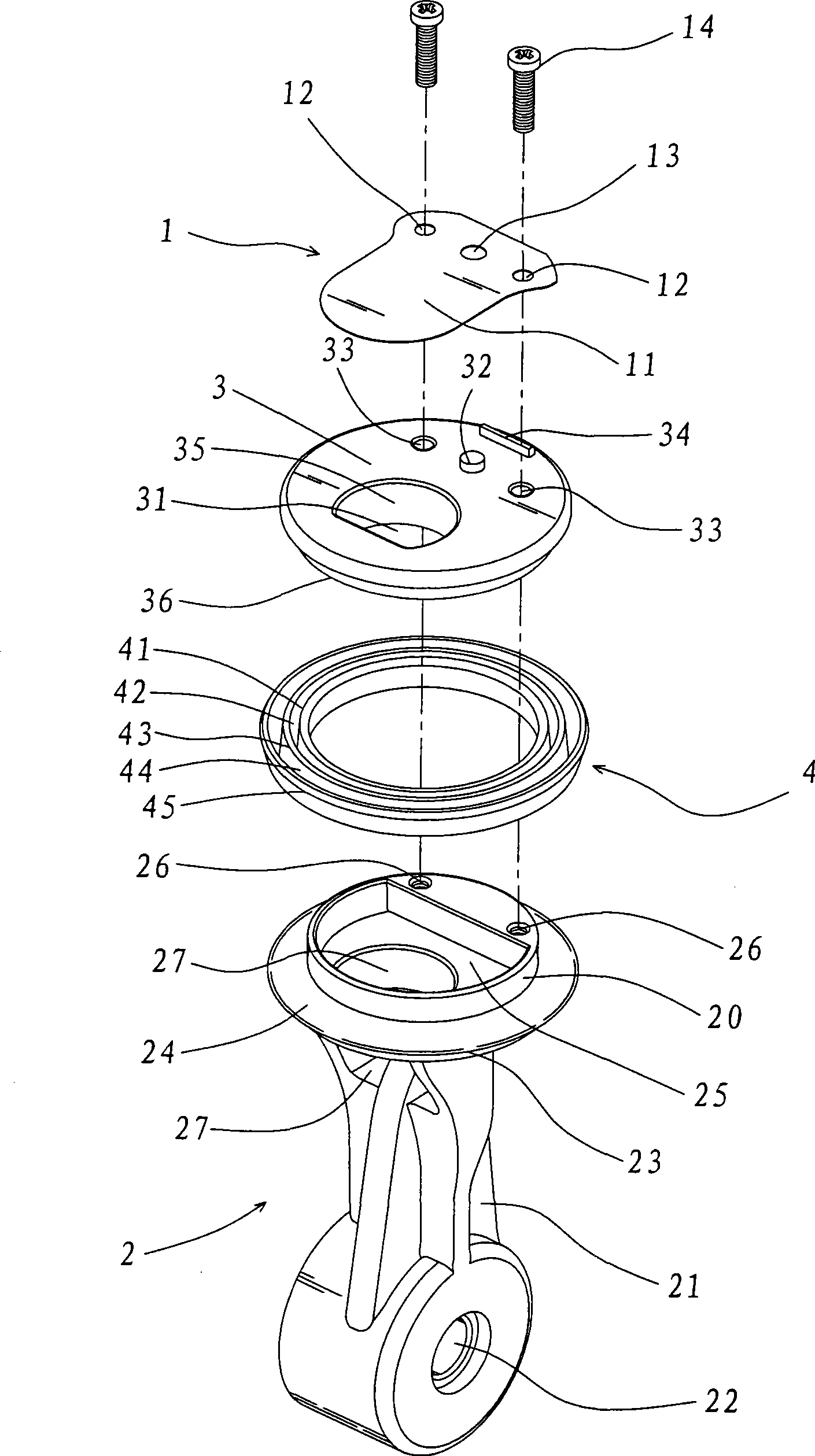

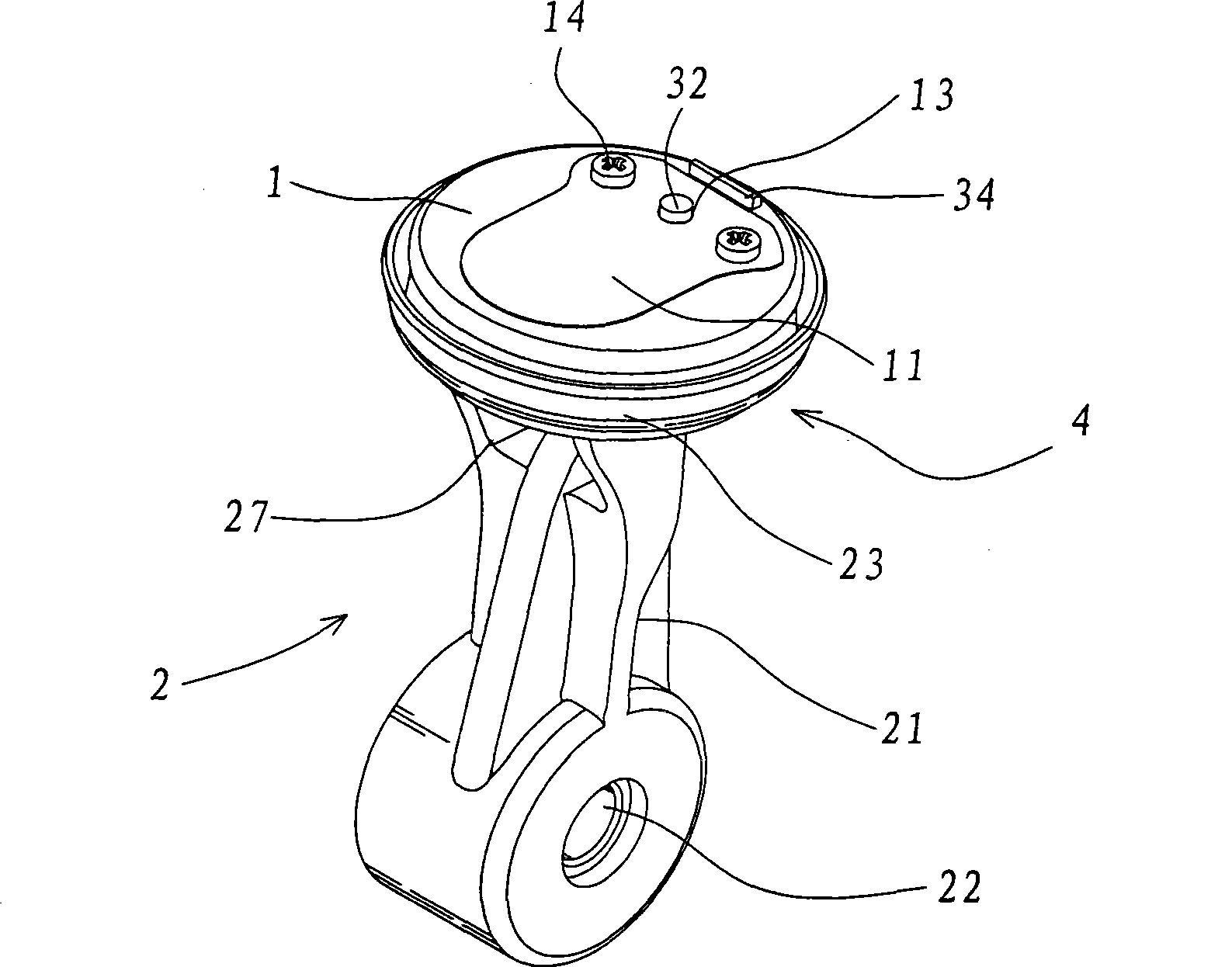

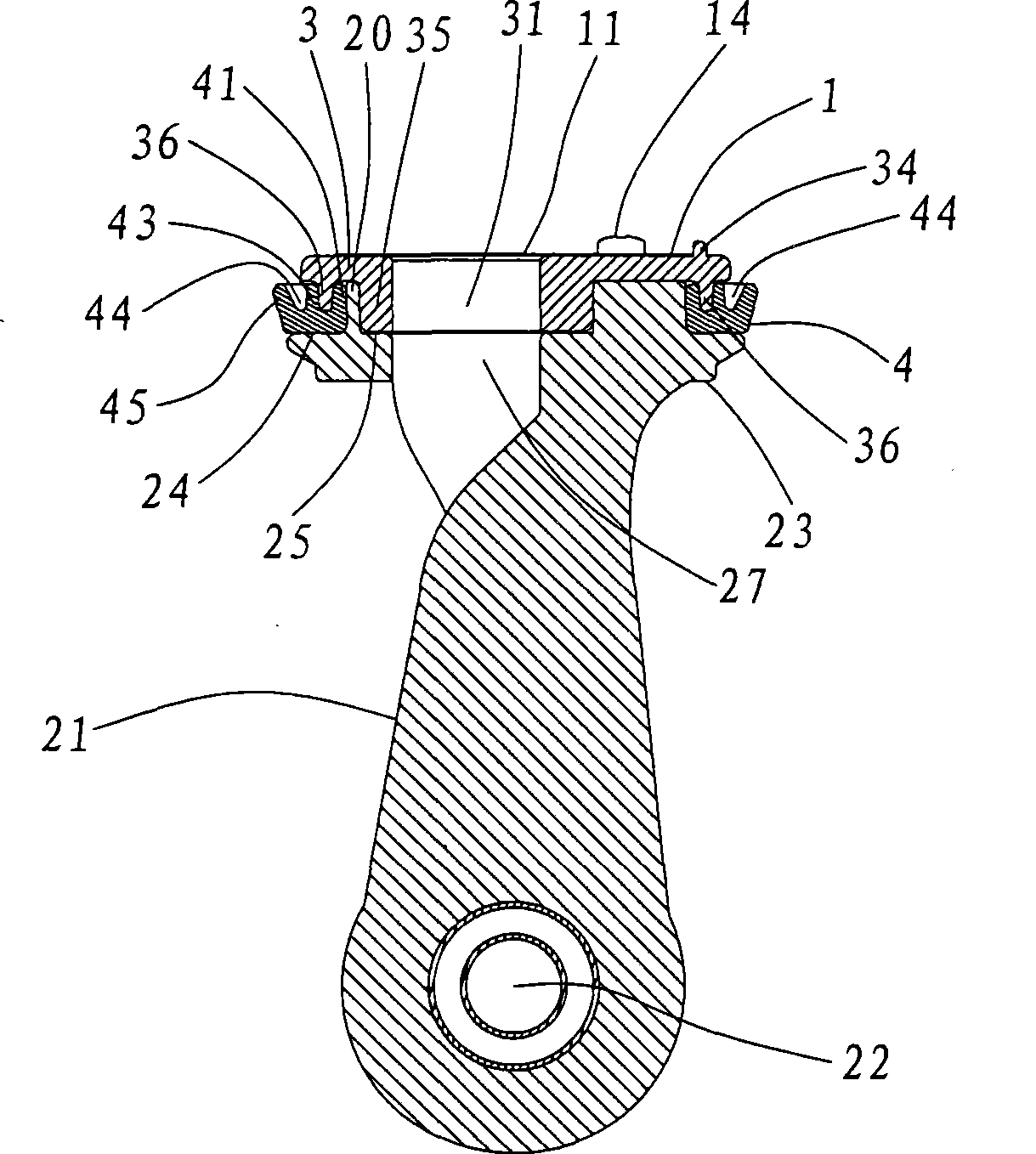

Piston body structure of air compressor

An air compressor and piston body technology, applied in the field of air compressors, can solve the problems of oil seal ring wear, resistance, deformation and bending of the fixed end, etc., and achieve the effect of good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Please refer to Figure 10 to Figure 12 , which is a schematic diagram of an air compressor. A motor 7 is installed behind the base 5. The small gear 71 at the front of the motor 7 is meshed with a large gear 72. The large gear 72 is stacked with a counterweight 74 and combined with a The shaft 73 is pivotally connected to the base 5 , and the counterweight 74 is provided with an eccentric tip 75 pivotally connected to the shaft hole 22 of the piston body 2 . When the motor 7 rotates, the small gear 71 in front of the motor 7 rotates the large gear 72 and the counterweight 74, and the eccentric pin 75 on the counterweight 74 rotates the piston body 2 so that the valve head 23 of the piston body 2 is in the compression cylinder 6 Do repeated movements, so air is transported into the air collection seat 61 and then diverted to the devices installed in the manifolds 62, 63, 64, 65 and flexible pipes 641, 651, such as the barometer 8, the air nozzle 9, the deflated Valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com