Apparatus and method for introducing circulating water for cooling hot air sterilizer

A circulating water cooling and dry heat sterilization technology, applied in the field of water circulating cooling, can solve the problems of high energy consumption, low production efficiency, and long cooling time, and achieve the effects of improving production efficiency, improving work efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

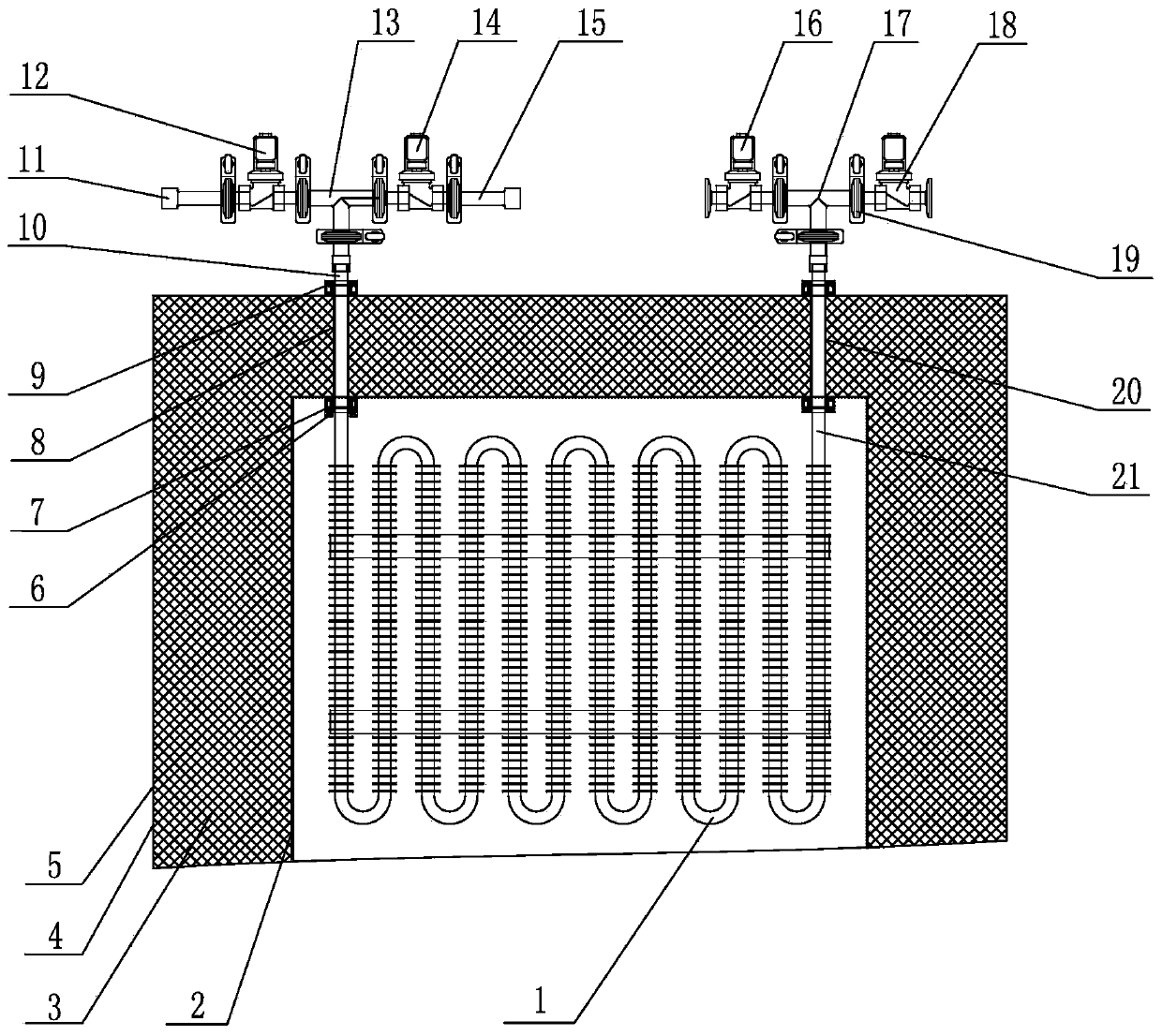

[0020] Such as figure 1 As shown, the dry heat sterilizer of the present invention is cooled by circulating water, comprising a shell, the shell includes an inner shell 2 and an outer shell 5, and an insulating layer 3 is arranged between the inner shell 2 and the outer shell 5 A cooler assembly 1 is arranged inside the inner casing 2, the water inlet pipe 10 of the cooler assembly 1 is connected to the water inlet tee joint 13 after passing through the first cooling connection pipe 8 arranged on the upper part of the casing, and the outlet pipe 21 of the cooler assembly 1 passes through The second cooling connection pipe 20 arranged on the upper part of the housing is connected to the water outlet tee joint 17, one end of the water inlet tee joint 13 is connected to the water inlet filter 11 through the water inlet control valve 12, and the other end of the wat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap