A kind of plywood preparation system and method

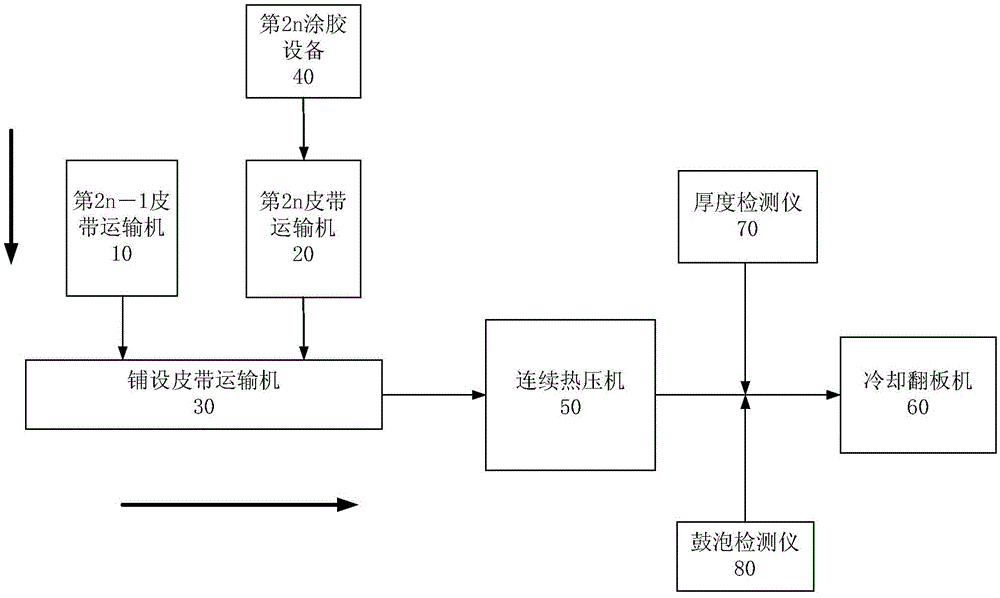

A preparation system and a technology for plywood, applied in the field of plywood preparation system, can solve the problems of inability to continuously assemble composite slabs, incapable of continuous hot pressing, etc., and achieve the effects of protecting health, saving manpower and labor, and increasing or decreasing quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also proposes a plywood preparation method, the method utilizes the above-mentioned plywood preparation system to prepare plywood, and the method includes:

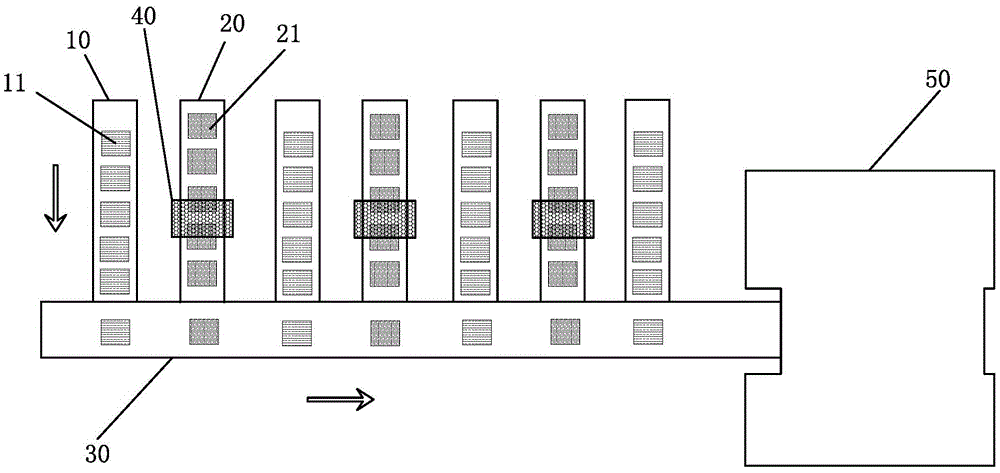

[0059] S10. The 2n-1th vacuum suction cup spreader places the 2n-1th veneer 11 on the 2n-1th belt conveyor 10, and the 2n-1th belt conveyor 10 places the 2n-1th layer veneer 11 Layer veneer 11 is transported on the described laying belt conveyor 30;

