Coupled vibration simulation experiment table of aero-engine hydraulic pipeline system

A technology for aero-engine and hydraulic pipelines, which is applied in the testing of fluid pressure actuation systems, mechanical equipment, fluid pressure actuation devices, etc. Fully reflect the vibration of aero-engine hydraulic piping system and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

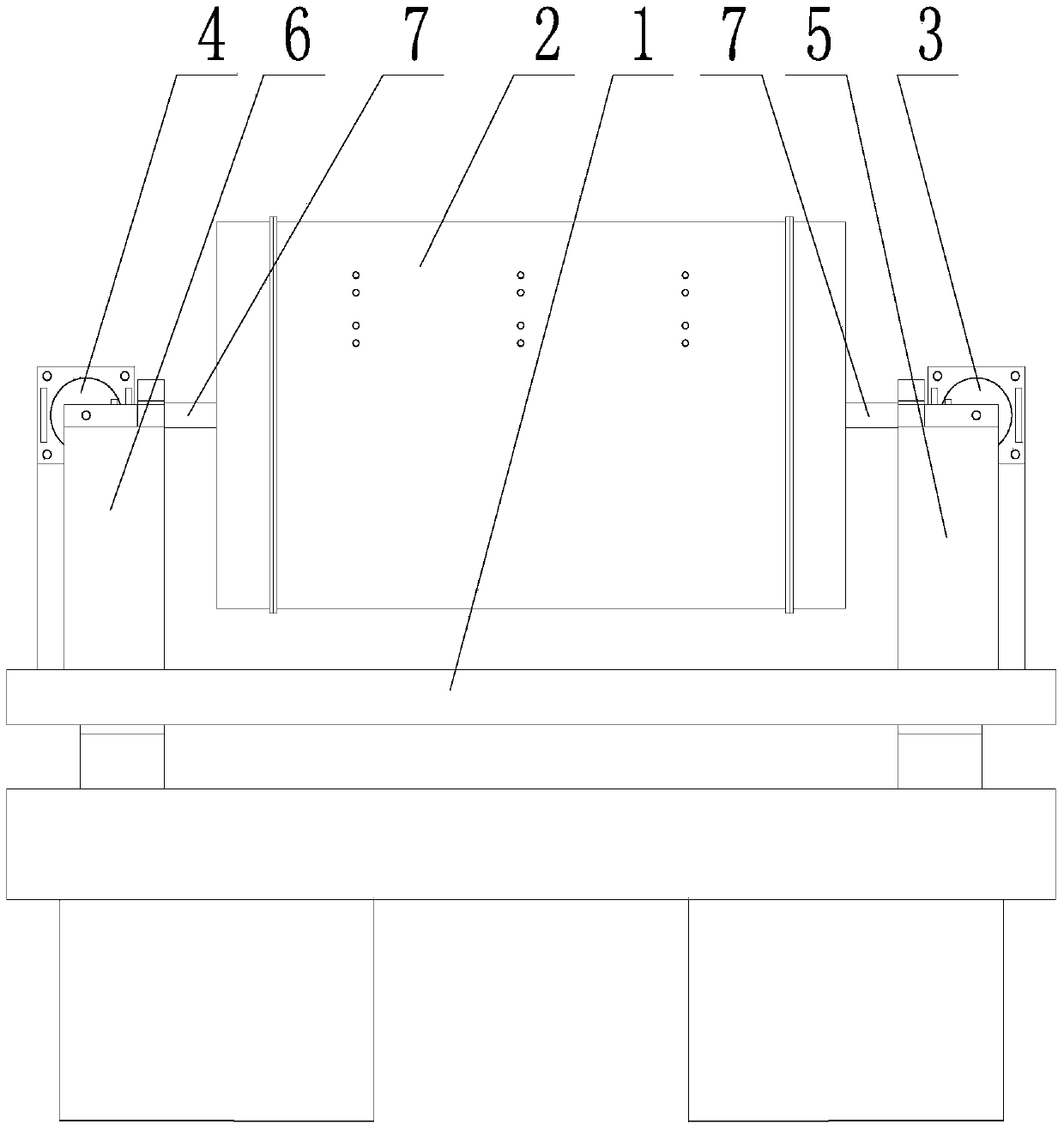

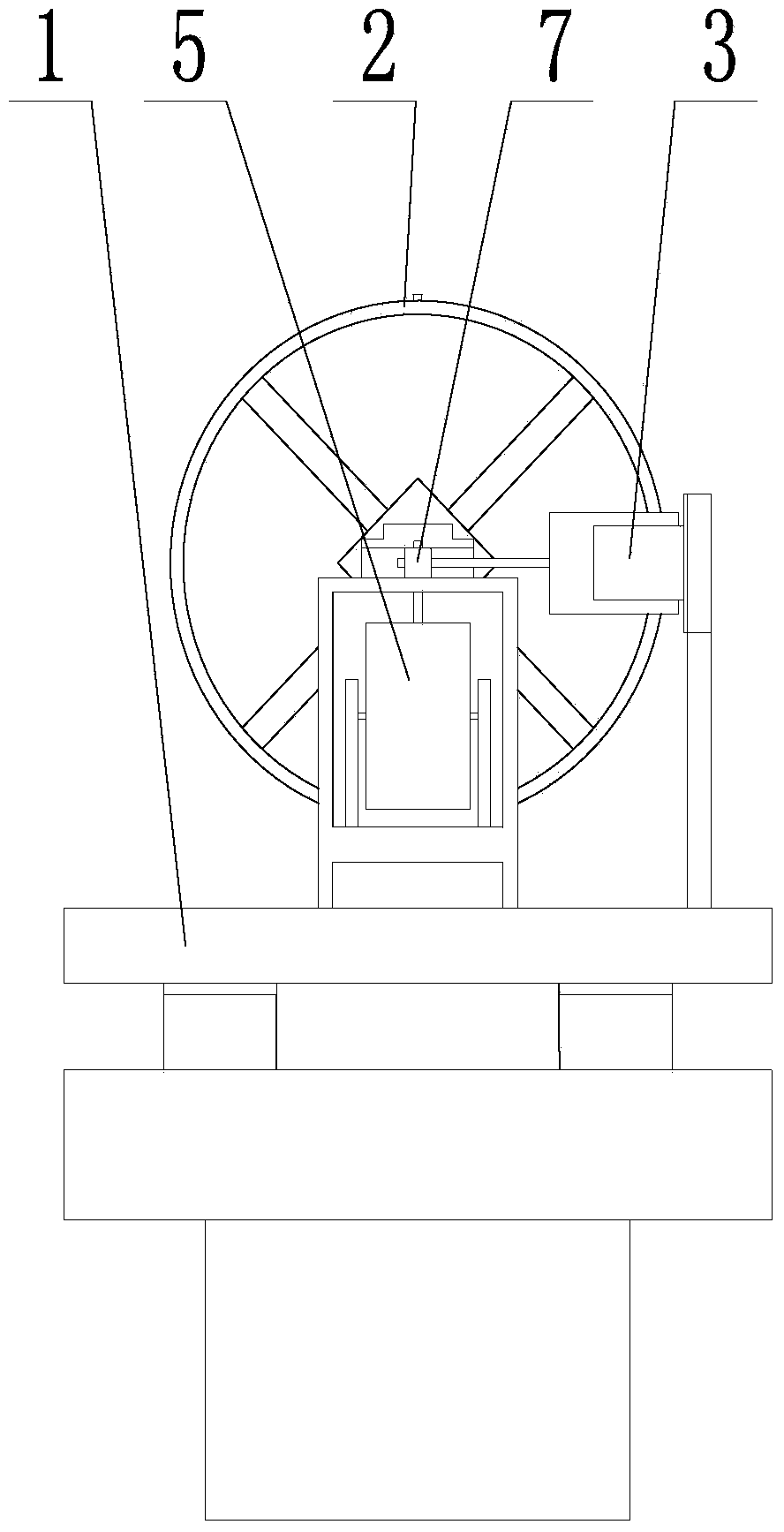

