A spring press machine

A technology of a strong press and a pressure head, which is applied in the field of spring strong presses, can solve problems such as complex structure, achieve the effects of low labor intensity, various assembly forms, and ensure compression accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

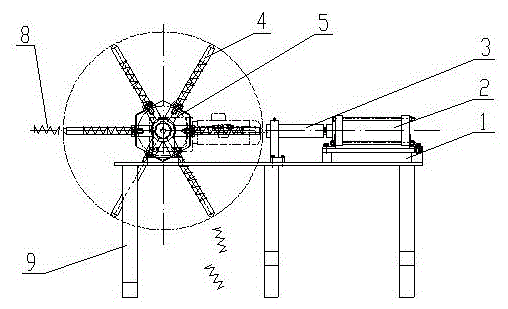

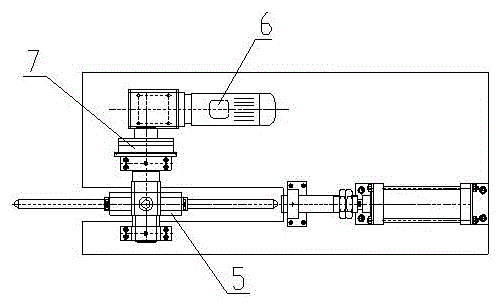

[0021] Embodiment one, see figure 1 , figure 2 , a spring press machine with a horizontal strong press structure, that is, the pressure head 3 is arranged horizontally. The workbench 9 is provided with a concave notch, the depth of which is greater than the radius of the circle formed by the drive disc 5 plus the workpiece string 4, and the two ends of the drive disc 5 are respectively fixed on the two ends of the workbench 9 concave notch by bearing seats. On the other hand, the driving disc 5 is vertically arranged, and 6 workpiece strings 4 are evenly distributed on its circumference, that is, the angle between the 6 workpiece strings 4 is 60 degrees. The drive disc 5 is connected with the speed reducer 6 of the drive device through the brake disc 7 .

[0022] The pressure head 3 is connected on the cylinder 2, and the cylinder 2 is fixed on the cylinder base 1, and the cylinder base 1 is installed horizontally against the concave notch.

[0023] When working, drive the...

Embodiment 2

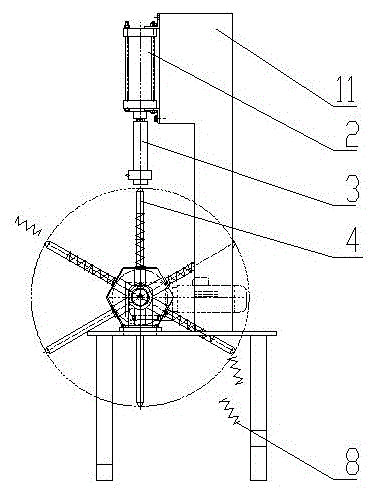

[0024] Embodiment two, see image 3 , a spring strong press machine with a vertical strong pressing structure, that is, the pressure head 3 is placed vertically. In order to ensure the balanced operation of the rotating drive disc 5, a concave gap is provided on the workbench 9. The drive disc 5 and the workpiece string rod 4 are fixed on both sides of the concave notch of the workbench 9 through the bearing seat, and the drive disc 5 is evenly distributed on the circumference of 6. The workpiece string rod 4, the drive disc 5 is connected with the speed reducer 6 of the driving device through the brake disc 7. The pressure head 3 is connected on the cylinder 2, and the cylinder 2 is fixed on the vertical cylinder base 11, and the bottom of the vertical cylinder base 11 is installed against the end of the concave notch.

[0025] The working process is basically the same as that of the first embodiment, the difference is that the pressure head 3 driven by the cylinder 2 recipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com