[0060] S20. The 2nth vacuum chuck lifter places the 2nth veneer 21 in the 2n gluing device 40 to complete the upper surface and lower surface gluing, and places the 2nth veneer 21 on the On the 2nth belt conveyor 20, the 2nth belt conveyor 20 transports the 2nth layer of veneers 21 coated with glue to the laying belt conveyor 30, and alternately stacks them with the 2n-1th layer of veneers 21 in sequence forming a composite slab, and the veneer 21 of the 2nth layer is perpendicular to the grain of the veneer 20 of the 2n-1th layer;

[0061] Whe...

Embodiment 1

[0073] 1. Main materials: New Zealand radiata pine veneer, urea-formaldehyde glue.

[0074] 2. Main equipment:

[0075] 1) Roller gluing machine: four-roller double-sided gluing machine, model: SDJ2700, manufactured by Germany Dieffenbacher Machinery Equipment Co., Ltd.

[0076] 2) Moisture content detector: Model: IR3000, manufactured by Grecon Automatic Detection and Control Equipment Co., Ltd.

[0077] 3) Continuous heat press machine: Double steel belt continuous heat press machine, model: CPS150-50.00 / Plywood, manufactured by German Dieffenbacher Mechanical Equipment Co., Ltd.

[0078] 4) Thickness detector: three-measurement track thickness detector, model: DMR / L3000, manufactured by Germany Dieffenbacher Mechanical Equipment Co., Ltd.

[0079] 5) Bubble detector: six-track bubbling detector, model: UPU3000, manufactured by Germany Dieffenbacher Mechanical Equipment Co., Ltd.

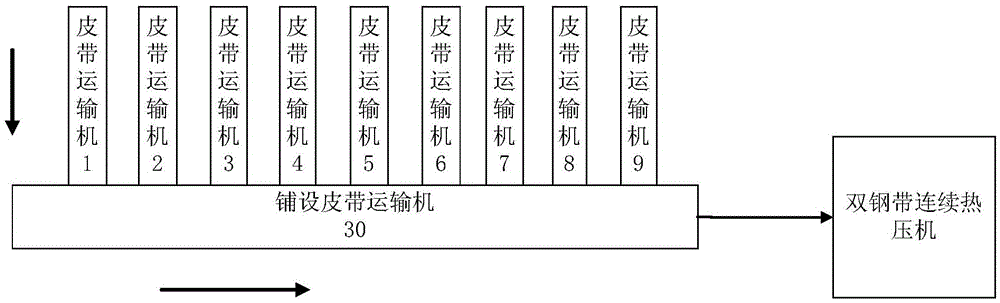

[0080] see image 3, to prepare 9 layers of pine plywood in this embodiment, five 2n-1 bel...

Embodiment 2

[0093] 1. Main materials: poplar veneer, phenolic glue, veneer.

[0094] 2. Main equipment:

[0095] 1) Roller gluing machine: four-roller double-sided gluing machine, model: SDJ2700, manufactured by Germany Dieffenbacher Machinery Equipment Co., Ltd.

[0096] 2) Moisture content detector: Model: IR3000, manufactured by Grecon Automatic Detection and Control Equipment Co., Ltd.

[0097] 3) Continuous heat press machine: Double steel belt continuous heat press machine, model: CPS150-50.00 / Plywood, manufactured by German Dieffenbacher Mechanical Equipment Co., Ltd.

[0098] 4) Thickness detector: three-measurement track thickness detector, model: DMR / L3000, manufactured by Germany Dieffenbacher Mechanical Equipment Co., Ltd.

[0099] 5) Bubble detector: six-track bubbling detector, model: UPU3000, manufactured by Germany Dieffenbacher Mechanical Equipment Co., Ltd.

[0100] see Figure 4 , the present embodiment will prepare 7 layers of poplar plywood, need 3 2n-1 belt conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com