Roof glass-liner type heat insulating structure of fruiting room for edible fungi

A technology for edible fungi and houses, applied in the application, greenhouse cultivation, roof decoration and other directions, can solve the problems of poor thermal insulation effect, high cost, poor air tightness effect, etc., achieve good air tightness effect, good thermal insulation effect, reduce manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

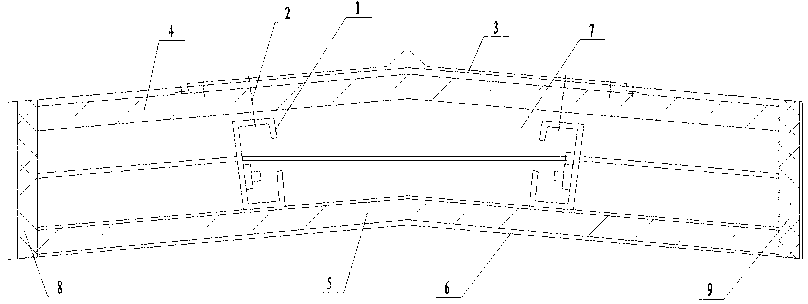

[0009] Such as figure 1 As shown, the roof tank-type insulation structure of the edible fungus fruiting house includes: galvanized purlin 1, a single-layer color steel plate roof 3 set on the galvanized purlin 1 through self-tapping nails 2, and the upper end of the galvanized purlin 1 is set There is an upper thermal insulation cotton 4, a lower thermal insulation cotton 5 is arranged at the lower end of the galvanized purlin 1, a reverse support plate 6 is arranged on the bottom surface of the lower thermal insulation cotton 5, and a bottle liner type is arranged between the upper thermal insulation cotton 4 and the lower thermal insulation cotton 5. Sealing cavity 7, the two ends of bottle liner type sealing cavity 7 are respectively provided with left thermal insulation cotton wallboard 8 and right thermal insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com