Novel cock valve

A plug valve, a new type of technology, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of complex bottom shell mold design, low production efficiency, high manufacturing cost, etc., achieve compact structure, improve production efficiency, and use in manufacturing The effect of low material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

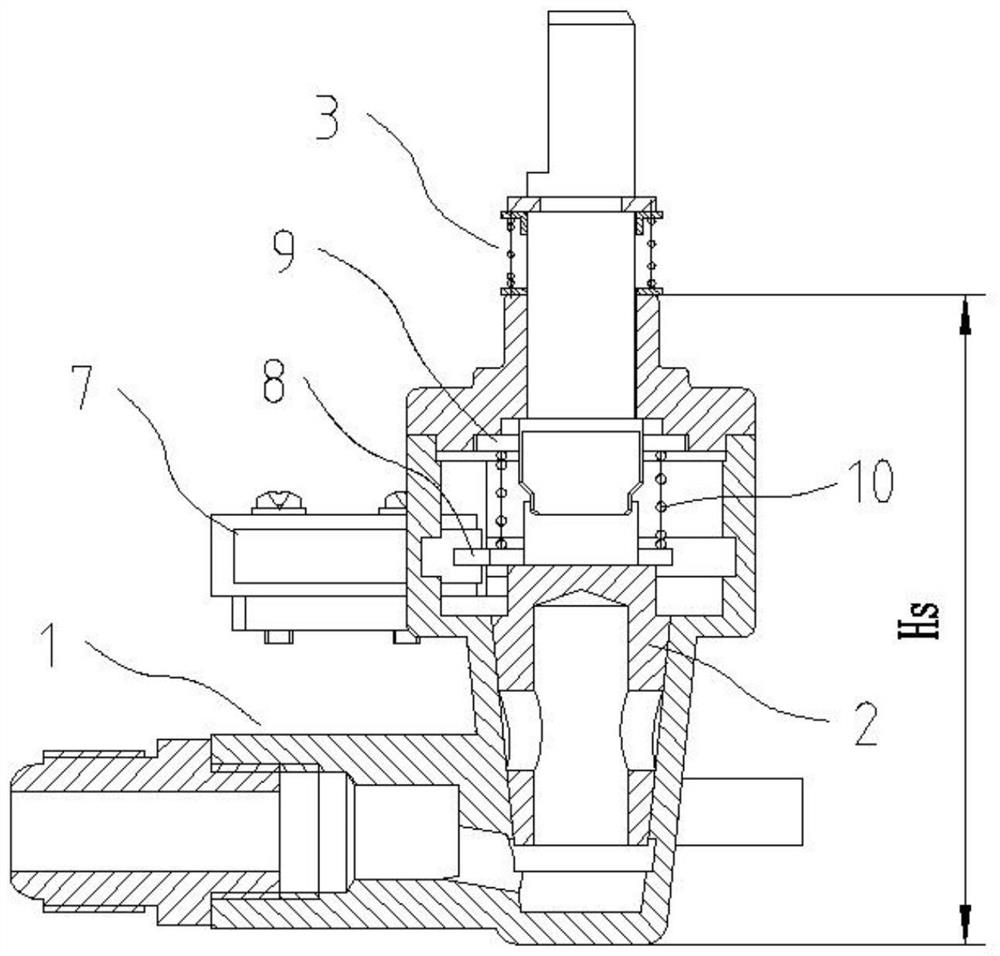

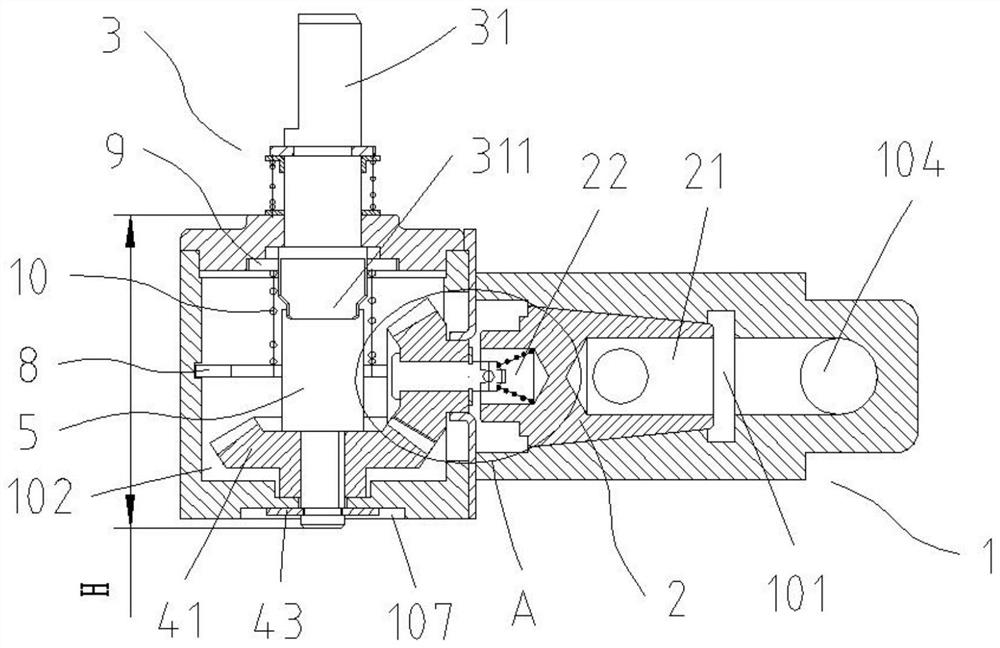

[0027] Such as Figure 2-5 As shown, this embodiment provides a new type of plug valve, including a valve body 1, a valve core 2, a valve stem assembly 3 and a reversing assembly (not shown in the figure), and the valve body 1 is provided with a valve cavity 101 arranged laterally. 1. An accommodating chamber 102 with an upward opening 1021, an air inlet 103 and an air outlet 104. The accommodating chamber 102 communicates with the valve chamber 101 and forms an "L" shape with each other. The valve chamber 101 communicates with the air inlet 103 and the air outlet 104 respectively. The valve core 2 is rotatably disposed in the valve chamber 101 and is provided with an air hole 21 , and the air inlet 103 is selectively connected to the air outlet 104 through the air hole 21 . The stem assembly 