Rapid scraping repair method of babbitt metal bearing bushing surface

A repair method, the technology of Babbitt alloy, which is applied in the field of bearing lining processing and repair, can solve the problems of long time-consuming scraping of the lining tile surface of Babbitt alloy bearings, and achieve the effect of reducing scraping repair time, reducing parking and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

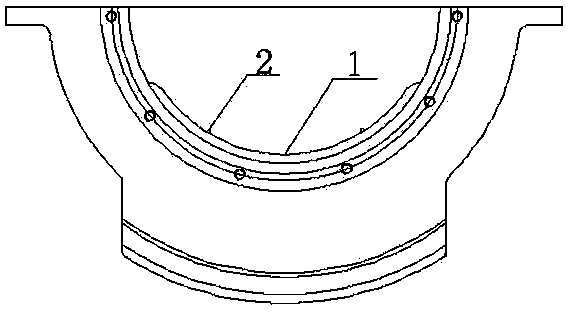

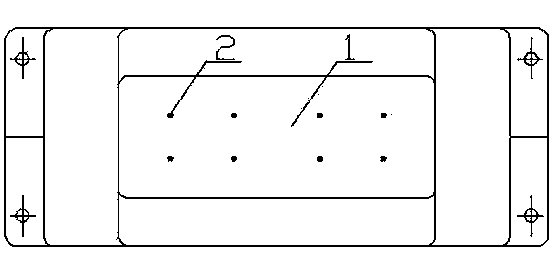

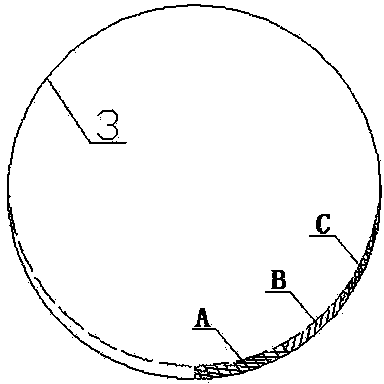

[0011] Such as figure 1 , 2 As shown, a quick scraping and repairing method for the lining tile surface of a Babbitt alloy bearing includes the following steps: Step 1, lightly poke 6-10 times on the bearing lining tile surface 1 with the tip of a triangular scraper to make the bearing lining tile surface Corresponding micro-protrusions 2 appear, and a row of micro-protrusions 2 is axially arranged at the bottom of the bearing lining surface 1, and 1-2 rows are arranged on both sides of the row in the axial direction according to the specifications of the bearing lining, and each row of micro-protrusions 2 There are 2-3; step 2, after grinding the hollow shaft 3 and the bearing lining tile surface 1, scrape according to the change of the micro-protrusion 2, the scraping volume of the micro-protrusion 2 is greater than that of the micro-protrusion 2 when it is ground or low on the tile surface 2 The scraping sales volume at the higher tile surface; the scraping sales volume de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com