Weaving yarn end fast connecting gasbag

A technology of air bag and yarn end, which is applied to spinning machines, textiles and papermaking, and open-end spinning machines, etc. It can solve the problems of not being suitable for high-speed operation of air-jet spinning machines, inconvenient operation, and difficult automation of air-jet spinning. Achieve the effect of convenient and quick installation, good airtight effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

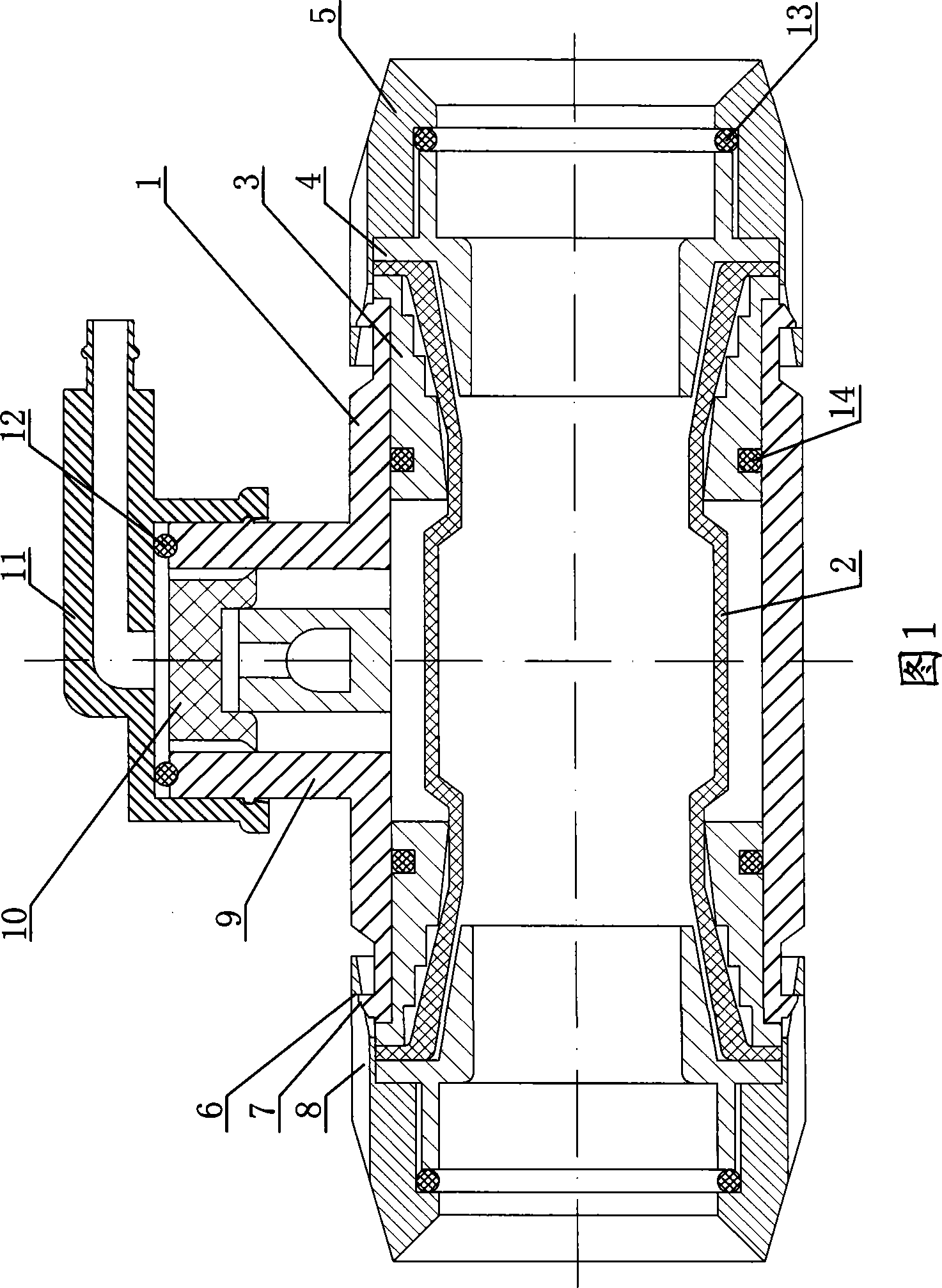

[0009] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] A textile yarn end quick-connect airbag shown in Figure 1, the rubber shrink sleeve 2 is installed in the inner cavity of the tube body 1, and both ends of the tube body are provided with hoops 3 and locking sleeves 4, and the two ends of the rubber shrink sleeve 2 are fixed Installed between the hoop 3 and the locking sleeve 4, and locked by the locking cover 5 at both ends of the pipe body, the locking cover presses the locking sleeve 4, so that the two ends of the rubber shrink sleeve 2 are completely pressed on the hoop 3 and the lock Between the tight sleeves 4; the outer circumference of the nozzle at both ends of the pipe body is evenly provided with a plurality of bosses 7, and the circumference of the cover body of the locking cover 5 is evenly provided with a plurality of locking grooves 8, and the bosses 7 are connected with the locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com