Follow-up backflow preventer

A backflow preventer and follow-up technology, applied in the direction of functional valve types, engine components, pipe components, etc., can solve the problems of large resistance, reduce spring elastic resistance, fail to eliminate spring elastic resistance, etc., achieve constant performance and reduce resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

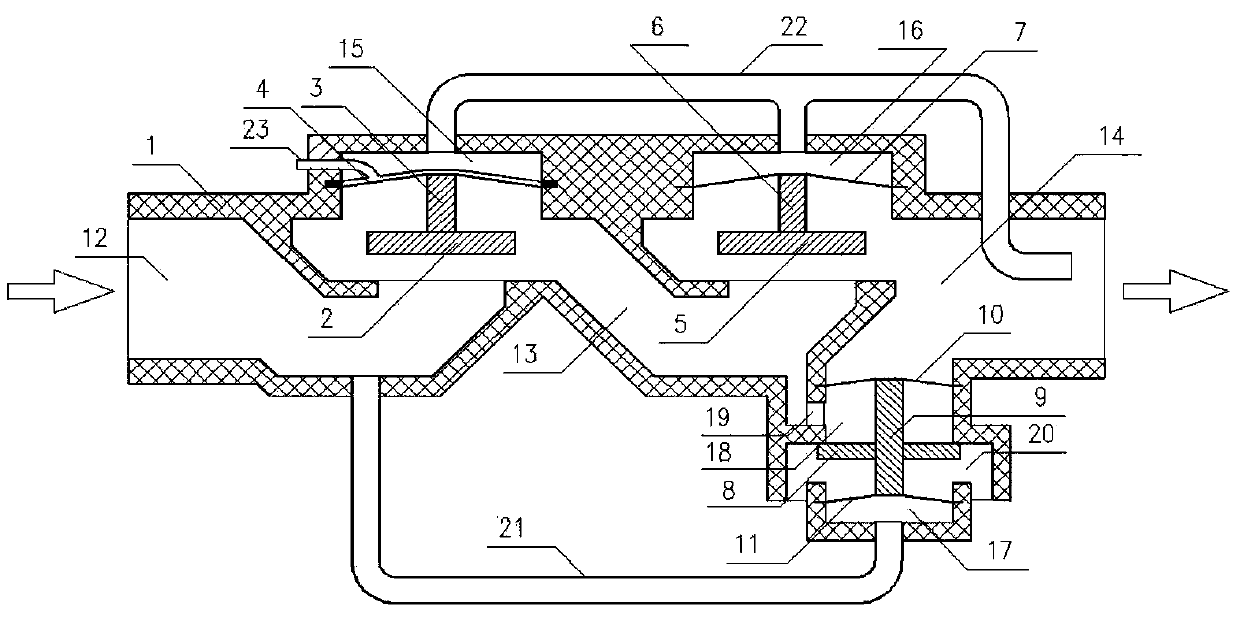

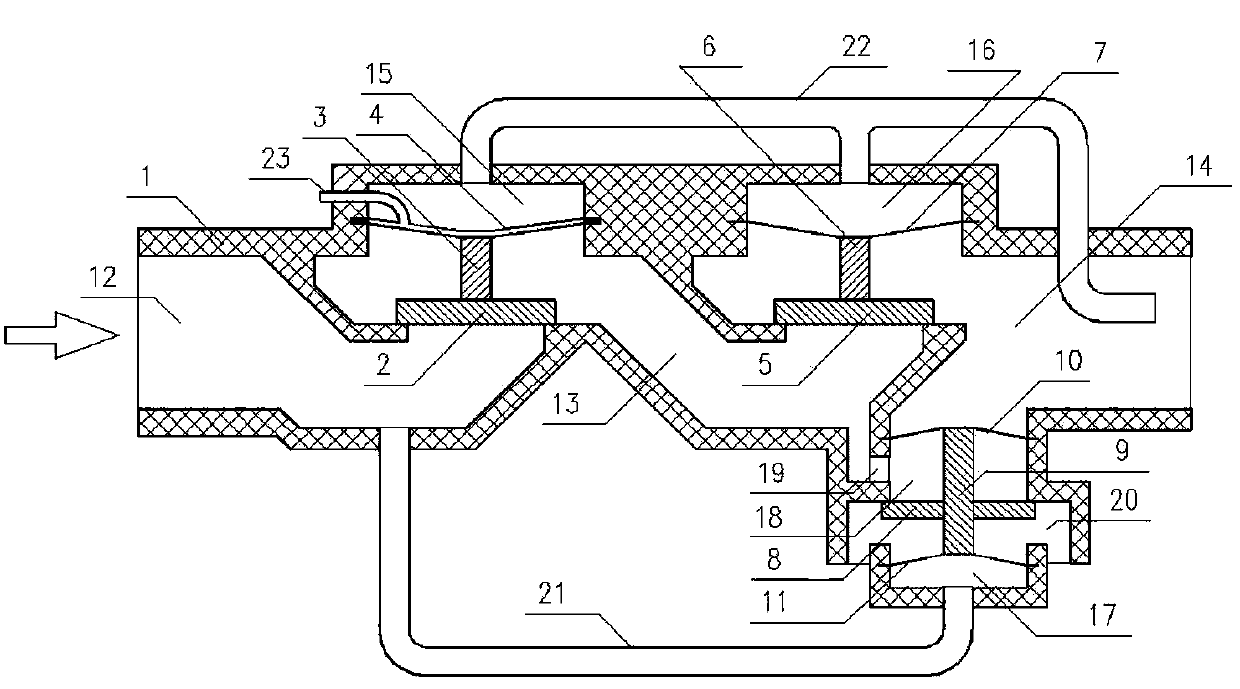

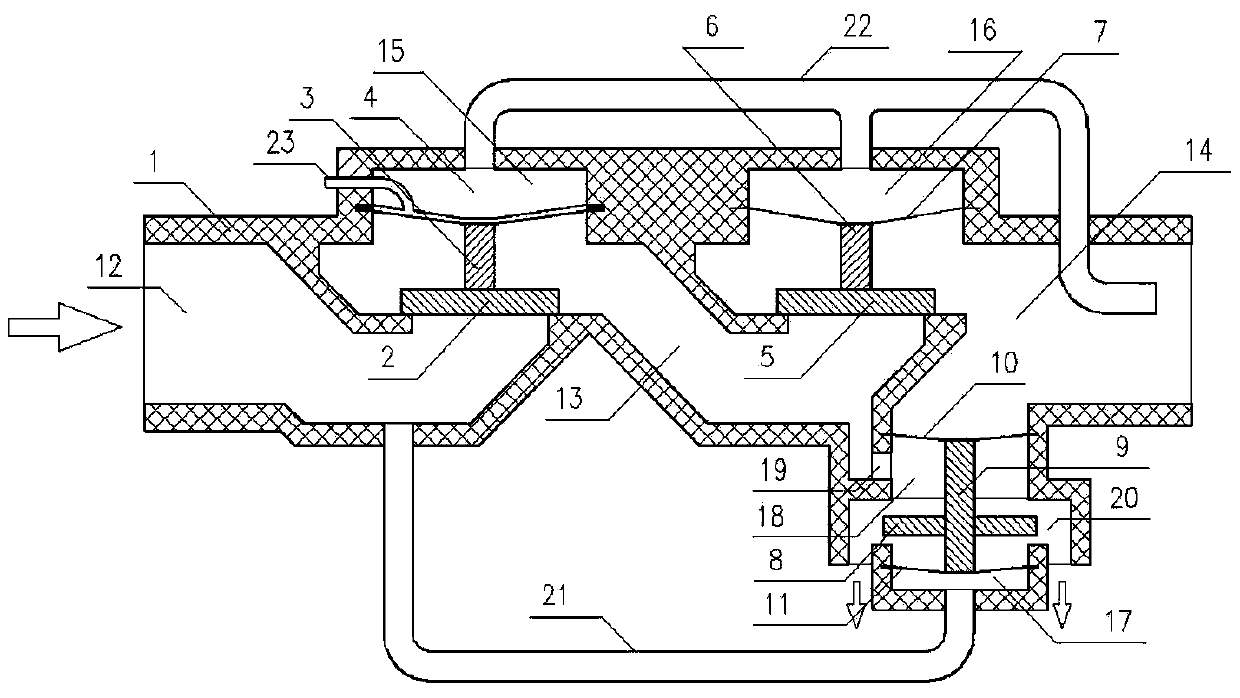

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] 1. Workflow

[0028] The working process of the present invention is divided into circulation working condition, closed working condition, low water pressure working condition, drainage working condition and reset working condition, which are described as follows:

[0029] 1. Circulation conditions

[0030] Such as figure 1 Shown: When the water pressure in the water inlet chamber 12 is higher than the set value, that is, when the water pressure is turned on, the force of the water is greater than the gravity of the gravity check valve 1 2 and the gravity check valve 2 5, and the gravity check valve 1 2 The gravity check valve 2 and 5 are fully opened successively, so that water can flow through the water inlet chamber 12, the valve chamber 13 to the water outlet chamber 14 smoothly. When water flows, on the flow process from the water inlet chamber 12 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com