Integrated manufacturing method of a novel composite ligament-bone scaffold

A technology of composite materials and bone scaffolds, applied in the direction of ligaments, scaffolds, prostheses, etc., can solve the problems of stress concentration, ligament graft damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

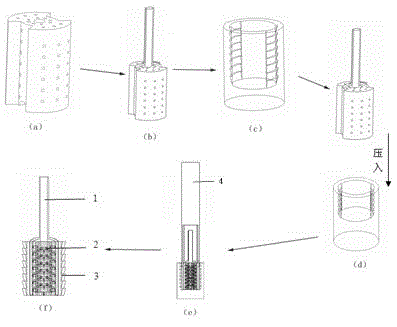

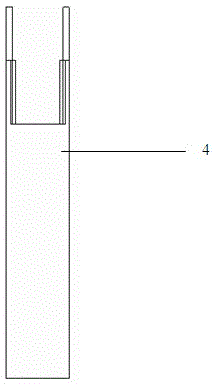

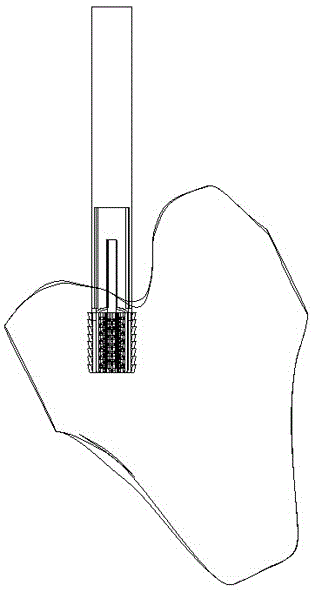

[0020] The process of the integrated manufacturing method of the new composite ligament-bone scaffold is as follows: figure 1 As shown, the negative model of the bone scaffold and the negative mold of the fixation nails are designed by computer, the negative mold of the bone scaffold is generated by Boolean operations, and the negative mold of the bone scaffold and the negative mold of the fixation nails are manufactured by rapid prototyping technology ( figure 1 Middle a).

[0021] Prepare ceramic slurry for the production of bone scaffold. The ceramic slurry is composed of ceramic material β-tricalcium phosphate powder, water solvent deionized water, organic monomer acrylamide, dispersant sodium polyacrylate, crosslinking agent N,N-di Methacrylamide, initiator ammonium persulfate and catalyst N,N,N,N-tetramethylethylenediamine are mixed according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com