Motor-driven auxiliary lock

An electric auxiliary lock body technology, which is applied in the field of auxiliary locks, can solve the problem that there is no corresponding index for the airtightness of vehicles, and achieve the effect of good airtightness and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is further described in detail:

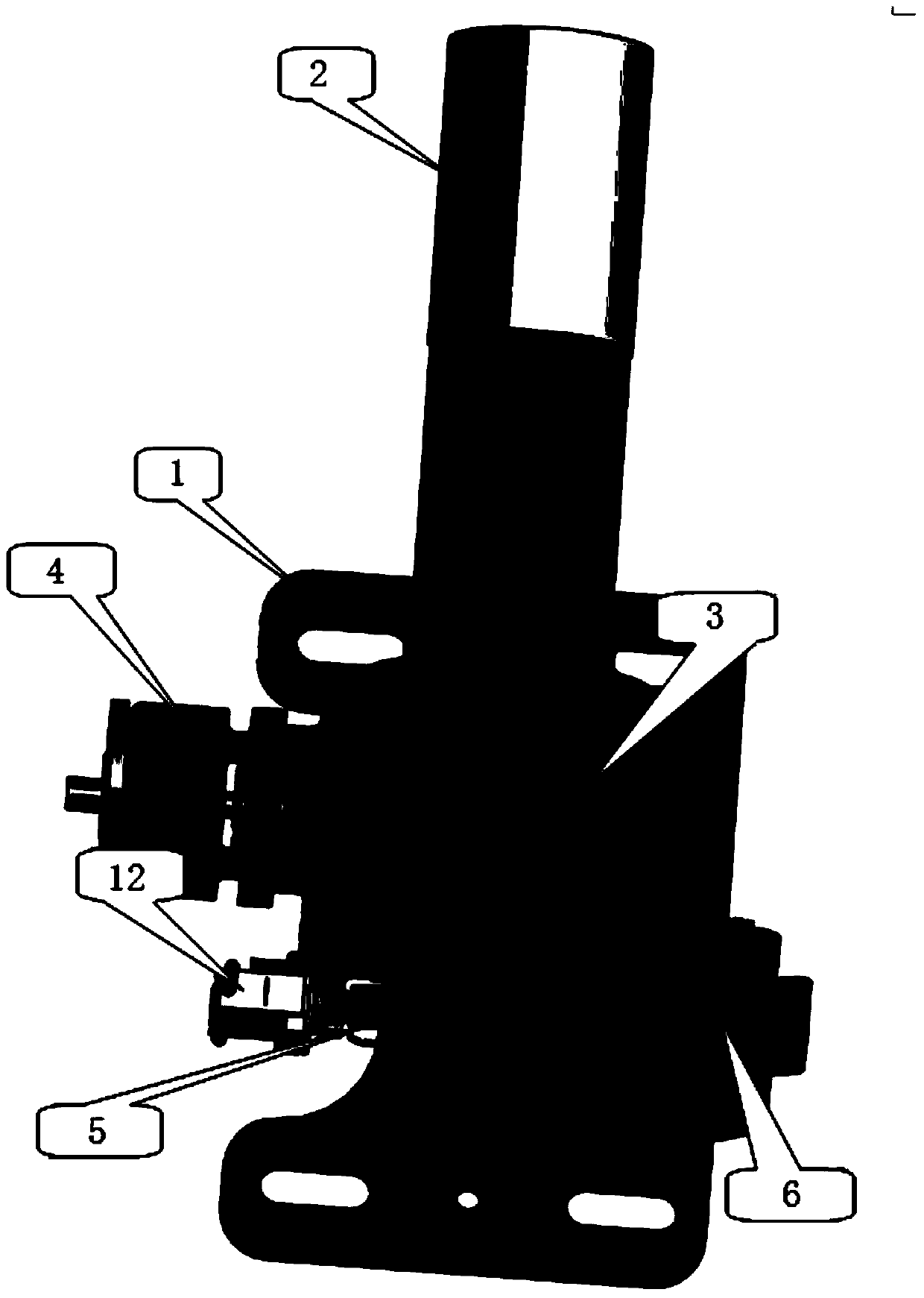

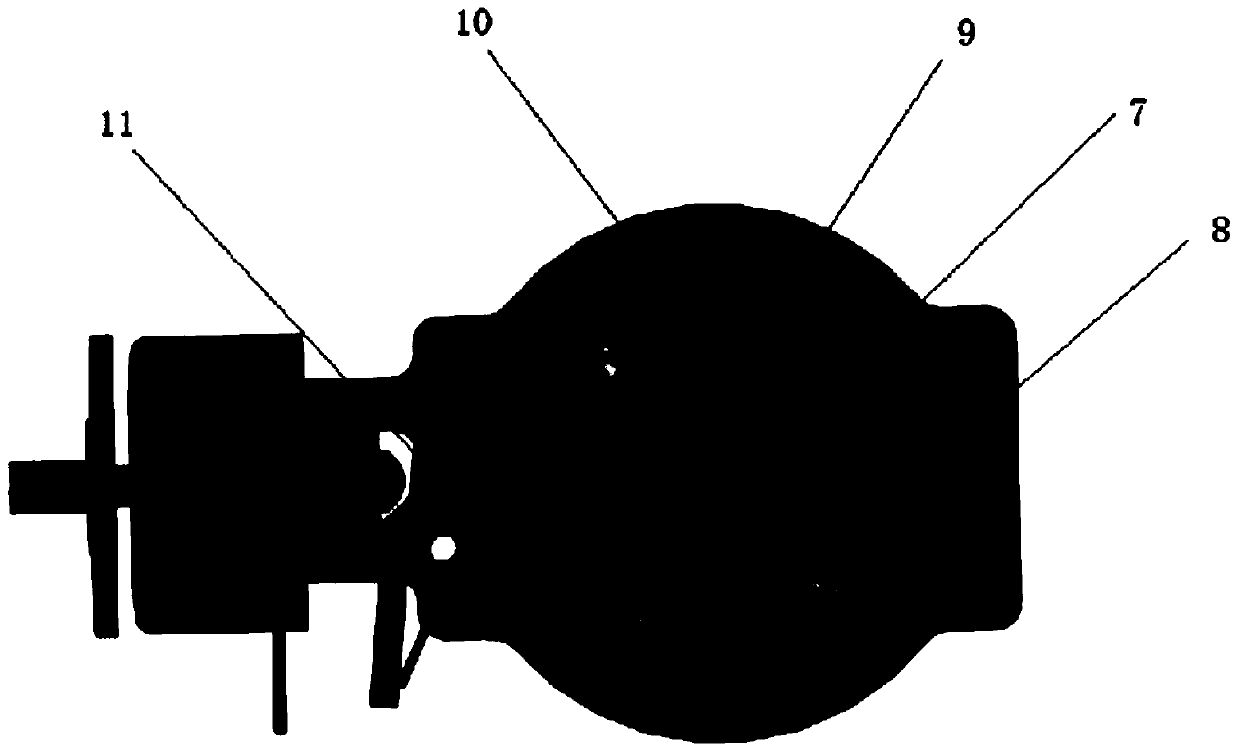

[0016] The invention relates to an electric auxiliary lock for a high-speed rail vehicle electric double-open plug-and-pull door system, which includes a lock body 1, on which a reduction motor 2, a planetary reduction clutch mechanism 3, an inner swing arm 5, and a reduction motor 2 are sequentially arranged. Connect the planetary deceleration clutch mechanism 3, the planetary deceleration clutch mechanism 3 is connected to the inner swing arm 5, and the lock body 1 is also provided with a deadbolt 6, and the deadbolt 6 is arranged on one side of the inner swing arm 5, when the door leaf needs to be locked, The reduction motor 2 reduces the rotating speed through the planetary deceleration clutch mechanism 3, and then drives the inner swing arm 5 to rotate. When the inner swing arm 5 rotates to the lock, the inner swing arm 5 contacts the lock tongue 6 and rotates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com