Spiral opener test bed of orchard ditcher

A screw-type opener technology, applied in the field of orchard trencher screw-type opener test bench, can solve the problems of difficult disassembly and assembly, low efficiency, high labor intensity, etc., and achieves strong repeatability, high efficiency, The effect of fewer experimenters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

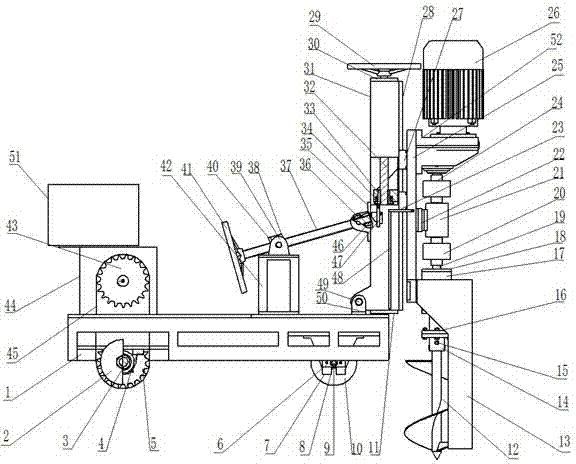

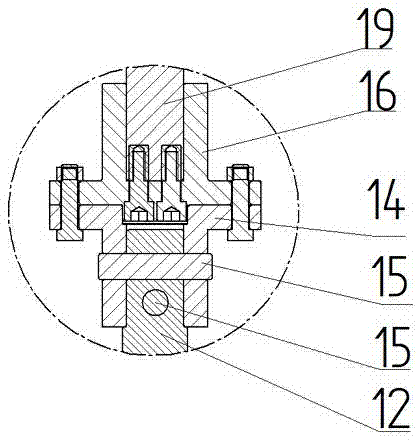

[0014] See figure 1 , orchard ditching machine spiral type ditcher test bench of the present invention comprises traveling mechanism, elevating mechanism, ditching angle adjustment mechanism and ditching mechanism; Said traveling mechanism is positioned at the bottom of experimental bench, realizes the walking of test bench; Said lifting The mechanism is located at the rear of the test bench and is connected to the running mechanism through a hinge; one end of the ditching angle adjustment mechanism is hinged to the lifting mechanism, and the other end is hinged to the upper end of the running mechanism; the ditching mechanism is located between the running mechanism and the ditching lifting mechanism. The rear end of the mechanism is firmly connected with the ditching lifting mechanism by screws.

[0015] The traveling mechanism includes a traveling base plate 1, a driving motor 51, a worm gear reducer 44, a driving sprocket 43, a chain 45, a driven sprocket 5, a driving shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com