Friction revolving barrel of helix freezing apparatus

A technology of freezing device and spiral, which is applied in the direction of household refrigeration device, lighting and heating equipment, cooler, etc., can solve the problems of food hygiene hazards, many metal materials, and difficult cleaning, so as to facilitate mass production, enhance bending resistance, Easy-to-rinse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

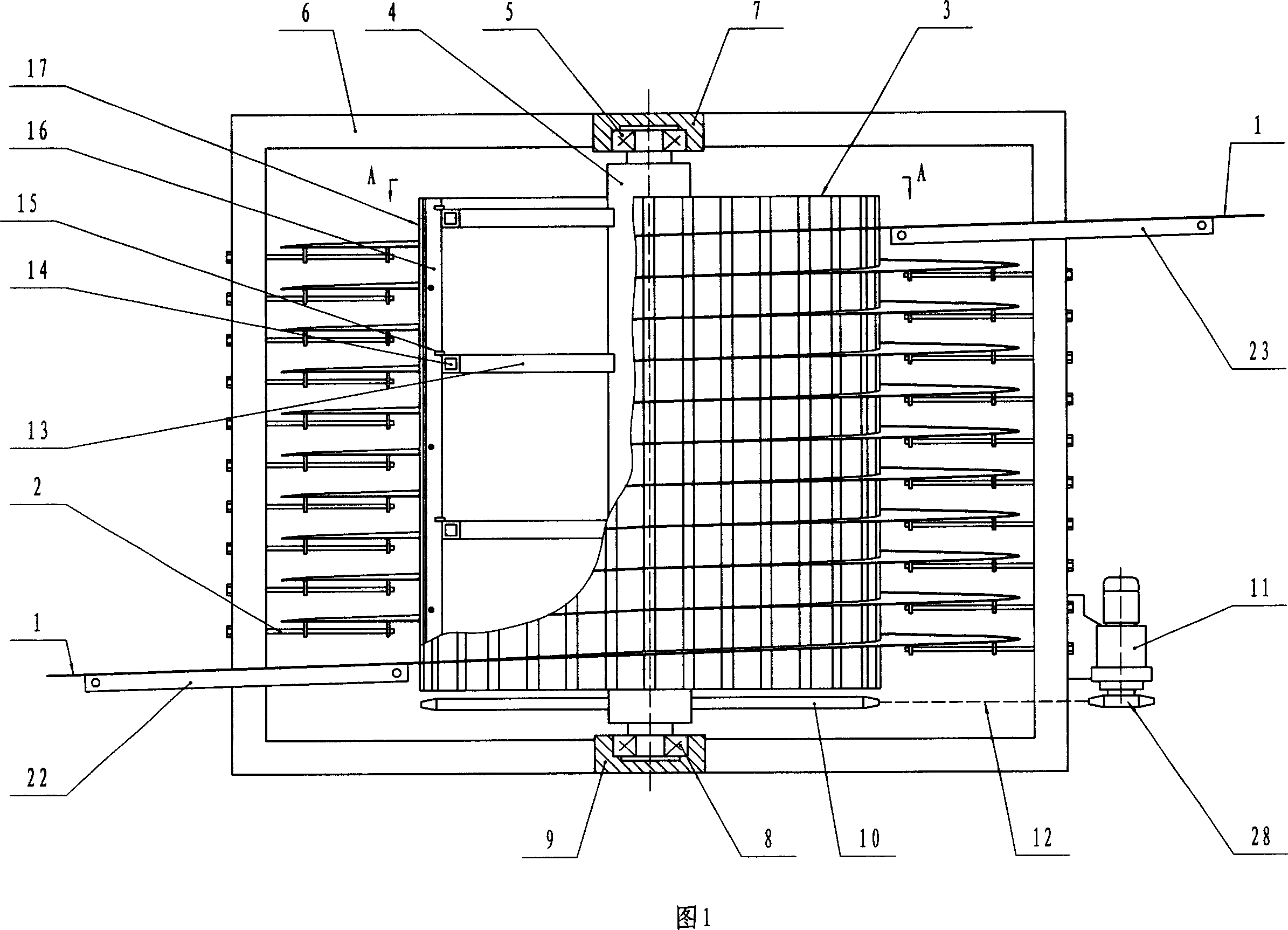

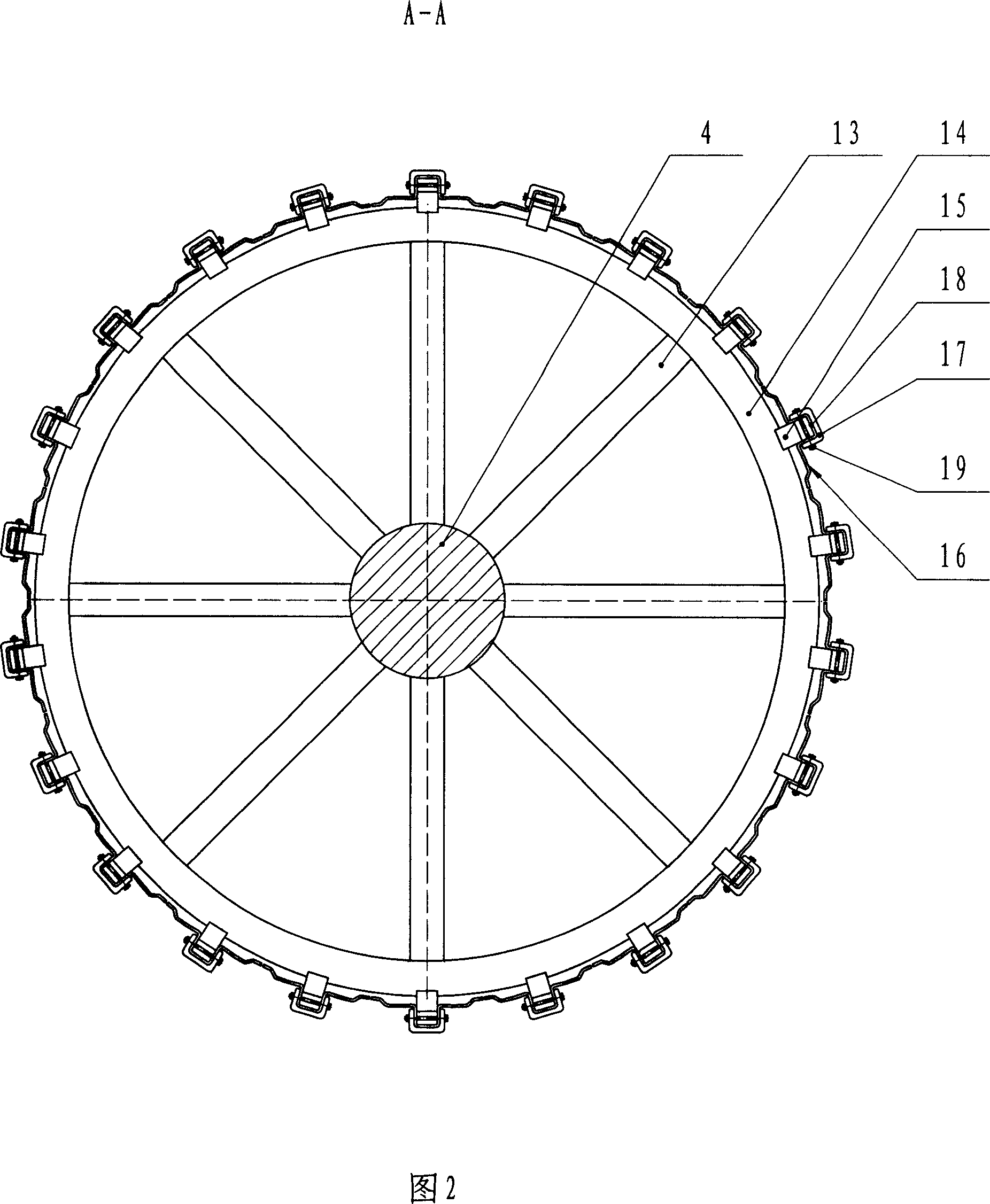

[0023] In the spiral freezing device, the friction drum 3 (see Figure 1) that drives the conveying mesh belt 1 carrying the frozen product to run along the spiral guide rail 2 includes a central shaft 4, and the upper end of the central shaft 4 is placed with a bearing 5 In the upper bearing seat 7 connected with the frame 6, the bearing 8 at the lower end of the central shaft 4 is placed in the lower bearing seat 9 connected with the frame 6, the central shaft 4 is equipped with a sprocket 10, and the sprocket 10 is connected to the The sprocket 28 on the output shaft of the electric reducer 11 on the frame 6 is connected and driven by the electric reducer 11, thereby driving the friction drum 3 to rotate, and the central shaft 4 is fixedly connected with at least two layers of cantilever 13 with radiation distribution , it is four layers in Fig. 1, and the outer end of the cantilever 13 of every layer of radiation distribution is connected with an annular frame 14, and the ou...

