Etching solution for copper/ molybdenum (niobium)/ indium gallium zinc oxide (IGZO) film, as well as preparation method and application thereof

A technology of etching solution and film layer, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high price and affecting the profit level of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

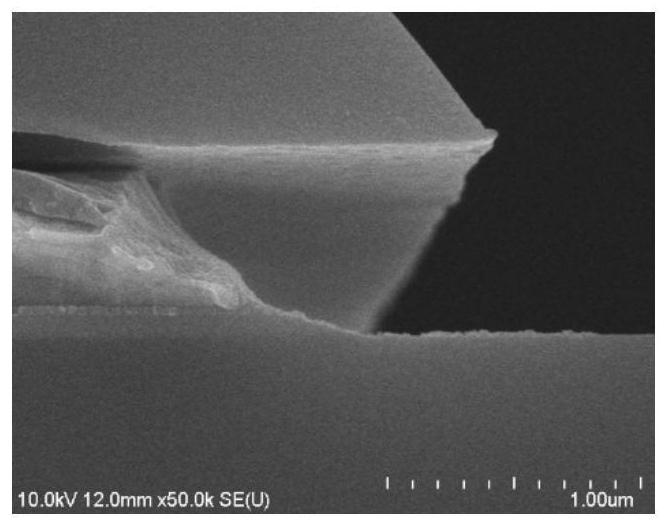

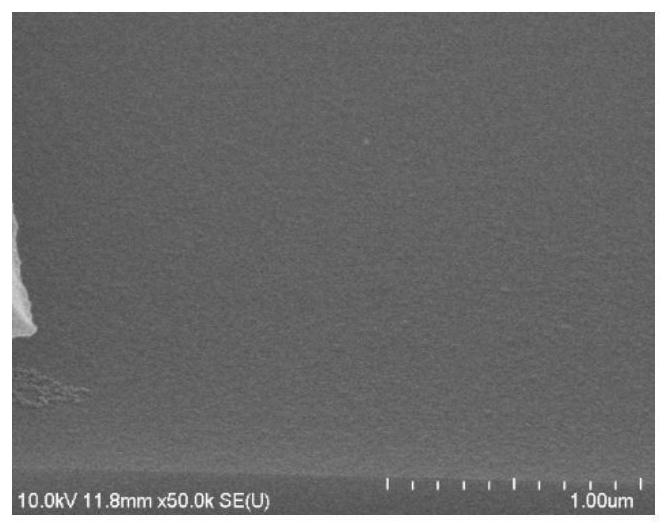

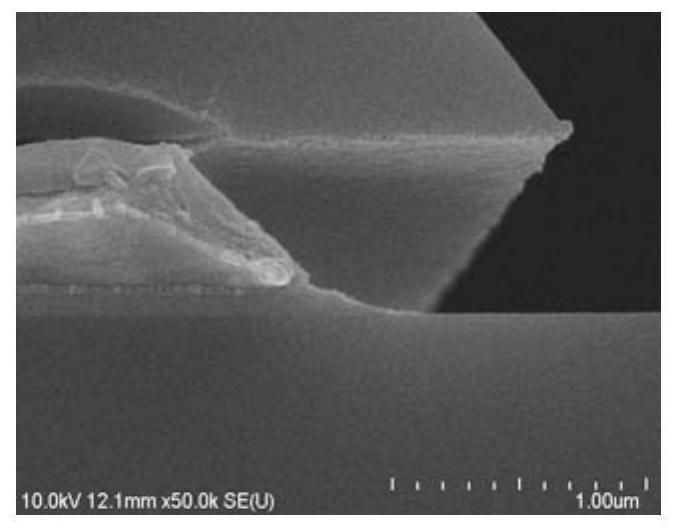

Image

Examples

Embodiment 1

[0085] The etching solution A agent (that is, the main agent, the same below) for the copper / molybdenum (niobium) / IGZO film layer in this embodiment includes the following components according to the mass percentage:

[0086]

[0087]The above-mentioned nitric acid and water were mixed and stirred, and then hydrofluoric acid, tetramethylammonium hydroxide, phenylurea, 9-aminocarbazole and hydrogen peroxide were sequentially added to the mixed system and stirred. It can be used after being filtered by 0.5μm and 0.2μm filter elements in turn. The pH of the A agent was 3.1.

[0088] During the whole preparation process, the temperature of the etching solution A agent system was maintained below 45°C.

[0089] The etching solution B agent (that is, the additive, the same below) used for the copper / molybdenum (niobium) / IGZO film layer in this embodiment includes the following components according to the mass percentage:

[0090]

[0091] The above nitric acid and water were...

Embodiment 2

[0094] The etching solution A for the copper / molybdenum (niobium) / IGZO film layer of this embodiment includes the following components according to the mass percentage:

[0095]

[0096] The above-mentioned nitric acid and water were mixed and stirred, and then ammonium fluoride, tetramethylammonium hydroxide, phenylurea, 3,9-diaminocarbazole and hydrogen peroxide were sequentially added to the mixed system and stirred. It can be used after being filtered by 0.5μm and 0.2μm filter elements in turn. The pH of the A agent was 3.1.

[0097] During the whole preparation process, the temperature of the etching solution A agent system was maintained below 45°C.

[0098] The etching solution B agent for the copper / molybdenum (niobium) / IGZO film layer of this embodiment includes the following components according to the mass percentage:

[0099]

[0100] The above-mentioned nitric acid and water were mixed and stirred, and then ammonium fluoride, tetramethylammonium hydroxide ...

Embodiment 3

[0103] The etching solution A for the copper / molybdenum (niobium) / IGZO film layer of this embodiment includes the following components according to the mass percentage:

[0104]

[0105] The above-mentioned nitric acid and water were mixed and stirred, and then hydrofluoric acid, tetramethylammonium hydroxide, phenylurea, 3,9-diaminocarbazole and hydrogen peroxide were sequentially added to the mixed system and stirred. It can be used after being filtered by 0.5μm and 0.2μm filter elements in turn. The pH of the A agent was 3.1.

[0106] During the whole preparation process, the temperature of the etching solution A agent system was maintained below 45°C.

[0107] The etching solution B agent for the copper / molybdenum (niobium) / IGZO film layer of this embodiment includes the following components according to the mass percentage:

[0108]

[0109] The above-mentioned nitric acid and water were mixed and stirred, and then hydrofluoric acid, tetramethylammonium hydroxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com