Comb-teeth Cylindrical Capacitive Sensor Based on Mutual Capacitance Measuring Principle

A capacitive sensor and measurement principle technology, which is applied in the direction of measuring devices, instruments, and electric devices, can solve problems such as low signal-to-noise ratio, high requirements for the use environment, and sensitive surface roughness to be measured, and achieve a wide range of applications and simplified The effect of configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

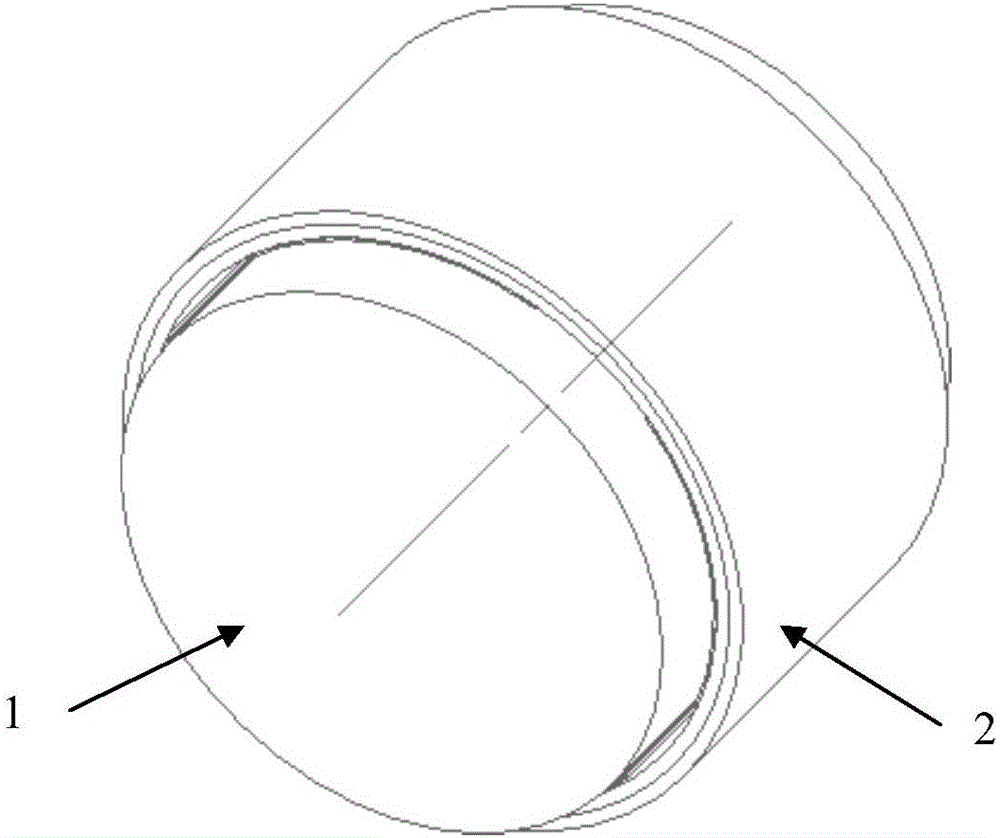

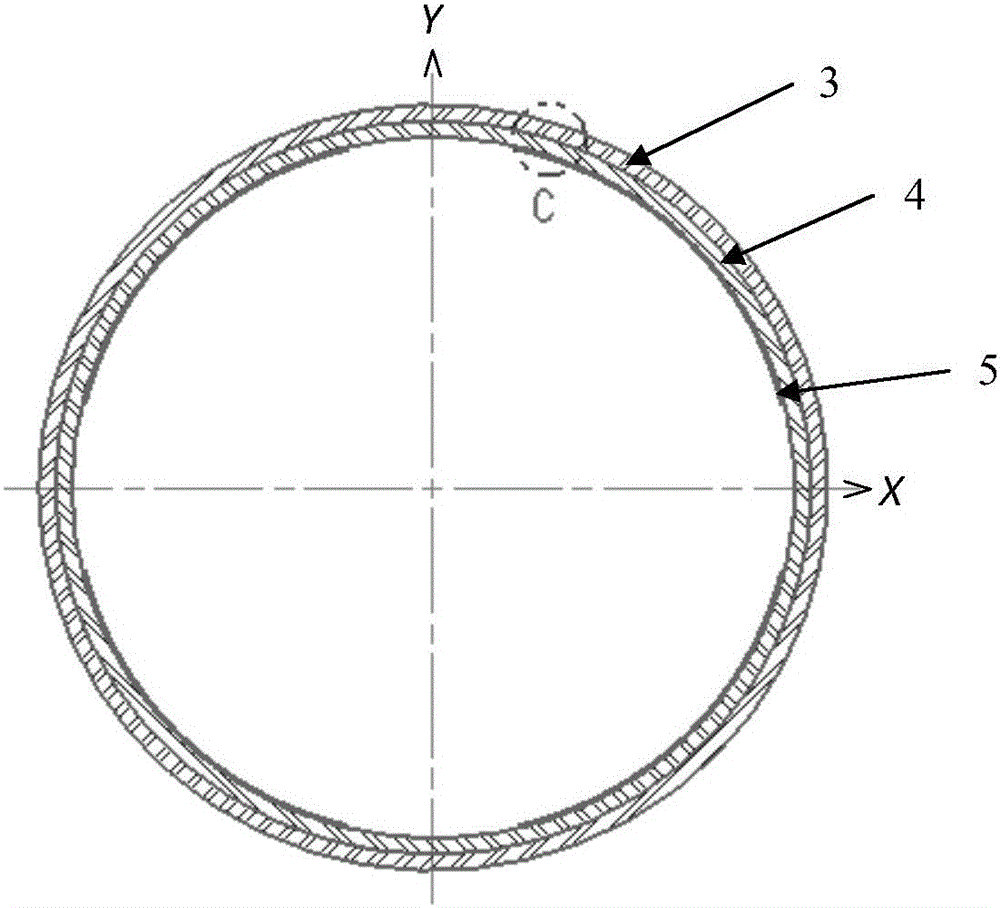

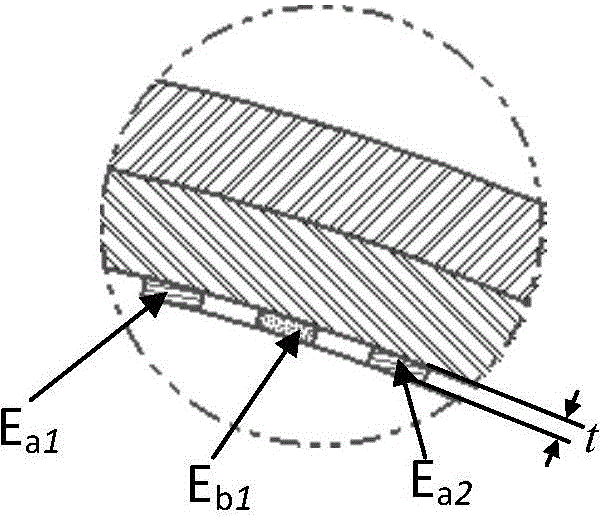

[0024] Such as figure 1 , figure 2 As shown, during the measurement, the sensor 2 is coaxially installed outside the measured rotor 1 as a stator, and the inner circular surfaces of the four sets of mutual capacitance measurement units maintain the same radial distance from the measured rotor; the structure of the sensor 2 is sequentially composed from outside to inside It is a sensor housing 3, an insulating matrix layer 4, and four sets of mutual capacitance measuring units 5 with the same structure. The three are coaxially arranged and have the same axial length. The axial length of the mutual capacitance measuring unit is L; the cylinder located in the insulating matrix layer 4 The four groups of mutual capacitance measuring units 5 on the surface are distributed in four quadrants in turn and are symmetrical to each other along the X and Y axes. The circumferentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com