A fully automatic multifunctional vegetable cutting machine

A multifunctional, vegetable cutting machine technology, applied in metal processing, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of not seeing products, achieve uniform thickness, simple mechanism structure, and facilitate cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

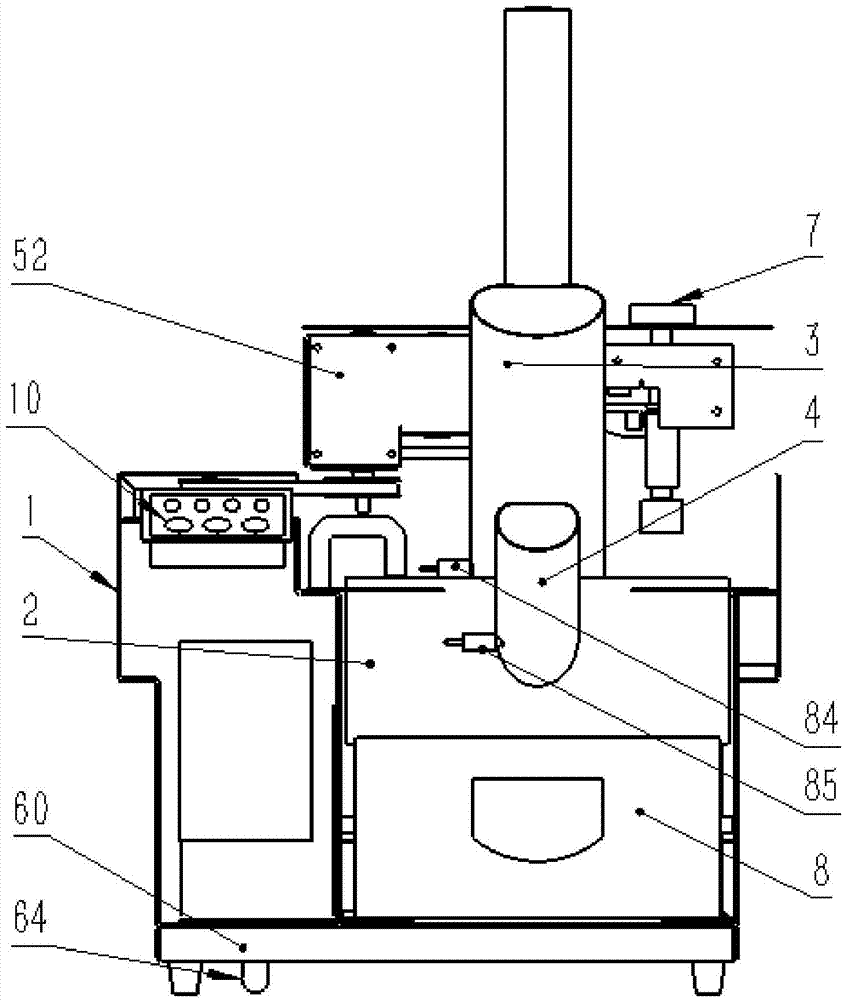

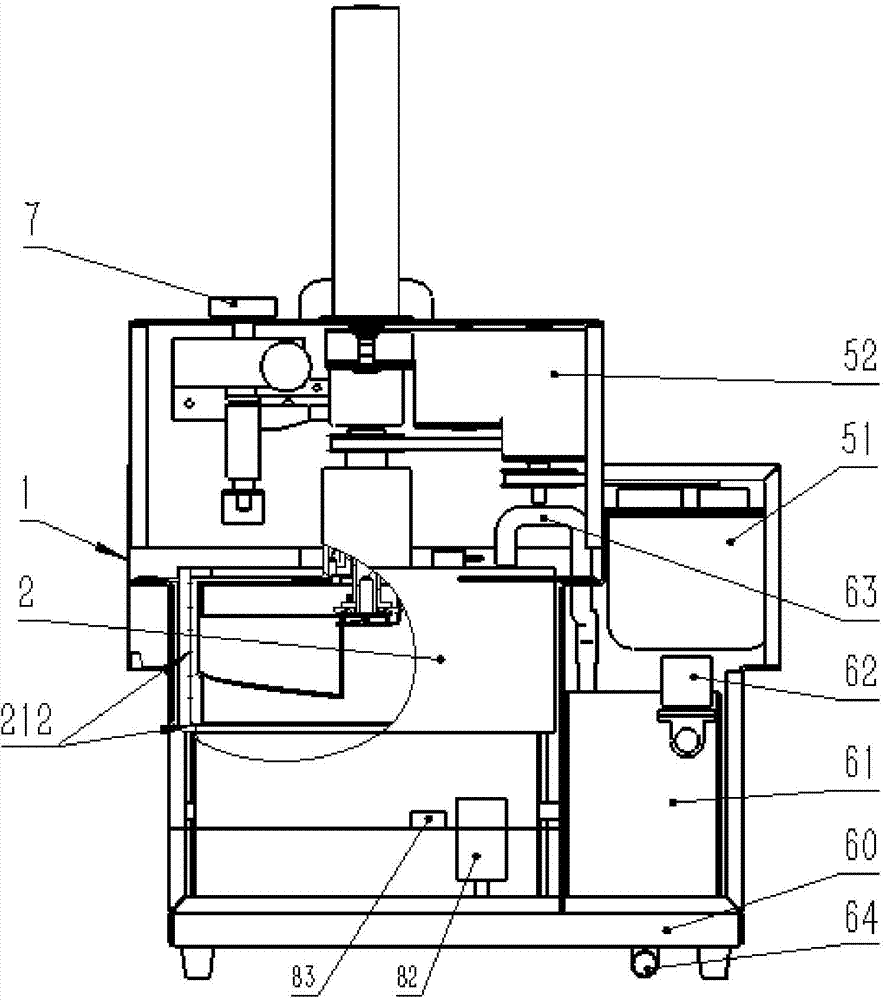

[0049] As shown in Figures 1 to 11, a vegetable cutter for a vegetable cutter includes four main mechanism systems including a cutter mechanism 2 installed in a chassis 1, a power device and a transmission mechanism, a cleaning system, and an