Small-sized cable coiling tension control device

A technology of tension control and small size, which is applied in the field of tension control equipment for small size cable coils, which can solve problems such as hidden product quality, cable damage, and easy drop of cables, so as to improve the appearance of the coil and prevent personnel from Injuries and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

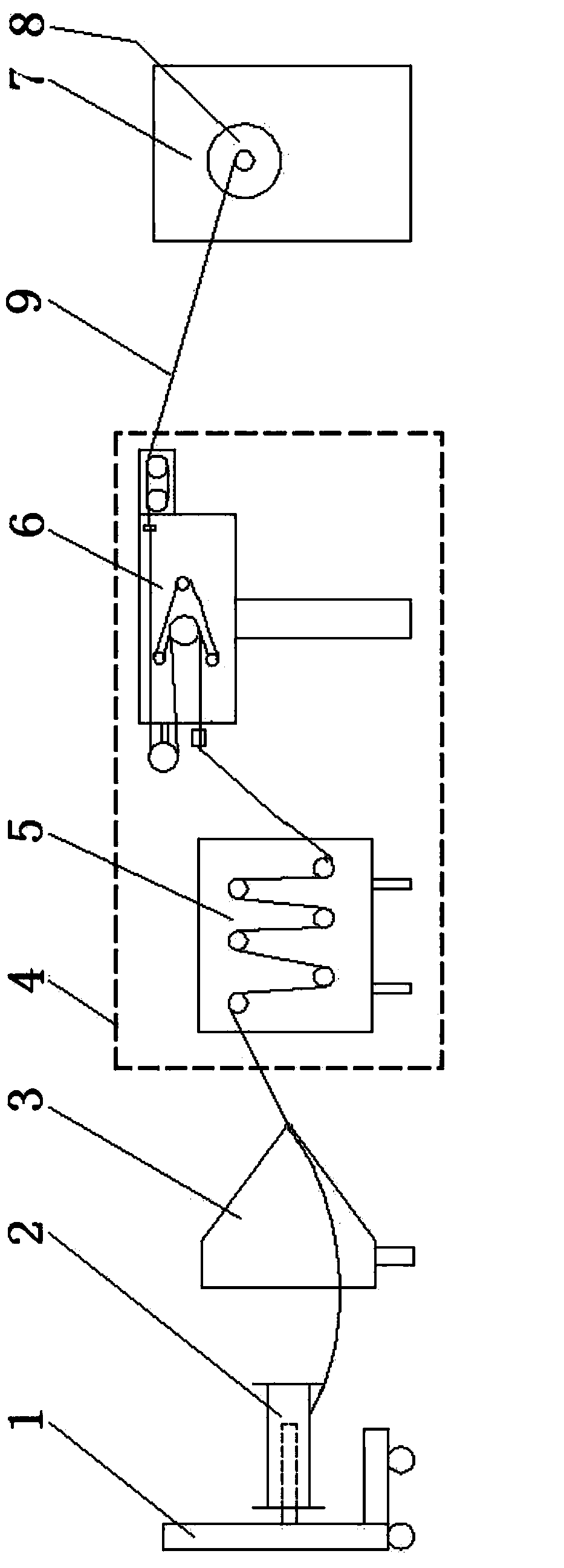

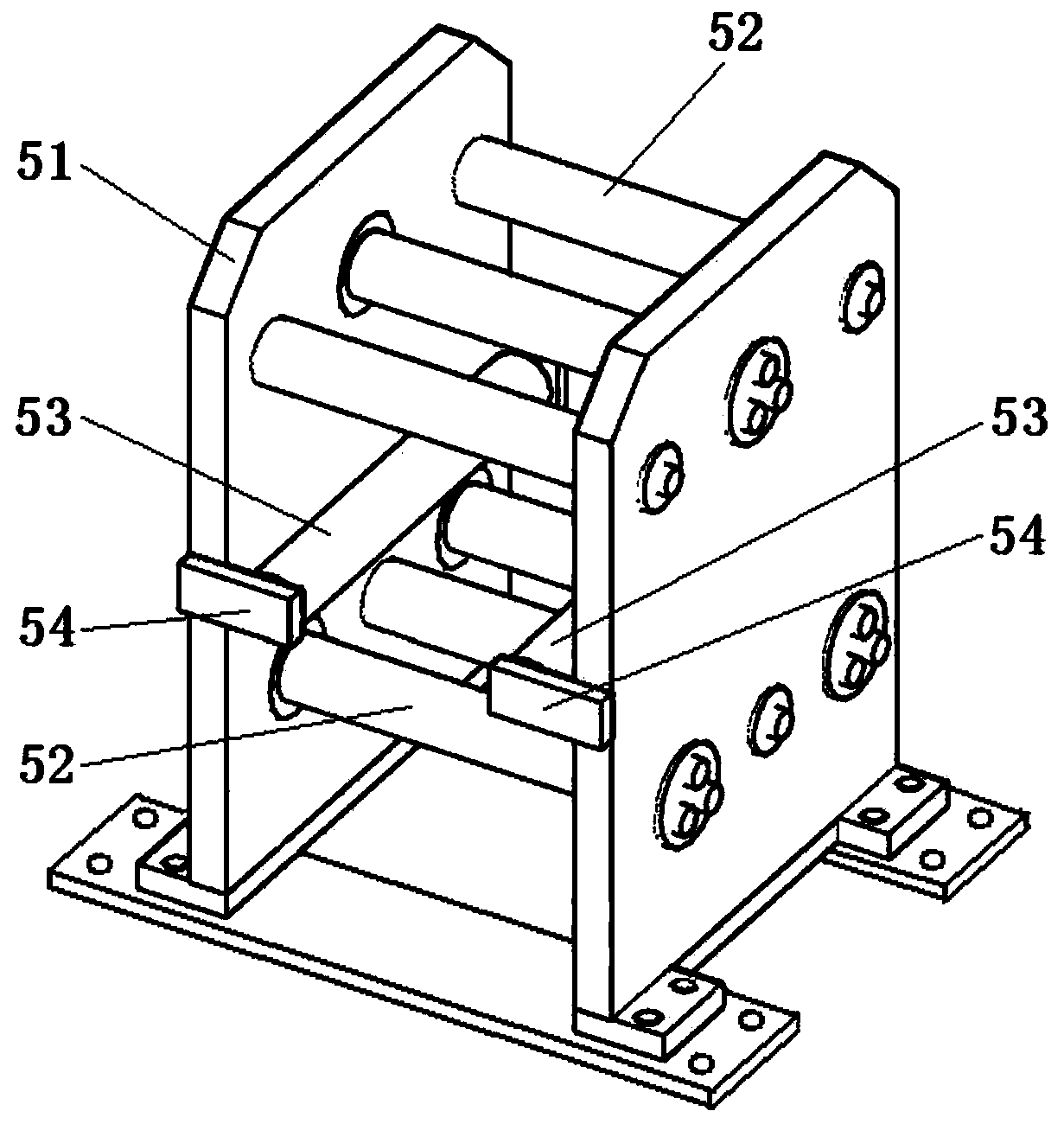

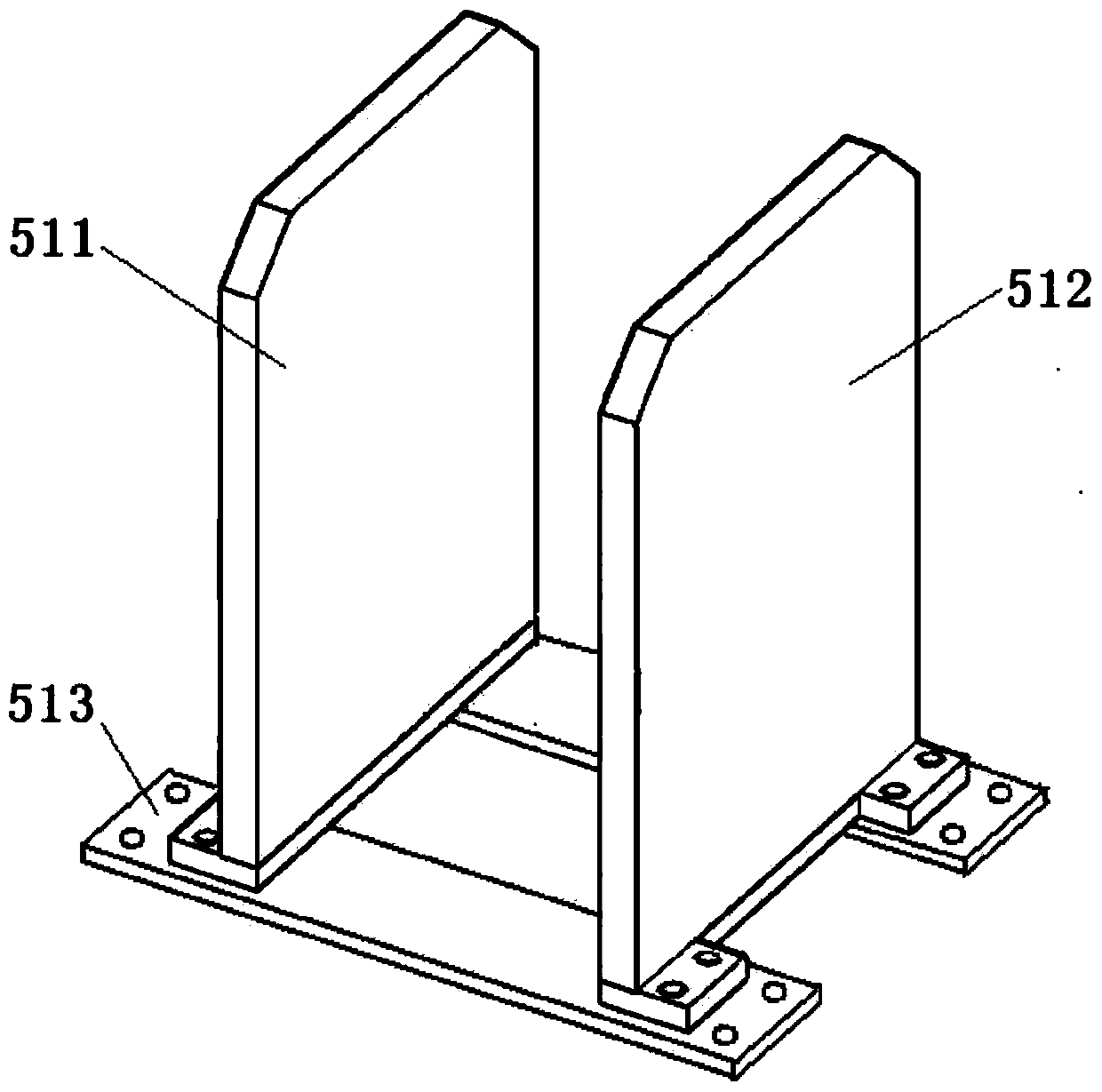

[0035] Embodiment 1 is a small-sized cable coiling tension control device composed of a straightening damping device, a tension meter and a wire breakage detection device. The three-dimensional structure diagram of the straightening damping device is as follows: Figure 2A As shown, the straightening damping device 5 is