Special flower basket for optical element etching

A technology of optical components and components, applied in the preparation of test samples, etc., can solve the problems of scratches and damages of optical components, inconsistent etching time of optical components, etc., and achieve easy operation, improved experimental efficiency and precision, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

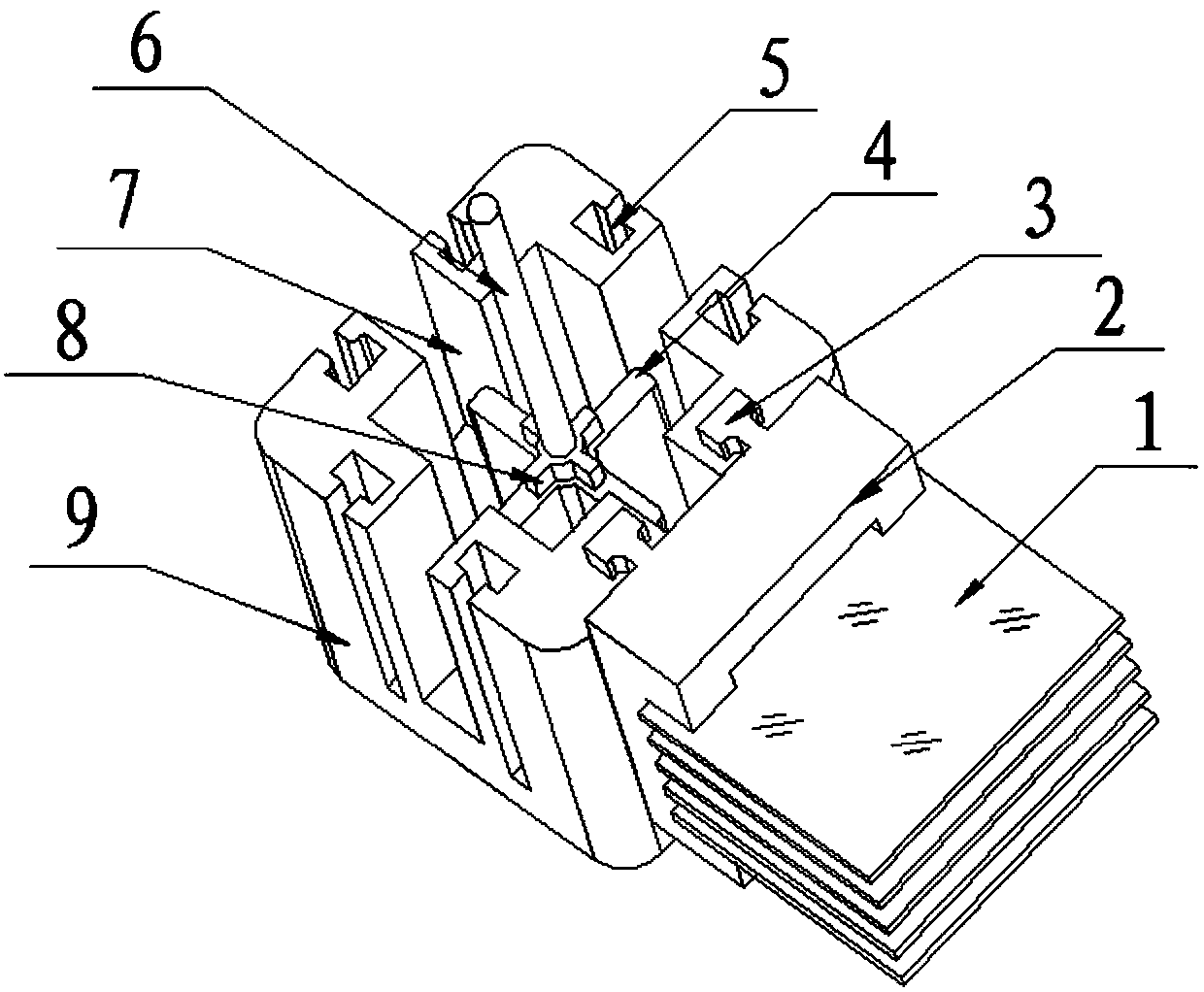

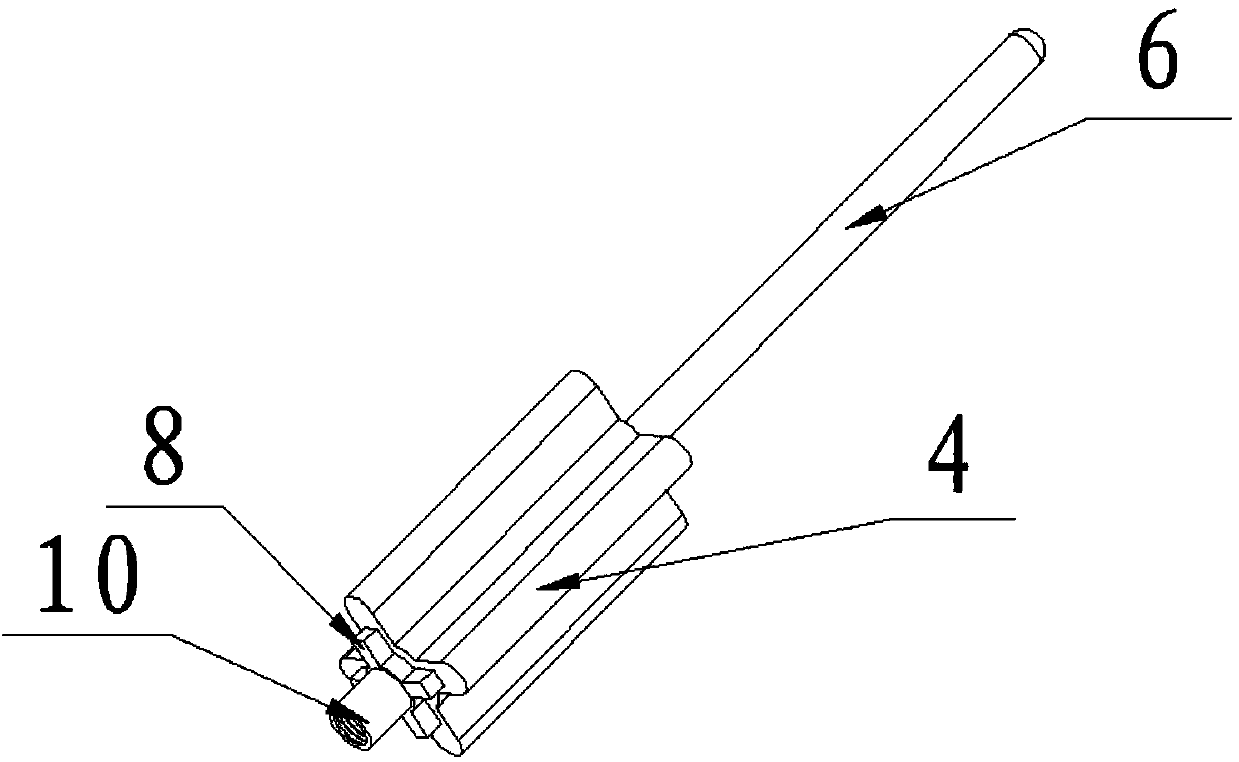

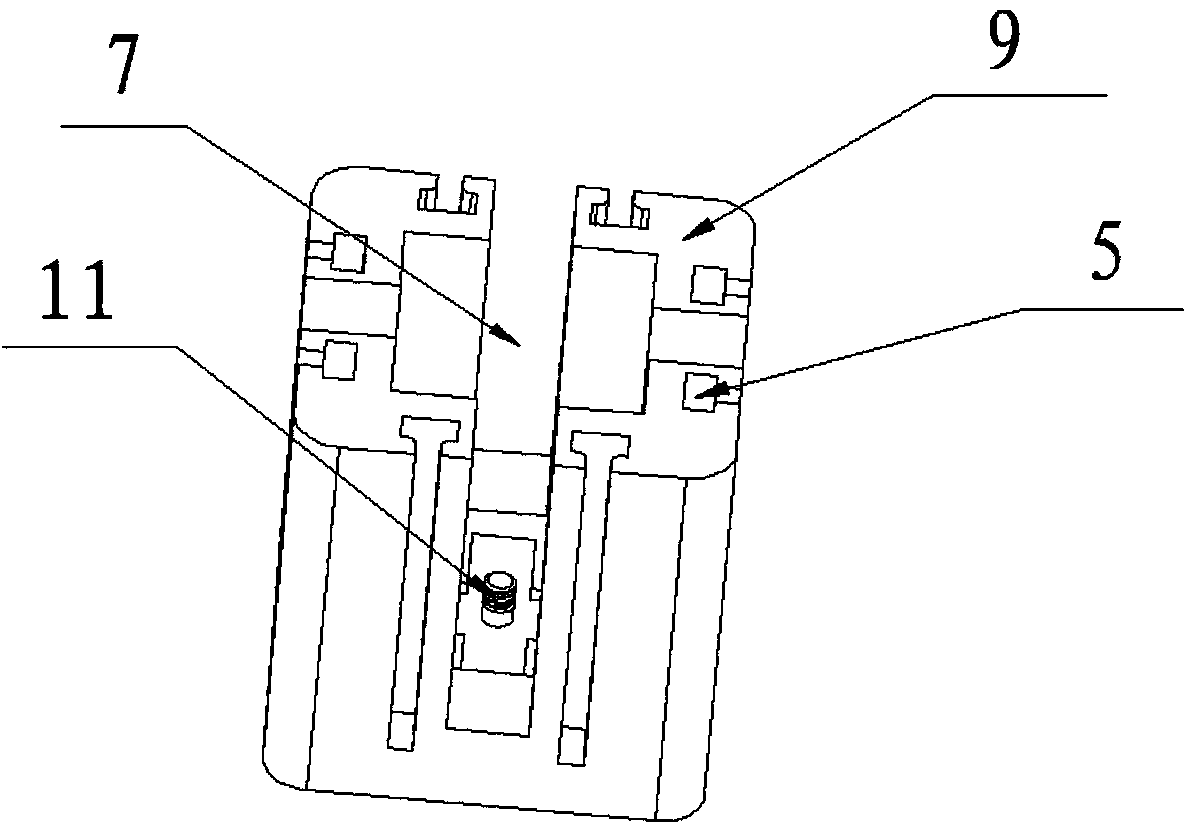

[0019] Such as Figure 1-7 As shown, the embodiment of the present invention is provided with a plug-in component rack 2 , a component rack base 9 , and a handle 6 . The component holder base 9 is provided with a T-shaped mounting groove 5, a through groove 7, and a handle installation shaft 11; the plug-in component holder 2 is provided with a component groove 12, a rubber protection pad 13, a T-shaped mounting foot 3, and a penetrating Slot 14; the handle is provided with a micro motor 8, a stirring blade 4, a handle installation groove 10, and the handle installation groove 10 and the handle installation shaft 11 are all provided with threads.

[0020] The plug-in component rack is provided with several component slots 12, and the upper and lower sides of the component slot 12 are respectively provided with several triangular rubber protection pads 13; the plug-in component rack 2 can be customized according to the size of the optical component 1. Plug-in component racks o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com