Creep deformation test method and platform of full-dimension pipeline bend

A pipe elbow and creep test technology, applied in the research field of creep mechanical behavior of materials under large-scale complex stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

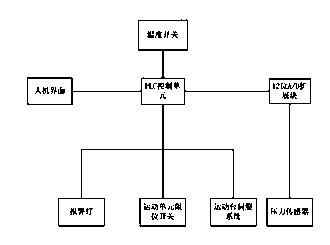

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

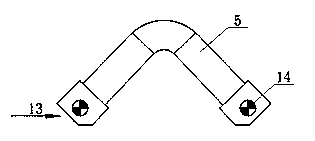

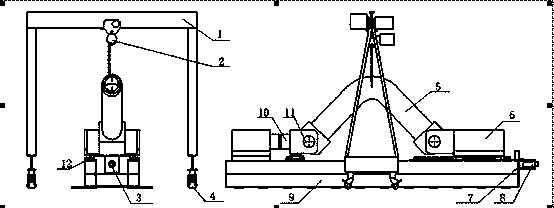

[0019] The method of using the full-scale pipeline elbow multi-axis creep experiment system in the present invention will be described below in conjunction with the implemented steps.

[0020] (1) Put the gantry frame (attached figure 1 Middle 1) Push it to an easy-to-operate place and lock the casters (attached figure 1 Medium 4);

[0021] (2) Use the manual lifting device on the gantry frame (attached figure 1 In 2) the sample (attached figure 1 5) Lift and place the sample in the working position;

[0022] (3) Put the sports platform (attached figure 1 Middle 6) Move to a position suitable for installing the sample;

[0023] (4) Pass the sample and connecting parts through the hinge pin (attached figure 1 Middle 11) The connection is firm, and the sample is separated from the manual lifting device;

[0024] (5) Loosen the casters of the gantry frame and move the gantry frame out of the working position;

[0025] (6) Install the parts required for heating and data co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com