operation and control system. And vegetable feeding cylinder 3, meat feeding cylinder 4, material box 8 etc.

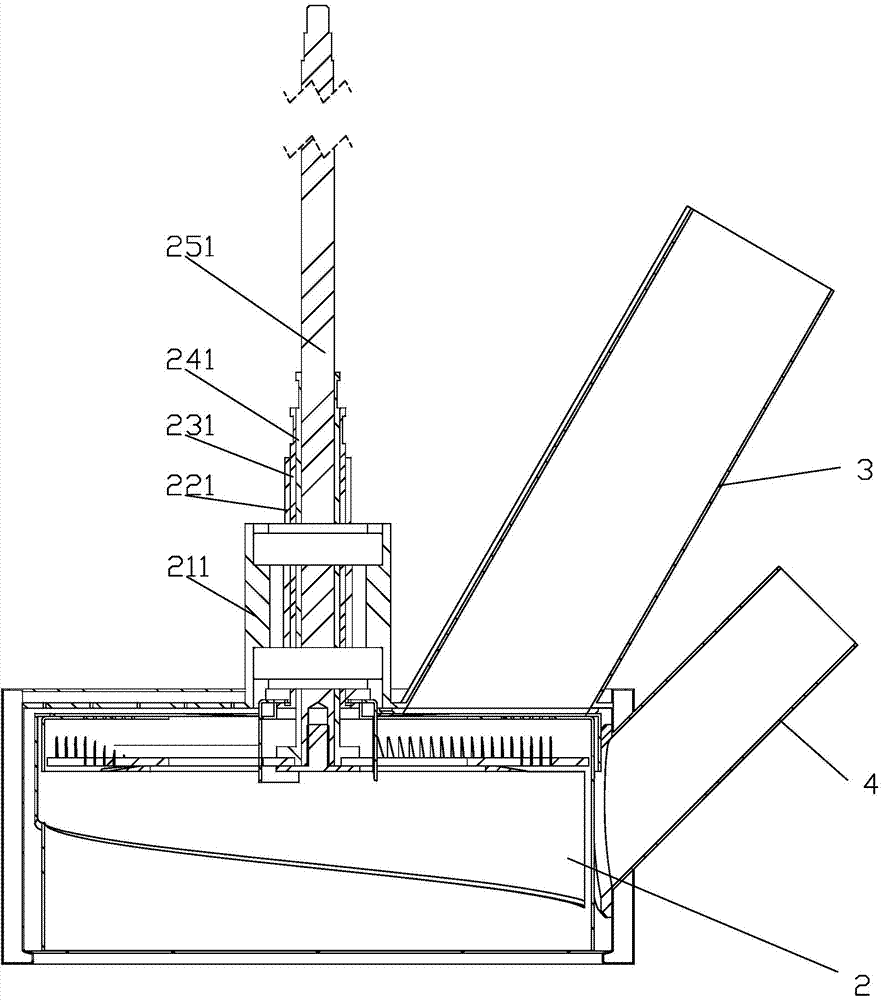

[0050] Such as image 3 As shown, the cutter mechanism 2: includes the main cutter group 22 installed in the cutter overcoat 21, the support plate 23, the comb knife 24, and the cutting reamer 25. The material mouth end is provided with material containing box 8.

[0051] Such as Figure 9 As shown, the cutter casing 21 is a cylinder with an open lower end, the end face of the cutter casing 21 is connected with the vegetable feed tube 3 , and the wall of the cutter casing 21 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com