Method for elastically restraining main beam displacement of ultrahigh-span cable-stayed bridge

An elastic constraint, cable-stayed bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of the impact of the main beam and the limit device, the large end displacement of the super-span cable-stayed bridge, etc., to improve the stress of the bridge structure. , Improve stability and safety, the effect of relative displacement mitigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

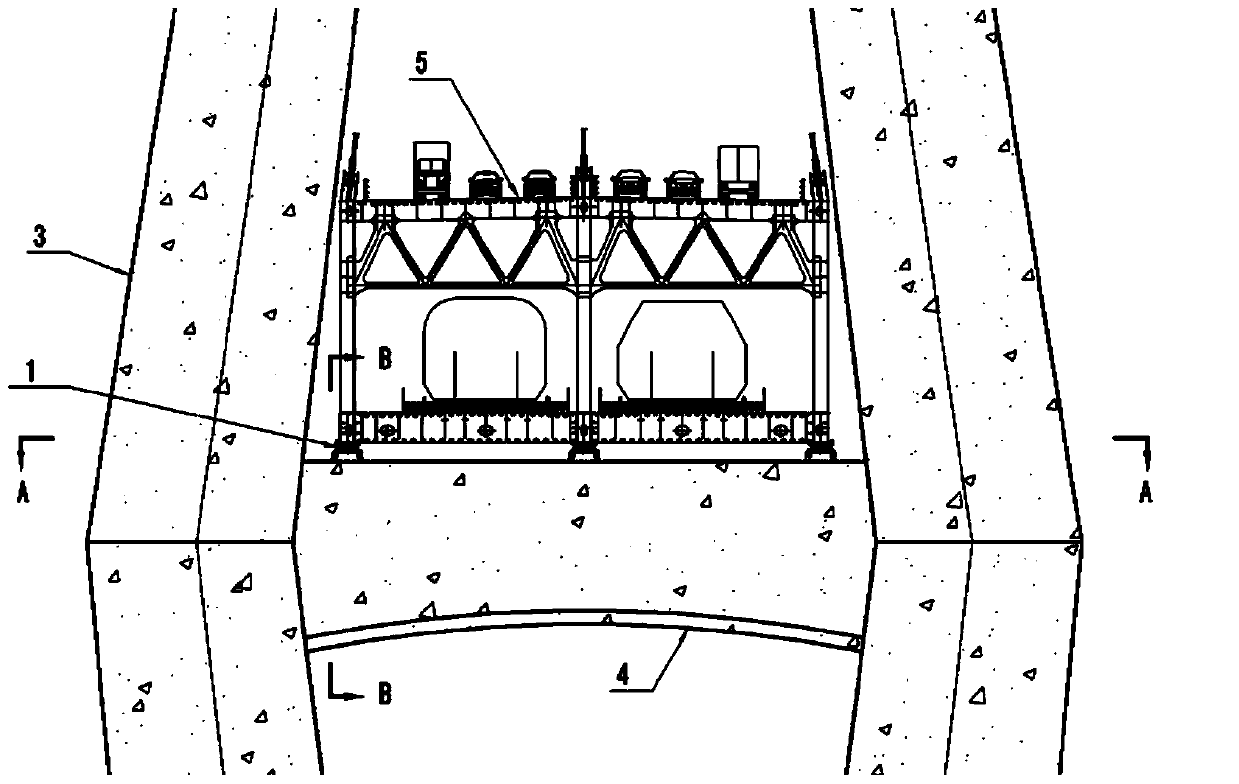

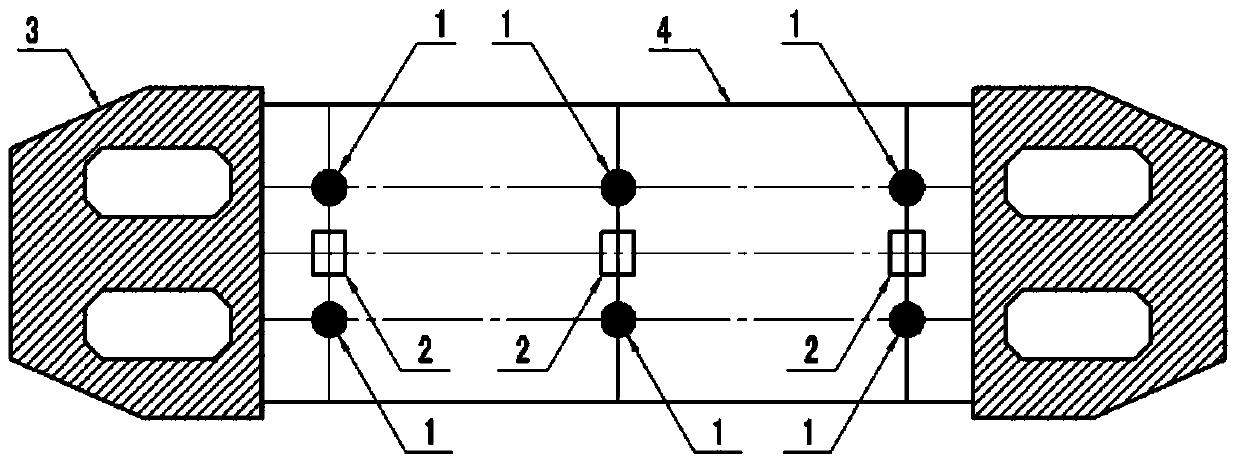

[0022] In the present invention, after the construction of the main tower 3 is completed, a permanent support is installed on the top surface of the main tower beam 4, the zero section of the main beam 5 is installed, a temporary consolidation is set between the main tower beam 4 and the main beam 5, and the main cantilever assembly is continued. From the beam to the maximum cantilever, install the spring device 1 on the top surface of the main tower beam 4 before the main beam 5 is closed, the upper connecting plate 6 of the spring device 1 is connected to the bottom surface of the main beam 5, and the lower connecting plate 8 is connected to the top surface of the main tower beam 4, After the main girder is closed, the temporary consolidation is released, and then the follow-up construction is carried out.

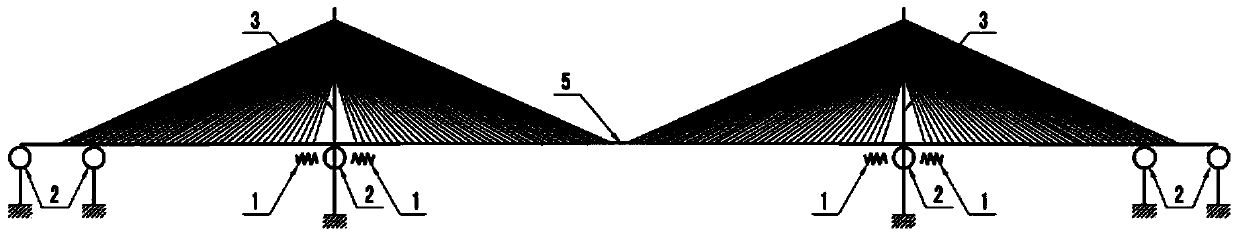

[0023] refer to figure 1 , figure 2 , the present invention arranges support 2 on the main tower beam top surface. A spring device 1 is arranged between the main towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com