A polyurethane composite board

A composite board and polyurethane technology, which is applied in the direction of building components, lamination, insulation, etc., can solve the problem of reducing the mechanical strength of polyurethane rigid foam plastics, compressive strength, long-term creep performance and dimensional stability, increasing cell size, and reducing polyurethane Rigid foam plastics use performance and other issues, to improve the gel time, reduce thermal conductivity, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

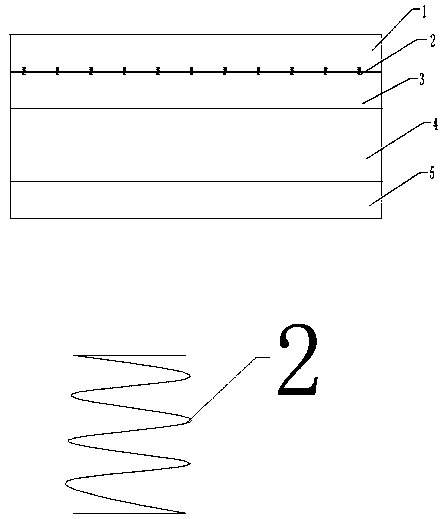

[0025] like figure 1 As shown, a polyurethane composite board includes a panel layer 1, a carbon foam layer 3, a polyurethane material layer 4, an aluminum foil plate 5, the lower surface of the panel layer 1 is connected to the carbon foam layer 3, and a buffer portion 2 is also arranged therebetween, and the carbon foam layer The lower surface of the foam layer 3 is connected to the polyurethane material layer 4 , the lower surface of the polyurethane material layer 4 is connected to the aluminum foil plate 5 , and the buffer portion 2 is evenly distributed between the panel layer 1 and the carbon foam layer 3 .

[0026] exist figure 1 Among them, the panel layer 1 has a built-in rib structure, the thickness of the panel layer 1 is 15mm, and the thickness of the carbon foam layer 3 is 15mm. It is made of resin-based carbon foam, and granular silicon carbide reinforcements are added to the carbon foam. The polyurethane material layer 4 The thickness is 40mm, the thickness of...

Embodiment 2

[0036] like figure 1 As shown, a polyurethane composite board includes a panel layer 1, a carbon foam layer 3, a polyurethane material layer 4, an aluminum foil plate 5, the lower surface of the panel layer 1 is connected to the carbon foam layer 3, and a buffer portion 2 is also arranged therebetween, and the carbon foam layer The lower surface of the foam layer 3 is connected to the polyurethane material layer 4 , the lower surface of the polyurethane material layer 4 is connected to the aluminum foil plate 5 , and the buffer portion 2 is evenly distributed between the panel layer 1 and the carbon foam layer 3 .

[0037] exist figure 1 Among them, panel layer 1 has a built-in stiffener structure. The thickness of panel layer 1 is 25mm, and the thickness of carbon foam layer 3 is 10mm. It is made of resin-based carbon foam, and granular silicon carbide reinforcements are added to the carbon foam. Polyurethane material layer 4 The thickness is 30mm, the thickness of the alumi...

Embodiment 3

[0047] like figure 1 As shown, a polyurethane composite board includes a panel layer 1, a carbon foam layer 3, a polyurethane material layer 4, an aluminum foil plate 5, the lower surface of the panel layer 1 is connected to the carbon foam layer 3, and a buffer portion 2 is also arranged therebetween, and the carbon foam layer The lower surface of the foam layer 3 is connected to the polyurethane material layer 4 , the lower surface of the polyurethane material layer 4 is connected to the aluminum foil plate 5 , and the buffer portion 2 is evenly distributed between the panel layer 1 and the carbon foam layer 3 .

[0048] exist figure 1 Among them, panel layer 1 has a built-in stiffener structure. The thickness of panel layer 1 is 20mm, and the thickness of carbon foam layer 3 is 20mm. It is made of resin-based carbon foam, and granular silicon carbide reinforcements are added to the carbon foam. Polyurethane material layer 4 The thickness is 50mm, the thickness of the alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com