Multi-cavity concrete filled steel tubular column with reinforcement cage and implementation method

A technology of steel pipe concrete columns and steel cages, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of insufficient material performance, decreased bearing capacity of cavity wall plates, and brittle core concrete, so as to improve the initial resistance. Lateral stiffness, improved compressive capacity and ductility, effect of increased capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

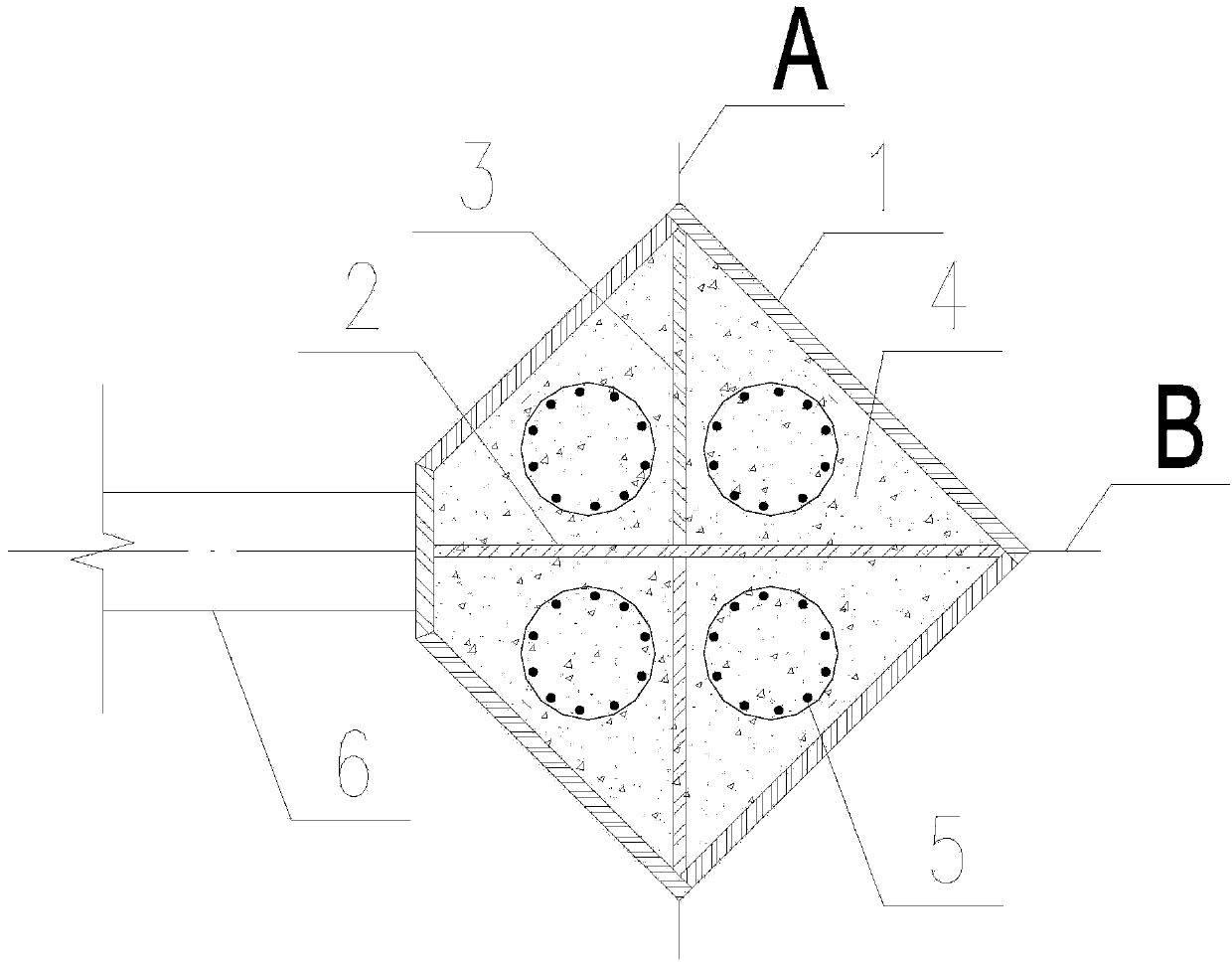

[0025] Such as figure 1 As shown, a multi-cavity steel pipe concrete column with a steel cage, wherein the multi-cavity steel pipe concrete column with a steel cage includes a polygonal steel pipe 1, an integral inner partition 2, an inner partition 3, concrete 4 and a steel cage 5.

[0026] The center of the polygonal steel pipe 1 is provided with an A-axis and a B-axis, the A-axis is the long diagonal direction of the polygonal steel pipe 1, and the B-axis is the short diagonal direction of the polygonal steel pipe 1; along the B-axis direction, the polygonal steel pipe 1 and the connecting member 6 Welding along the direction of the center line; the integral inner partition 2 is welded to both ends of the short diagonal of the polygonal steel pipe 1 along the direction of the B axis; the inner partition 3 is welded to both ends of the long diagonal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com