems and leaves, and wild orchid leaves are selected, and an appropriate amount of pure water is added to make a slurry, then mixed with flour, salt, camellia seed oil, and purified water to prepare, stamped and baked. Temperature 200-300 degrees, bake for 4 minutes. An appropriate amount of purified water means that the above-mentioned raw materials are stirred and prepared into a slurry.

Embodiment 2

[0014] Embodiment 2: a kind of fig biscuit, is made up of following components and parts by weight: flour 50, fig 35, mallow 8, wild orchid 8, salt 1, tea seed oil 8, purified water amount,

[0015] Select ripe fig fruits, fresh young mallow stems and leaves, and wild orchid leaves in 90°C water with 20 grams of rock sugar and soak for 10 minutes, take them out, add an appropriate amount of pure water to make a slurry, and mix with flour, salt, and camellia seed oil , pure water, stirred and prepared, stamped and baked. Temperature 200-300 degrees, bake for 3 minutes. An appropriate amount of purified water means that the above-mentioned raw materials are stirred and prepared into a slurry. The soaking effect is to remove bitterness.

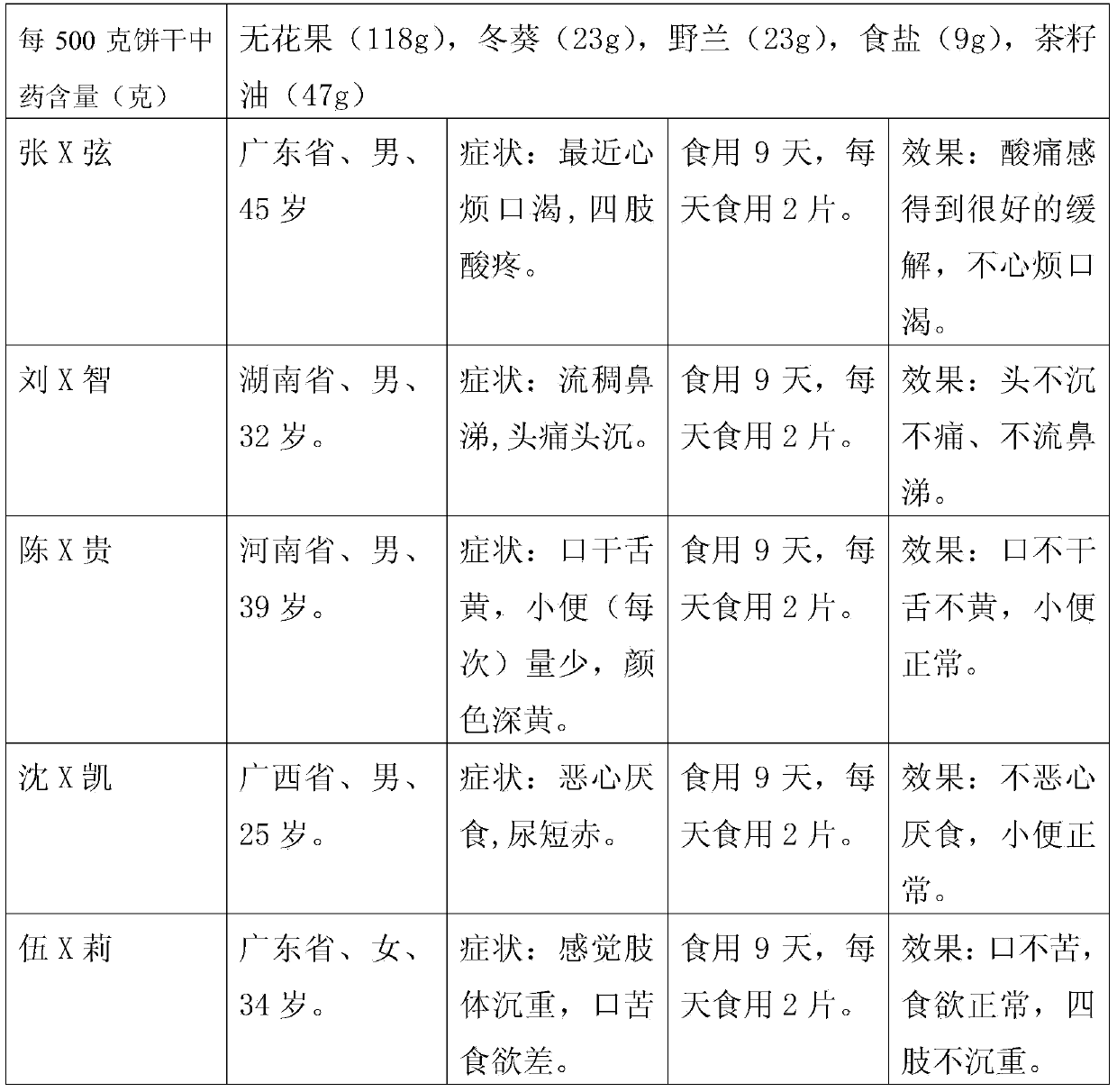

[0016] The present invention is used for 150 cases of damp-heat symptom people. They eat 2 small pieces of biscuits every day. After 9 days of eating, the diuretic and dehumidifying effects are obvious. The following are some specific examples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com