Magnetic-control explosion-proof press button

A button and magnetron technology, applied in the field of circuit switching operation switch devices, can solve the problems of increased manufacturing cost, difficult contact spark hidden danger, difficult sealing, etc., and achieve the effect of eliminating influence and hidden danger of medium leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

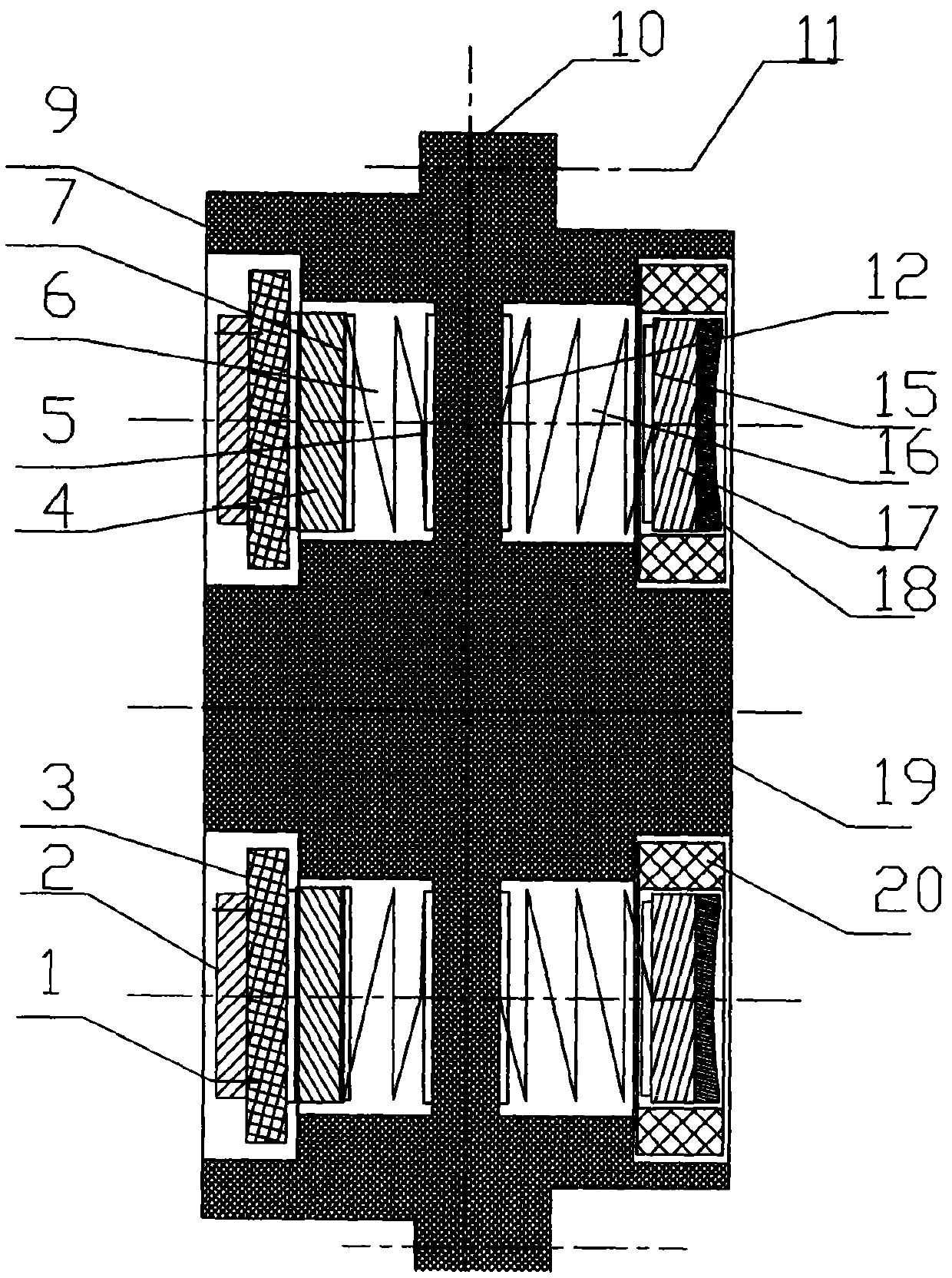

