A kind of tubing cutter

A technology of tubing and cutter, applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of uneven tubing incision, stuck knife, broken knife, etc., and achieve the effect of neat tubing incision and no chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

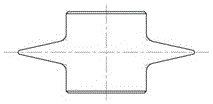

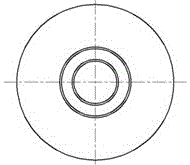

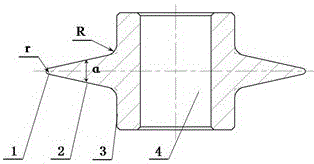

[0019] see Figure 1 to Figure 4 , the present invention relates to a pipe cutting tool, in particular to an oil pipe cutting tool, the specific structure of which is:

[0020] Including the tool body, the tool body extends from the root 3 to the blade 1 through the blade face 2, and the center of the cutter body is provided with a mounting hole 4; the blade face 2 is a full circle and the thickness of the blade face 2 gradually increases from the blade 1 to the blade root 3 . The blade 1, the blade surface 2 and the blade root 3 can rotate around the installation hole 4, and the blade 5 actively rotates around the center of the oil pipe 6 to be cut O Rotate, move radially towards the oil pipe on one side, and squeeze the oil pipe to realize cutting. Since the cutter adopts extrusion cutting, no chips are generated. Since the contact surface between the cutter and the oil pipe increases with the increase of the depth of cut, it can prevent the cutter from jamming due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com