A kind of preparation method of diethoxymethane

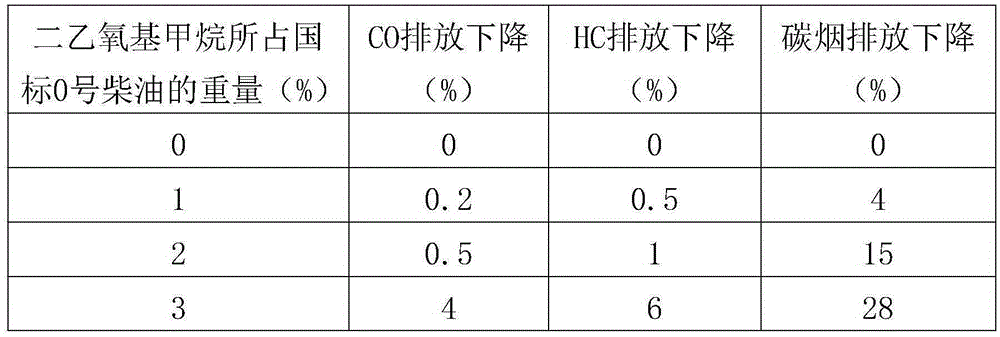

A technology of diethoxymethane and ethylenediaminetetraacetic acid, which is applied in the field of preparation of diethoxymethane, can solve the problems of excessive formaldehyde, long dissolution time, and poor yield, so as to improve economic benefits and reduce energy consumption , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

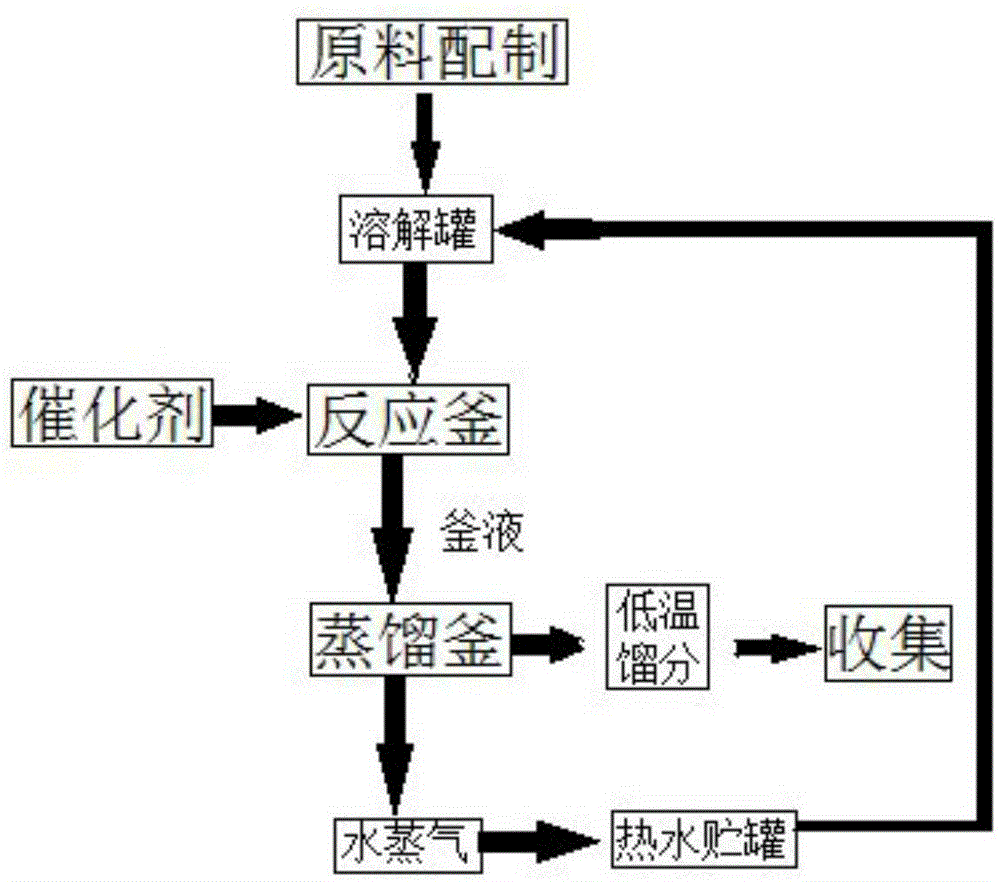

[0028] Such as figure 1 Shown, a kind of preparation method of diethoxymethane comprises the following steps:

[0029] (1) Raw material preparation: prepare ethanol and formaldehyde according to the ratio of ethanol / formaldehyde mass ratio of 3 to prepare raw material mixed solution;

[0030] (2) Dissolution: pump the mixed solution of raw materials in step 1) into the dissolution tank for dissolution, and then pump it into the reaction kettle;

[0031] (3) Reaction: add an organic catalyst into the reaction kettle and keep stirring to make the raw material solution react in the reaction kettle, and reflux for 3 hours at a temperature of 60°C to obtain the kettle liquid;

[0032] (4) Distillation: After passing the inspection of the still liquid obtained in step 3), transfer it to the still still for distillation treatment. During the distillation process, collect the condensed fraction at 90°C, add dehydrating agent anhydrous magnesium sulfate to separate Discharge the liqu...

Embodiment 2

[0034] Such as figure 1 Shown, a kind of preparation method of diethoxymethane comprises the following steps:

[0035] (1) Raw material preparation: prepare ethanol and formaldehyde according to the ratio of ethanol / formaldehyde mass ratio of 4 to prepare raw material mixed solution;

[0036] (2) Dissolution: pump the mixed solution of raw materials in step 1) into the dissolution tank for dissolution, and then pump it into the reaction kettle;

[0037] (3) Reaction: Add an organic catalyst into the reactor and keep stirring to make the raw material solution react in the reactor, and reflux for 2 hours at a temperature of 80°C to obtain the kettle liquid;

[0038] (4) Distillation: After passing the inspection of the still liquid obtained in step 3), transfer it to the still still for distillation treatment. During the distillation process, collect the condensed fraction at 60°C, add dehydrating agent anhydrous magnesium sulfate to separate Discharge the liquid and DEM produ...

Embodiment 3

[0040] According to Embodiment 1 or Embodiment 2, in order to satisfy the theoretical ratio of methanol to ethanol, so that the amount of raw materials can produce products and prevent formaldehyde residues in products, resulting in waste of raw materials, the mass ratio of ethanol / formaldehyde is 3.1, 3.2, 3.3 , 3.4, 3.5, 3.6, 3.7, 3.8, 3.85, 3.9, or 3.95.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com