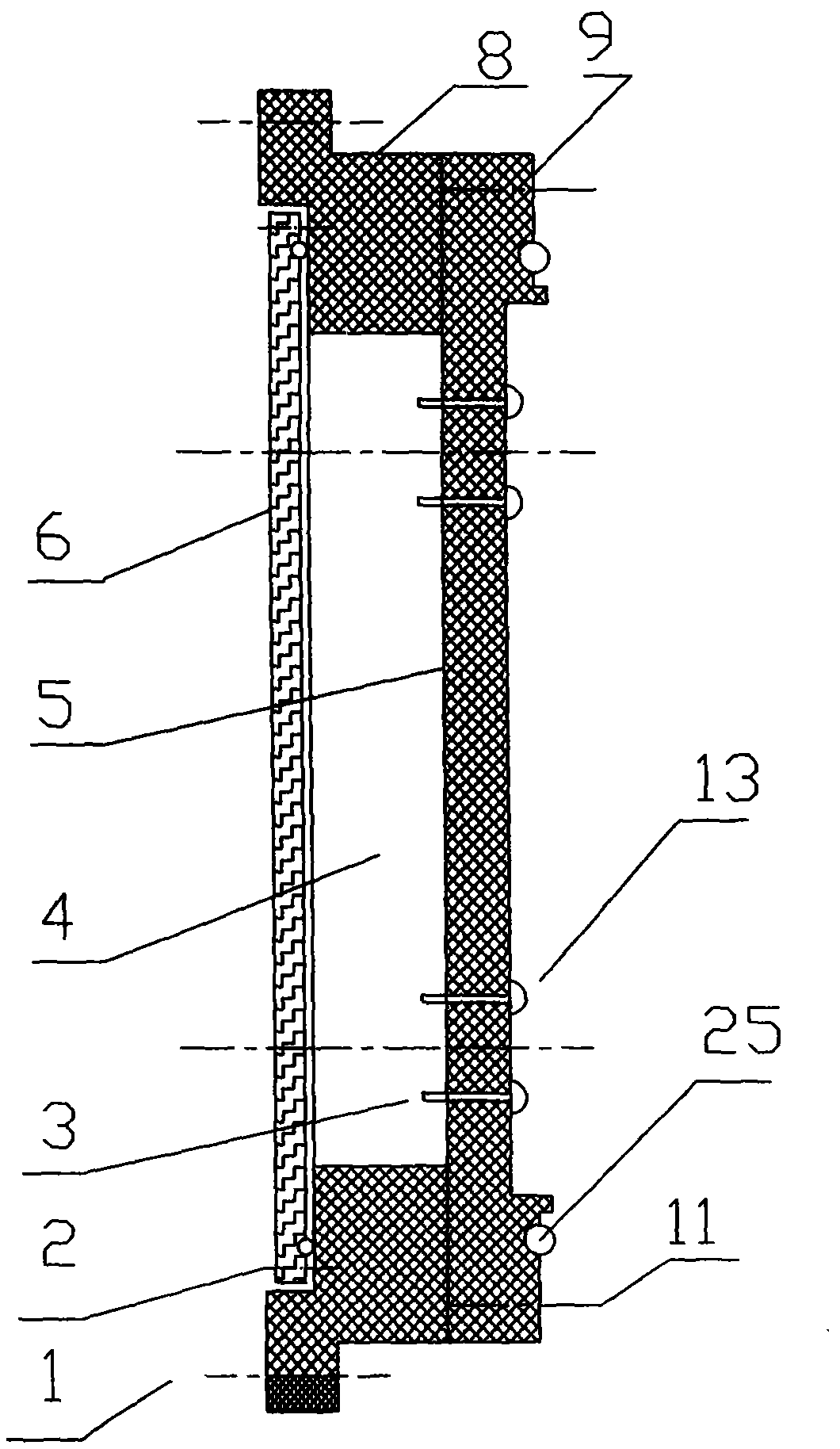

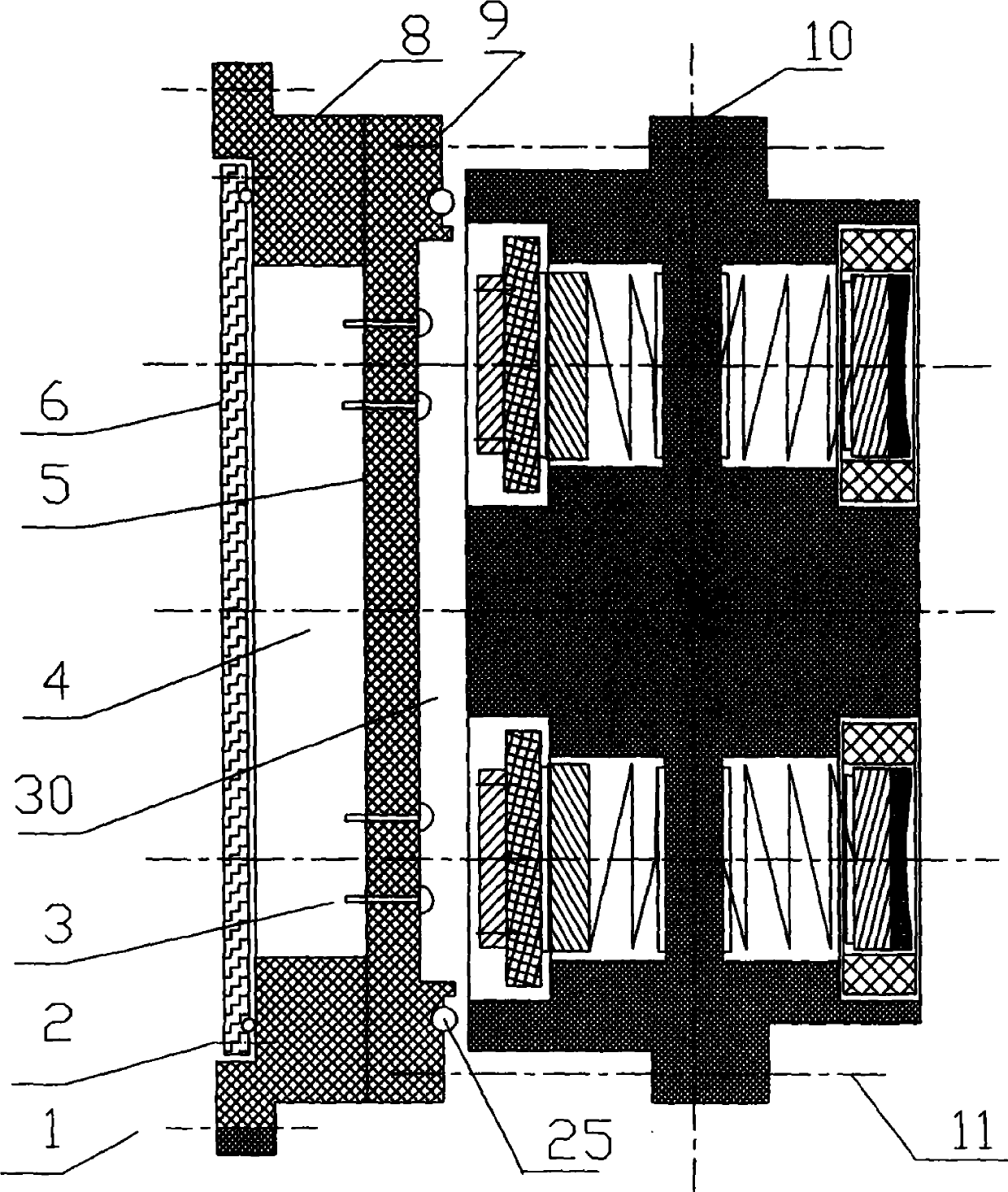

[0019] figure 1 A schematic structural diagram of the components of the magnetic drive isolation chamber of the present invention is shown; figure 2 It shows a schematic structural diagram of the static contact wiring compartment parts of the present invention; image 3 yes figure 1 and figure 2 Schematic diagram of the combined assembly structure of the two components.

[0020] refer to figure 1 1. A magnetically driven isolation chamber component of a magnetically controlled explosion-proof button of the present invention includes an assembly sealing end face 9 and an environmental contact surface 19, and one or more pairs of blind holes that are not connected to each other are arranged symmetrically within the space formed by the two planes, and each pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com