A liquid header

A header and liquid separation technology, applied in separation methods, dispersed particle separation, lighting and heating equipment, etc., can solve the problems of reduced gas-liquid separation efficiency, inconsistent fluctuation range, inconsistent liquid flow rate, etc., to reduce liquid volume, The effect of increasing manufacturing cost and suppressing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

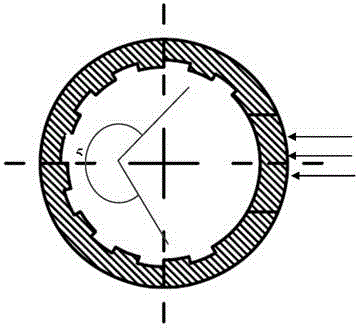

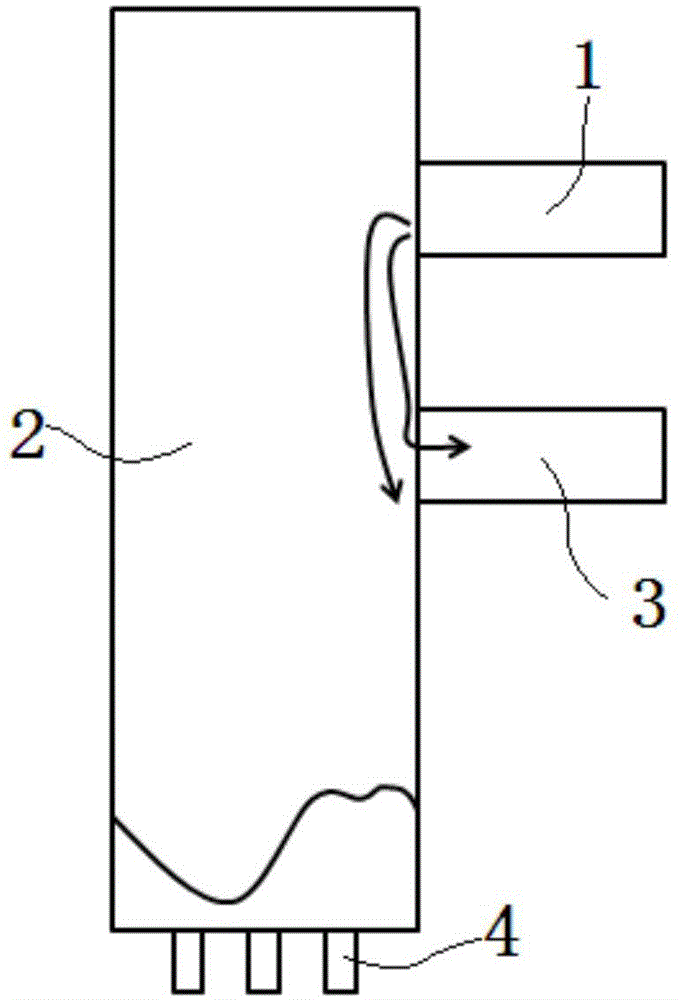

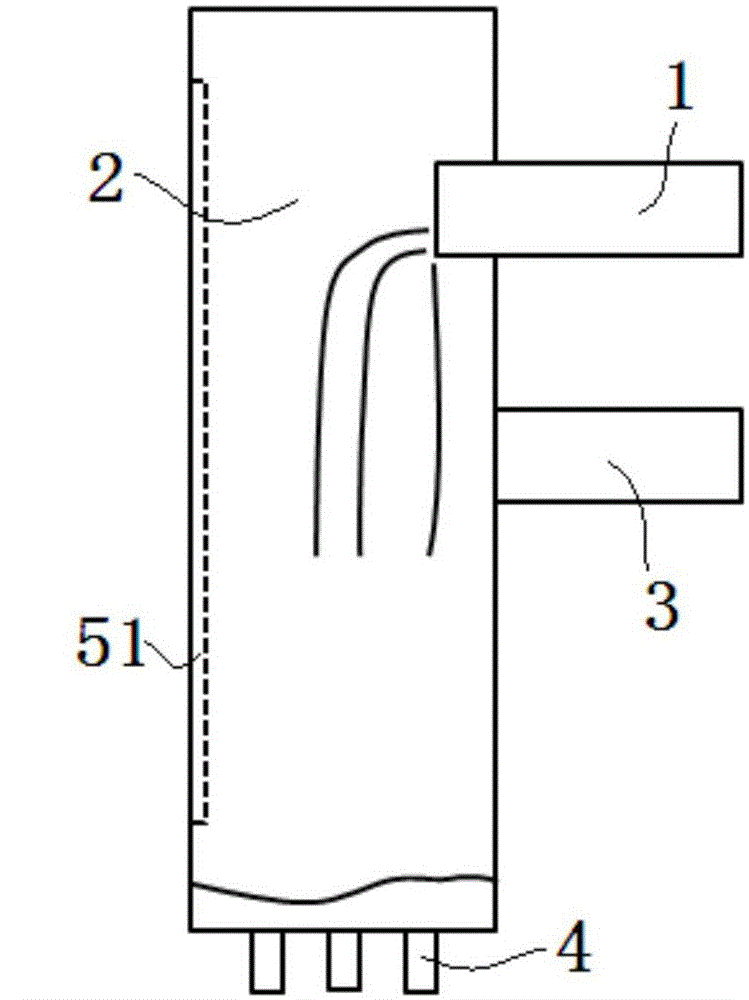

[0025] A liquid header, such as figure 2 As shown, it consists of an incoming branch pipe 1, a header 2, an outflow branch pipe 3 and a drain core 4. The inflow branch pipe 1 and the outflow branch pipe 3 are round pipes arranged horizontally, the header 2 is a round pipe arranged vertically, and the inner diameter of the header 2 is about 2 to 4 times the inner diameter of the inflow branch pipe 1, This is the best way to dispense liquid. Preferably, the inner diameter of the header 2 is 12.5-25 mm. The inflow branch pipe and the outflow branch pipe are installed on the outer wall of the header and communicate with the inner chamber of the header. The incoming branch pipe 1 is installed on the outer wall of the header 2 , and one end of the incoming branch pipe 1 is inserted into the side wall of the header 2 and protrudes a little from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com