A garbage purification furnace

A technology for purifying furnaces and garbage, applied to incinerators, combustion methods, combustion types, etc., can solve the problems of high investment costs, complex structures, etc., and achieve the effects of low material consumption, simple structure, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

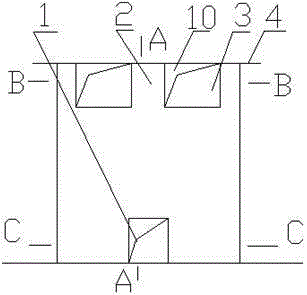

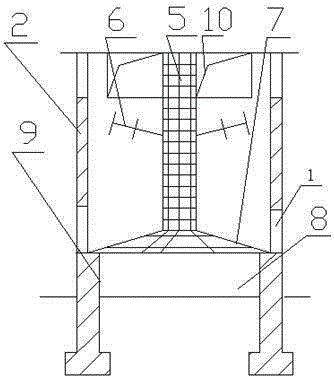

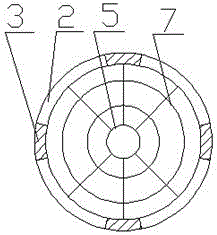

[0022] Embodiment 1, the cage (5) is made of steel bars, the bottom of the cage (5) is the base furnace bridge (7), and the furnace bridge ( 6), the top of the cage body (5) is the top grid (4), the bottom of the base furnace bridge (7) is fixed on the feet (9), the feet (9) are at the bottom of the inner cavity of the furnace body (2), and the furnace body ( 2) The outer diameter is circular, the inner cavity is larger at the bottom and smaller at the top, and the larger bottom is used to support the base furnace bridge (7). The cage body (5) is cylindrical, and the base furnace bridge (7) is conical. The sub-stove bridge (6) is a supporting shape, with a steel bar as the main pole, 2 to 3 cross-arms are welded on the main pole, welded at the same height as the outer diameter of the cage (5), installed in a misplaced position or in a square shape , like the distribution of branches on the tree trunk. The furnace body (2) is closed around the circumference and up and down, b...

Embodiment 2

[0023] Embodiment 2, according to the structure of embodiment 1 is substantially unchanged, but a structure similar to the base furnace bridge (7) with a taper is installed in the middle of the cage body (5), which is the second layer of base furnace bridge (7). In this way, there are gaps in the garbage heap during the garbage incineration process, which is conducive to sufficient combustion and the effect is also good.

Embodiment 3

[0024] In embodiment 3, the structure according to embodiment 1 is basically unchanged, but more than one bar-shaped tubular shape is vertically installed on the ring edge of the base furnace bridge (7). Combusting the garbage branches separately can also achieve the desired effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com