Testing method of shearing property of waveform steel-web combination beam

A technology of corrugated steel webs and testing methods, applied in the field of bridge technology research, to achieve reliable research results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

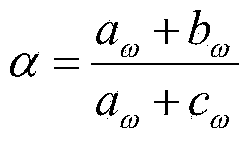

[0034] Please refer to figure 1 and figure 2 Shown, corrugated steel web concrete composite box girder is made up of different materials among the present invention, so when calculating the shear stiffness of this type of structure, can calculate according to the following method: the shear stiffness of upper and lower concrete slabs can be Negligible, this is because the shear stiffness of the concrete slab is smaller than that of the web corrugated steel plate, and the corrugated steel web is bent from the steel plate instead of the concrete web, so only the structural web can be considered in the calculation Shear stiffness, note that the shear stiffness of the corrugated steel plate is slightly smaller than that of the flat steel web. The following formula can be used for calculation:

[0035] GA=α·G x ·A w (2-3)

[0036] In the formula: A w — the cross-sectional area of the corrugated web;

[0037] G x — shear modulus of elasticity of the corrugated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com