Air-resistance type rope guider for guiding large steel rope of boring winch

A drilling rig winch and air resistance technology, which is applied in the direction of the clockwork mechanism and the hoisting device, etc., achieves the effects of convenient maintenance, good rope arranging effect and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

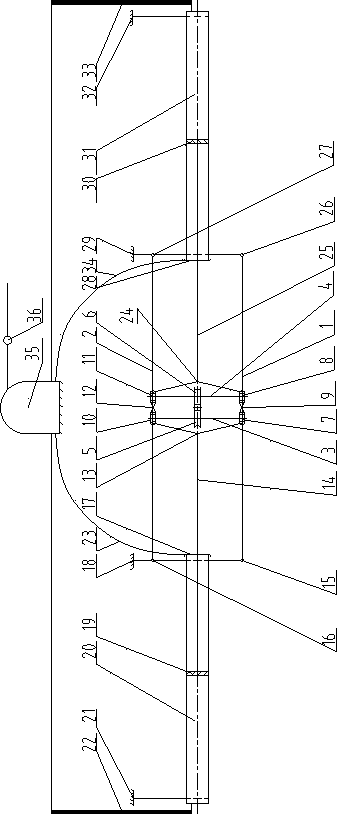

[0011] Such as figure 1 As shown, a drilling rig winch large-rope air-resistance type rope rower mainly consists of a front guide rod 1, a rear guide rod 2, a left rope wheel shaft 3, a right rope wheel shaft 4, a left rope wheel 5, and a right rope wheel 6. Front left guide sleeve 7, front right guide sleeve 8, front connecting sleeve 9, rear left guide sleeve 10, rear right guide sleeve 11, rear connecting sleeve 12, left support frame 13, left piston rod 14, left front guide rod bracket 15. Left rear guide rod bracket 16, left piston cover 17, left inner bracket 18, left piston 19, left piston barrel 20, left outer bracket 21, left rear air intake pipe 22, left front air intake pipe 23, right support frame 24, right piston Rod 25, right front guide rod support 26, right rear guide rod support 27, right piston cover 28, right inner support 29, right piston 30, right piston barrel 31, right outer support 32, right rear air intake pipe 33, right front air intake pipe 34, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com