composed of a frame I 51 , a straightening roller 52 , a limiting roller 53 and a limiting roller bracket 54 . Figure 2B It is a schematic diagram of the frame of the straightening damping device. The left side plate 511 and the right side plate 512 are parallel to each other and relatively vertically fixed on the base I513 to form the frame I51. Such as Figure 2A As shown, two sets of straightening rollers 52 are respectively placed on the upper and lower parts of the frame I51, the left and right ends of the straightening rollers 52 are fixedly connected to the inner sides of the left side plate 511 and the right side plate 512 respectively, and the upper ...

Embodiment 2

[0042] Embodiment 2 is that the polyvinyl chloride jumper is formed into a disk, and the length of the disk is 100m, and the specific steps are:

[0043] The cable 9 is a polyvinyl chloride jumper. When the cable 9 on the large plate 2 is divided into the small size plate 8, first, the large plate 2 with the cable 9 is placed on the pay-off frame 1, and the wire The cable 9 passes through the spinning barrel 3 and the small-sized cable coiling tension control device 4 successively, and then the cable 9 is rewound on the small-sized coiling tool 8 installed on the coiling device 7 . Wherein, the cable 9 first passes through the straightening damping device 5 in the small-sized cable coiling tension control device 4, and then passes through the tension meter and disconnection detection device 6, and the sequence in the above two devices is:

[0044] 1) The cable 9 enters the straightening and damping device 5 after passing through the wire throwing barrel 3. In the straightening...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap