Smoke dust reheating waste incineration boiler all-in-one machine

A technology of waste incineration and integrated machine, which is applied to incinerators, steam generation methods using heat carriers, combustion methods, etc. The effect of reducing the amount of smoke and dust, suitable for large-scale promotion and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

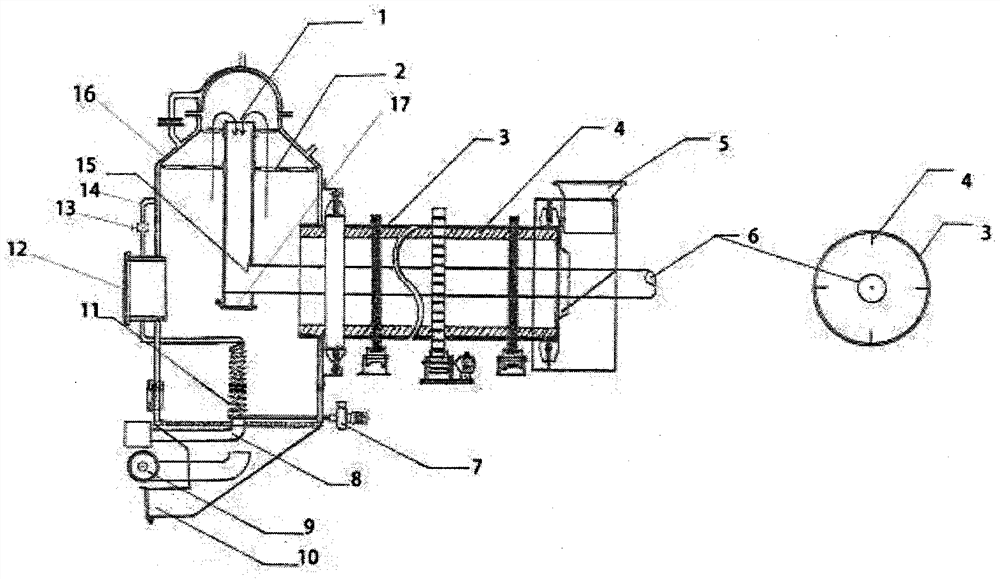

[0022] figure 1 It is a perspective view of a smoke and dust reheating waste incineration boiler integrated machine of the present invention, which constitutes an embodiment of the present invention: this solution consists of a double-layer waste incineration boiler 16, a hot smoke and dust pipeline return inlet 1, and a hot smoke and dust pipeline in the double-layer waste incineration boiler 16 The center is directly down to the central position, and then extends horizontally to the drying roller kiln 3 at an angle of 90 degrees, and is in a horizontal state with the drying roller kiln until it passes through the drying tunnel kiln to the garbage inlet 5 direction, hot smoke and dust The pipeline is provided with a coarse ash baffle 15 at the upper end of the 90-degree corner in the double-layer garbage incineration boiler 16, and a cleaning valve 17 is provided at the lower end of the 90-degree corner, and a drying roller kiln 3 is provided around the hot smoke and dust pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com