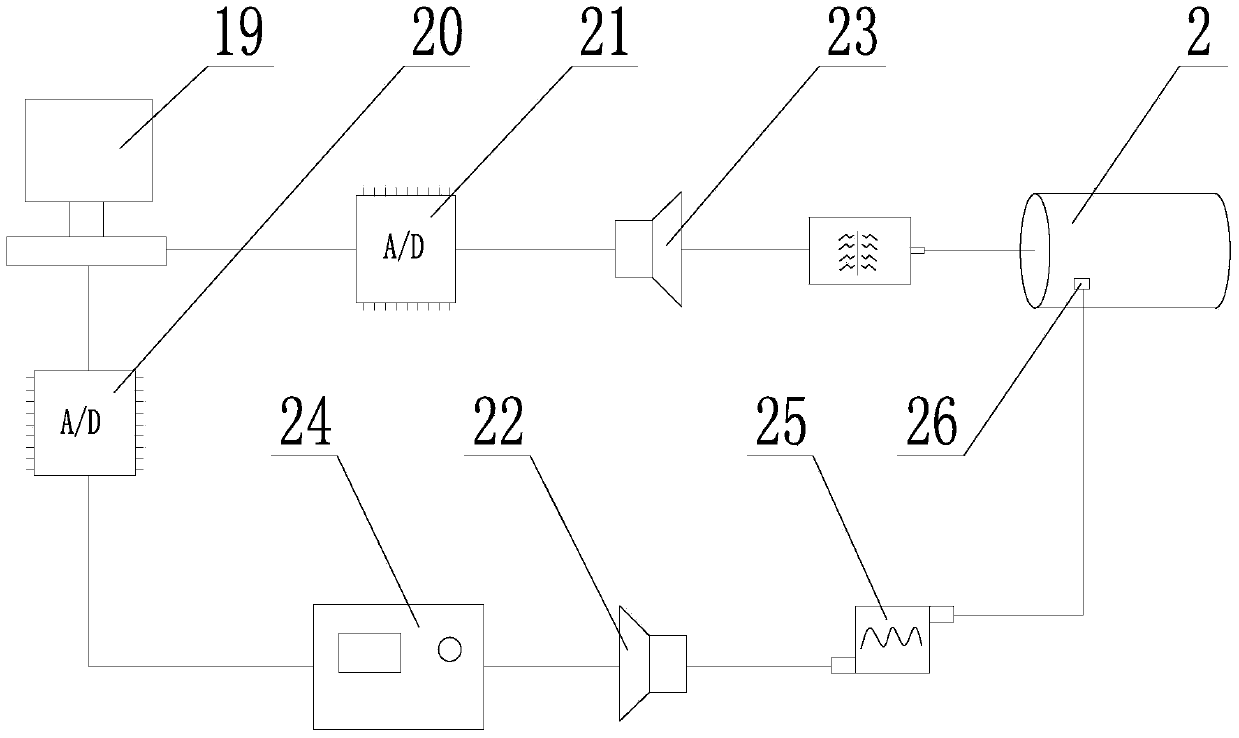

[0022] Such as figure 1 , 2 , Shown in 3 and 4, an aero-engine hydraulic pipeline system coupled vibration simulation test bench, including a pipeline carrier vibration unit, a signal acquisition analysis control unit and a hydraulic pipeline oil supply system unit;

[0023] The pipeline carrier vibration unit includes a base 1, a casing body 2 and an exciter. The casing body 2 adopts a cylindrical structure to simulate an aircraft engine casing, and the casing body 2 is located on the base 1. , several clamps are arranged on the outer cylinder wall of the casing body 2, and the hydraulic pipeline for testing can be fixed on the outer cylinder wall of the casing body 2 through the clamps; a vibration exciter is installed on the base 1, The vibration output end of the vibrator is connected with the casing body 2 through the guide rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com