3 is rotatably inserted into the accommodating cavity 102 after passing through the opening 1021 . The reversing assembly is rotatably arranged in the accommodating chamber 102, and the ...

Embodiment 2

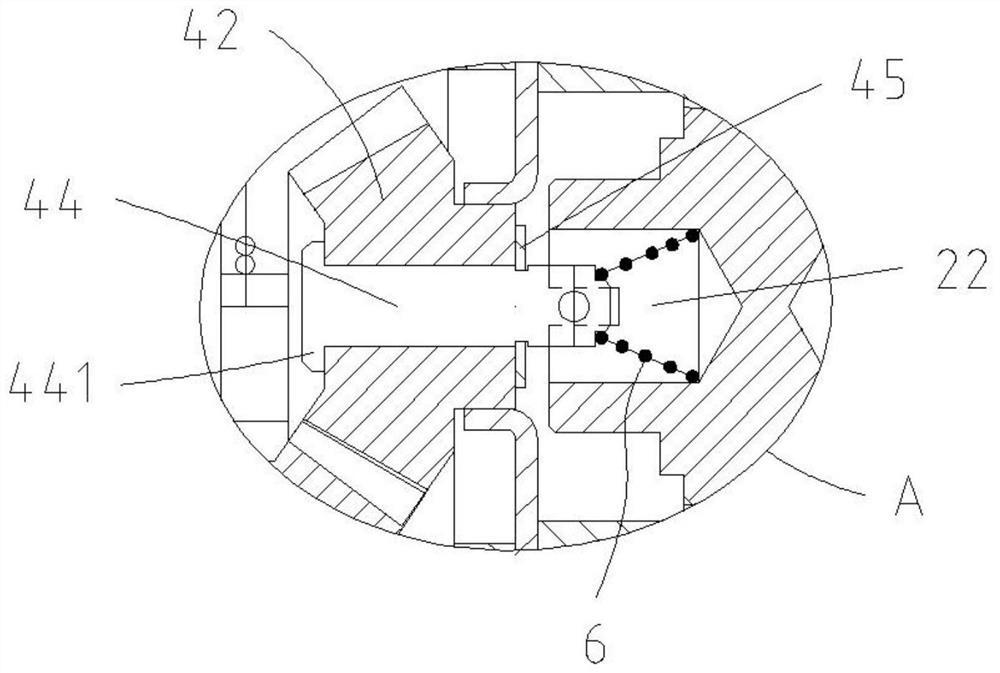

[0049] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the first bevel gear 41 and the second bevel gear 42 are both spiral bevel gears, and the diameter of the end of the second bevel gear 42 meshing with the first bevel gear 41 is much smaller than that of the first bevel gear. The diameter of one end of the bevel tooth 41 engages with the second bevel tooth 42 , and other parts are the same as in the first embodiment.

[0050] It can be seen that by designing both the first bevel gear 41 and the second bevel gear 42 as spiral bevel gears, the gear transmission movement between the first bevel gear 41 and the second bevel gear 42 is more stable, with less noise and a higher load-carrying capacity. Large, it is beneficial to further improve the reliable transmission between the valve body and the valve core, ensure the performance of the new plug valve, reduce the noise generated during use, and improve the user experience. In addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com