A non-spicy frying stove premixed hollow burner

A technology for eyes and cooking stoves, applied in the field of stoves, can solve problems such as hot eyes or pungent nose, loud noise, and high energy consumption, and achieve the effect of strong firepower, sufficient combustion, and avoiding wind blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

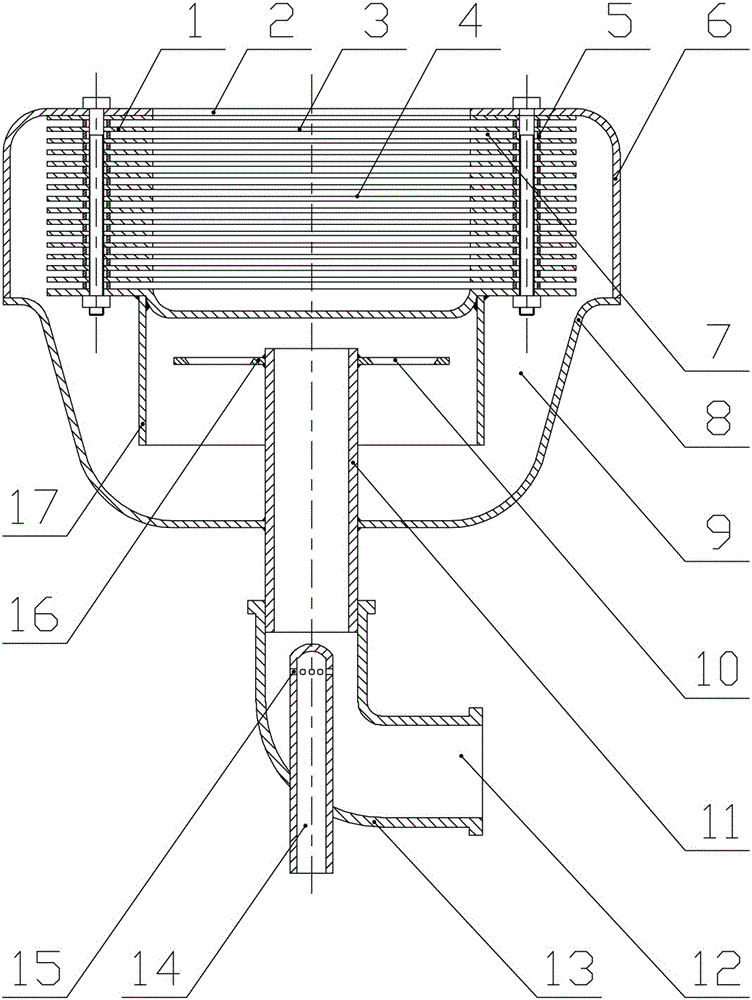

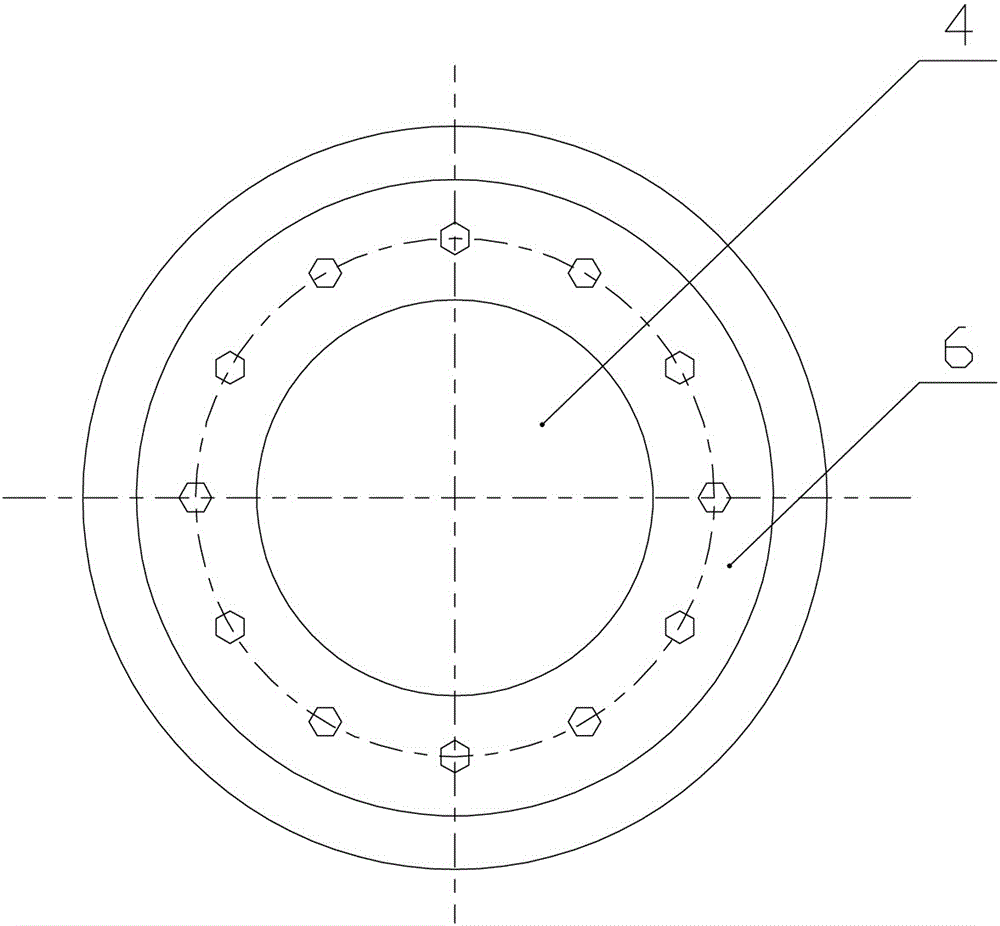

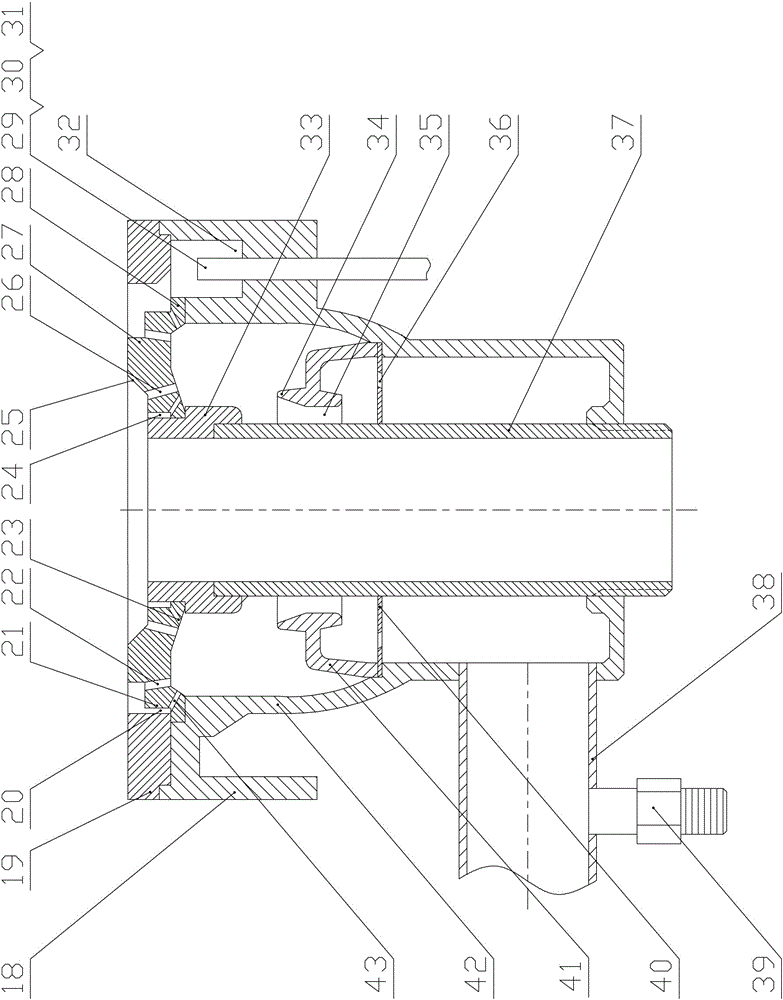

[0024] Various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The first embodiment of the present invention is mainly used as a burner of a steam engine. see image 3 and Figure 4 , the burner has a furnace shell 42, the lower side wall of the furnace shell 42 is equipped with an air inlet pipe 38, and the air inlet pipe 38 is equipped with a gas inlet pipe 39. A furnace plate 25 is installed in the middle of the top of the furnace shell 42, and a circle of outer main fire holes 22 is opened on the furnace plate 25, and an upper cover 19 that presses the furnace plate 25 is installed on the top edge of the furnace shell 42; especially: the furnace plate 25 is designed as an upper, middle and lower three-layer ladder structure, and the diameters of upper strata 27, middle strata 21 and lower strata 28 increase sequentially from top to bottom, and loam cake 19 is pressed on the top of the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com