Aluminous shaped tube automobile heat radiator

An automotive radiator, aluminum technology, applied in the direction of machine/engine, engine components, engine cooling, etc., can solve the problems of unsatisfactory effect, increased system cost, high temperature deformation of rubber sealing strip and plastic water chamber, etc. Provides the effect of shortening time, prolonging service life and saving mold investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

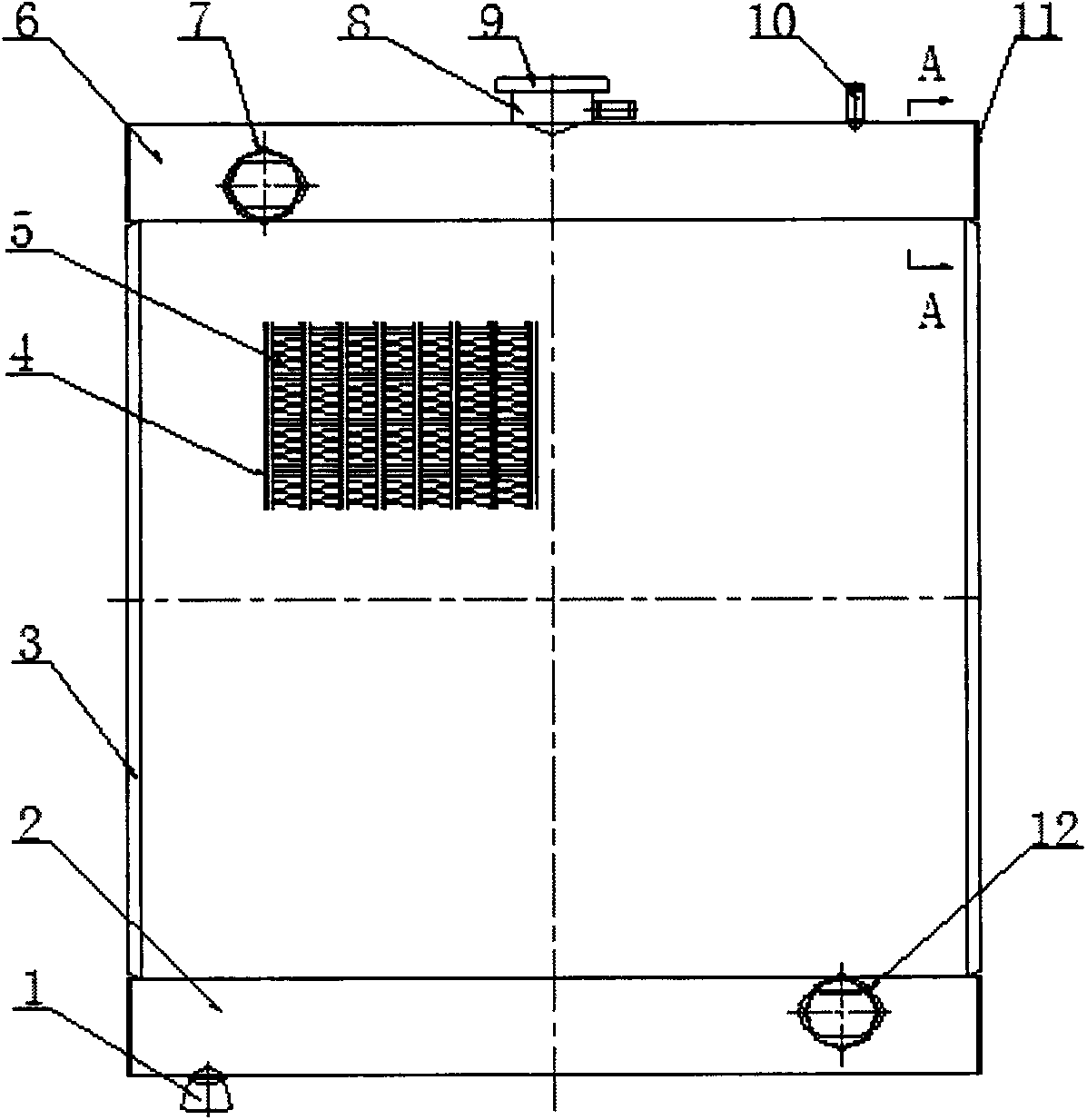

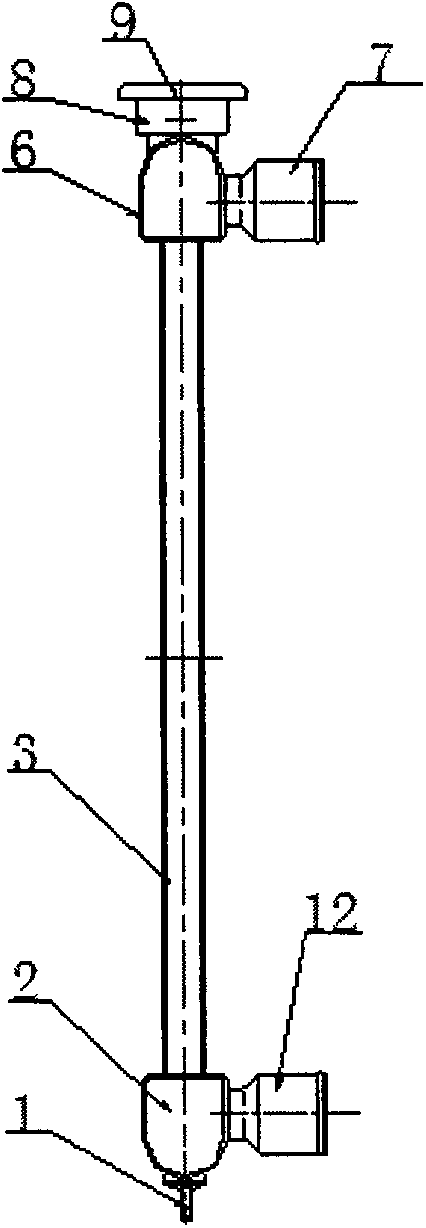

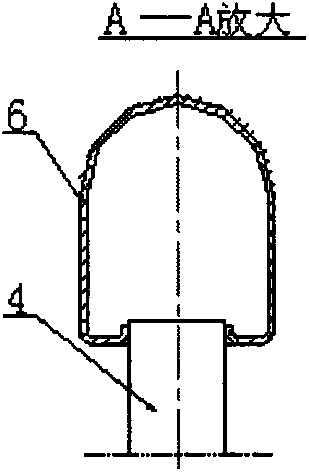

[0034] exist figure 1 , figure 2 , image 3 In the shown embodiment, cooling pipe (4), heat dissipation band (5), side plate (3), water outlet chamber (2), water outlet pipe (12), water discharge valve seat (13), water inlet chamber (6), The water inlet pipe (7), the water inlet (8), the exhaust pipe (10) and the plugging cover (11) are assembled in sequence, and the overall brazing connection is completed once through the nitrogen protection brazing furnace, and the water inlet cover is installed after passing the inspection (9) and drain valve (1).

[0035] exist Figure 8 In the shown embodiment, cooling pipe (4), heat dissipation band (5), side plate (3), water outlet chamber (2), water outlet pipe (12), water discharge valve seat (13), water inlet chamber (6), The water inlet pipe (7), water inlet (8), partition (15), water supply pipe (14), exhaust pipe (10) and plugging cover (11) are assembled in sequence, and the overall brazing is completed once through the nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com