A method for manufacturing an inner layer copper plate exposed copper of a power battery circuit board

A technology of power battery and manufacturing method, which is applied in the directions of secondary treatment of printed circuit, application of non-metallic protective layer, and formation of electrical connection of printed components, etc. Glue and other problems, to achieve the effect of improving production efficiency, high cutting efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

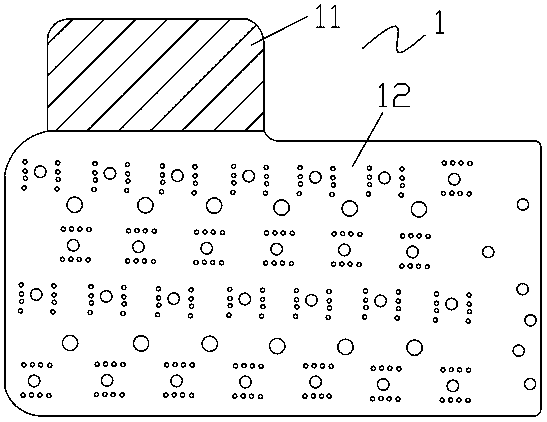

[0023] like figure 1 As shown, a method for manufacturing an inner layer copper plate exposed copper of a power battery circuit board includes the following specific steps:

[0024] S1. According to the customer's requirements, select a copper plate with a thickness of 1.5mm as the inner layer, process the copper plate, drill holes, and contour the copper plate, and use this copper plate as the inner layer plate 1. Wherein the inner layer board is composed of exposed copper area 11 and covering area 12; said exposed copper area is the area where metal copper is exposed after the finished circuit board is made, while the covering area is made into the cost circuit board and covered by the outer layer circuit board covered area.

[0025] S2. Surface treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com