Embodiment 2

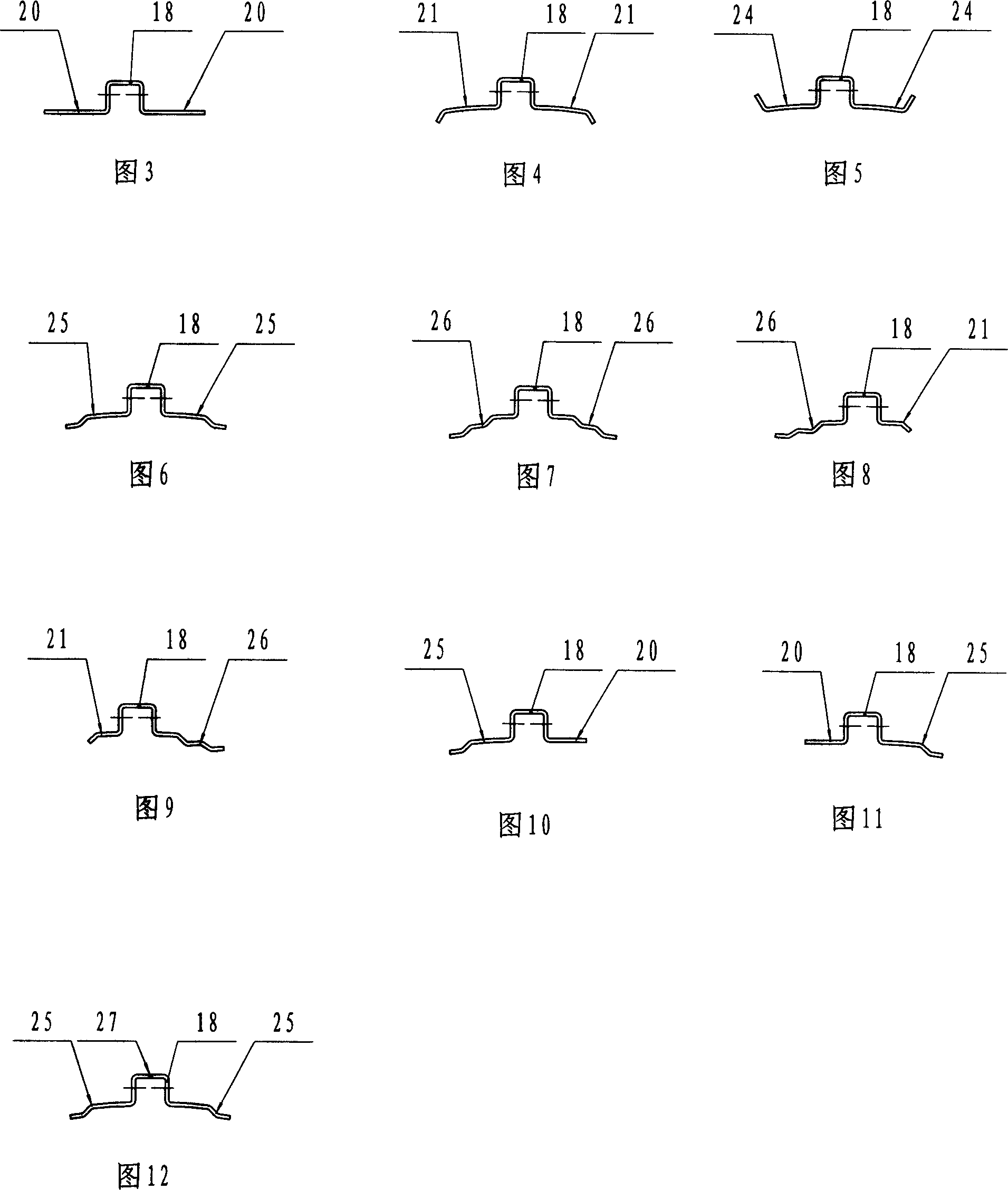

[0025] The difference from Embodiment 1 is that in order to improve the structural stability of the straight frame 16 with wind-shielding sides, the two wind-shielding sides of the straight-bar skeleton 16 with wind-shielding sides are windshields bent inward once respectively. Edge 21 (seeing Fig. 4) or the windshield edge 24 (seeing Fig. 5) that bends once outwards, 18 among Fig. 4, Fig. 5 is boss.

Embodiment 3

[0027] The difference from Embodiment 1 or 2 is that in order to improve the structural stability of the straight frame 16 with the windshield, the two windshield sides of the straight frame 16 with the windshield are respectively bent two times. Wind edge 25 (seeing Fig. 6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com