Mechanical device for sanitary towel production

A technology of mechanical equipment and sanitary napkins, applied in sanitary napkins, absorbent pads, etc., can solve the problems of insufficient surface protection of the permeable layer, bacteria, and increased total number of bacterial colonies, so as to eliminate the increase in the number of bacteria, facilitate equipment transformation, and eliminate possible sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

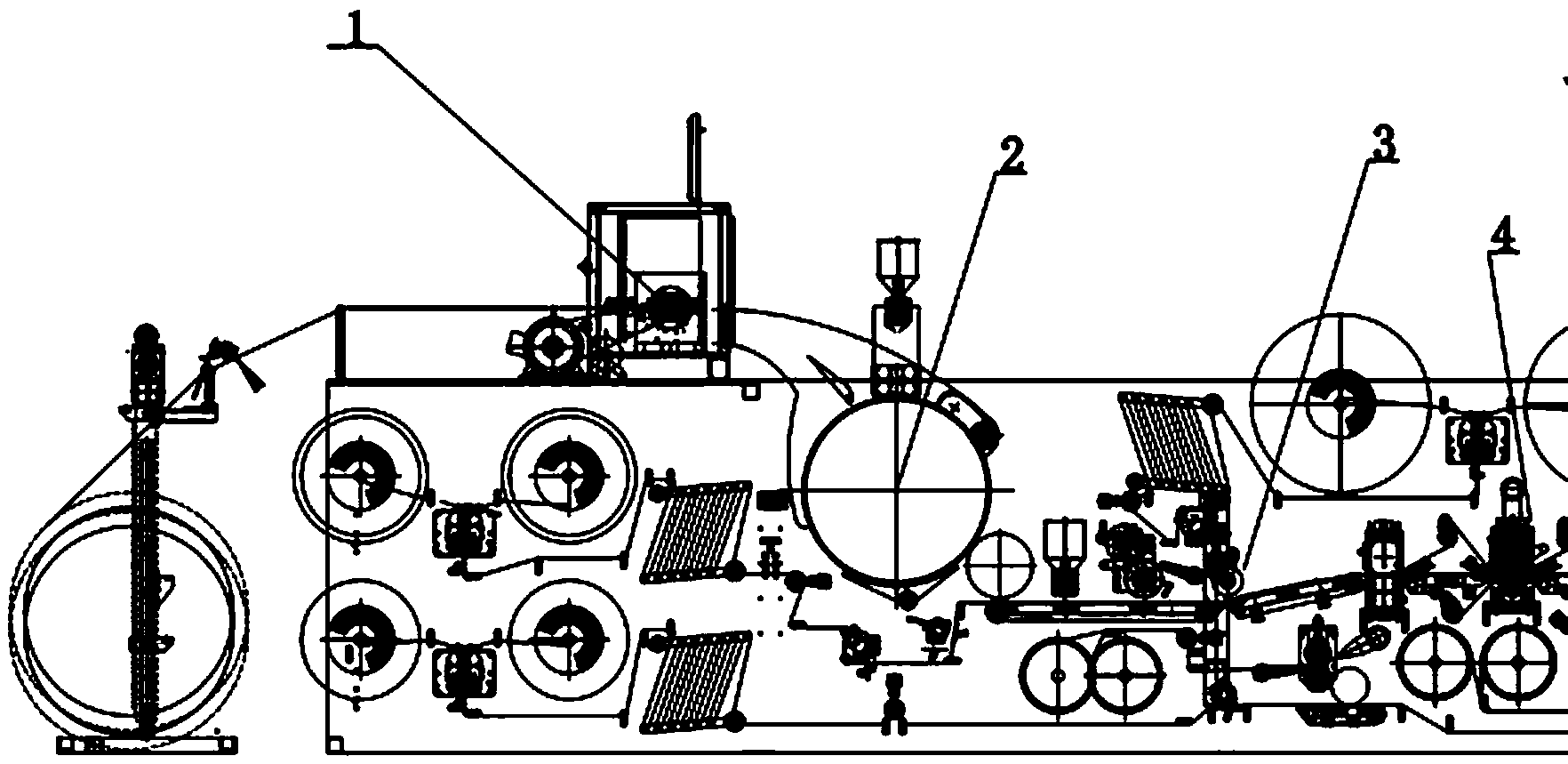

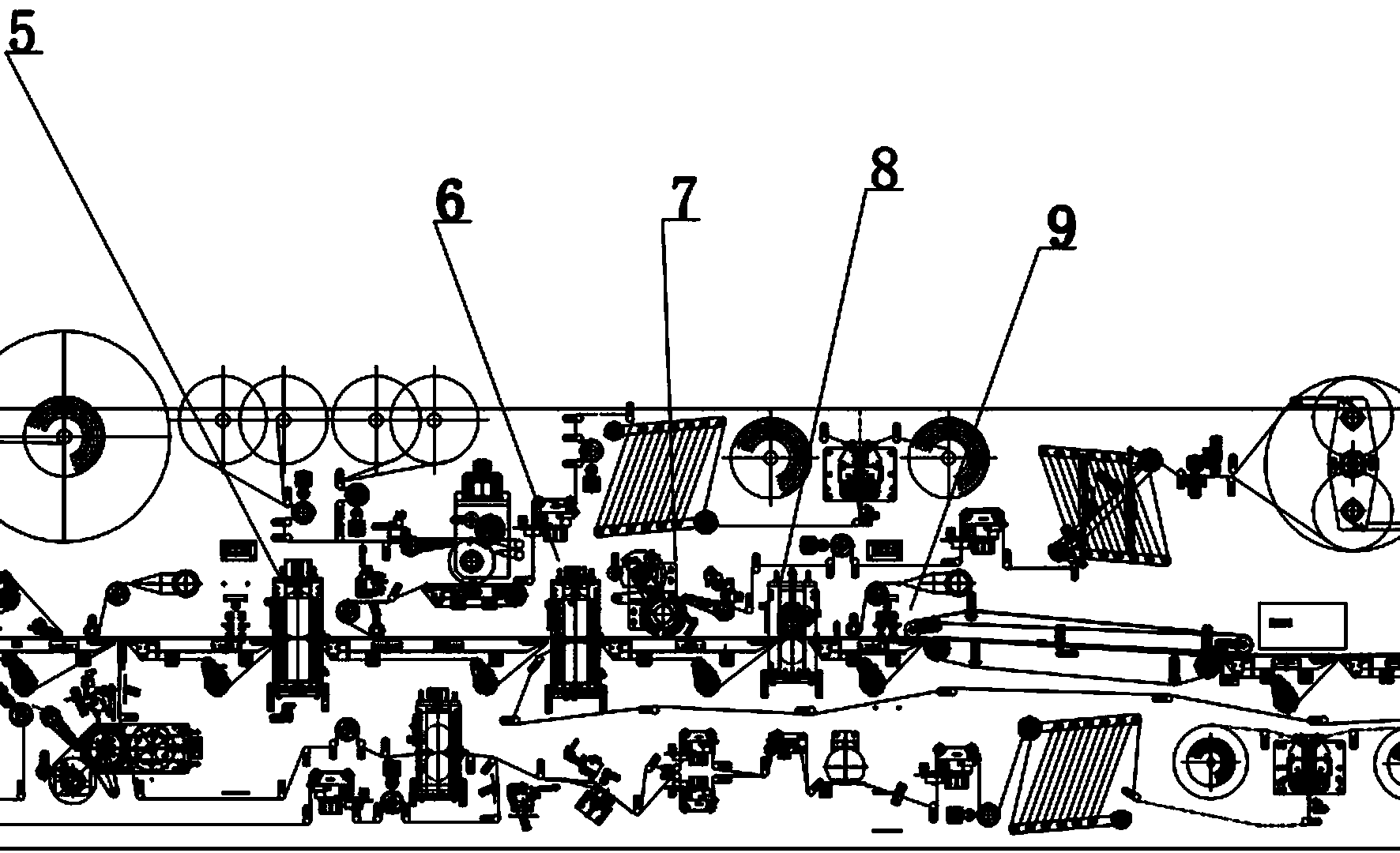

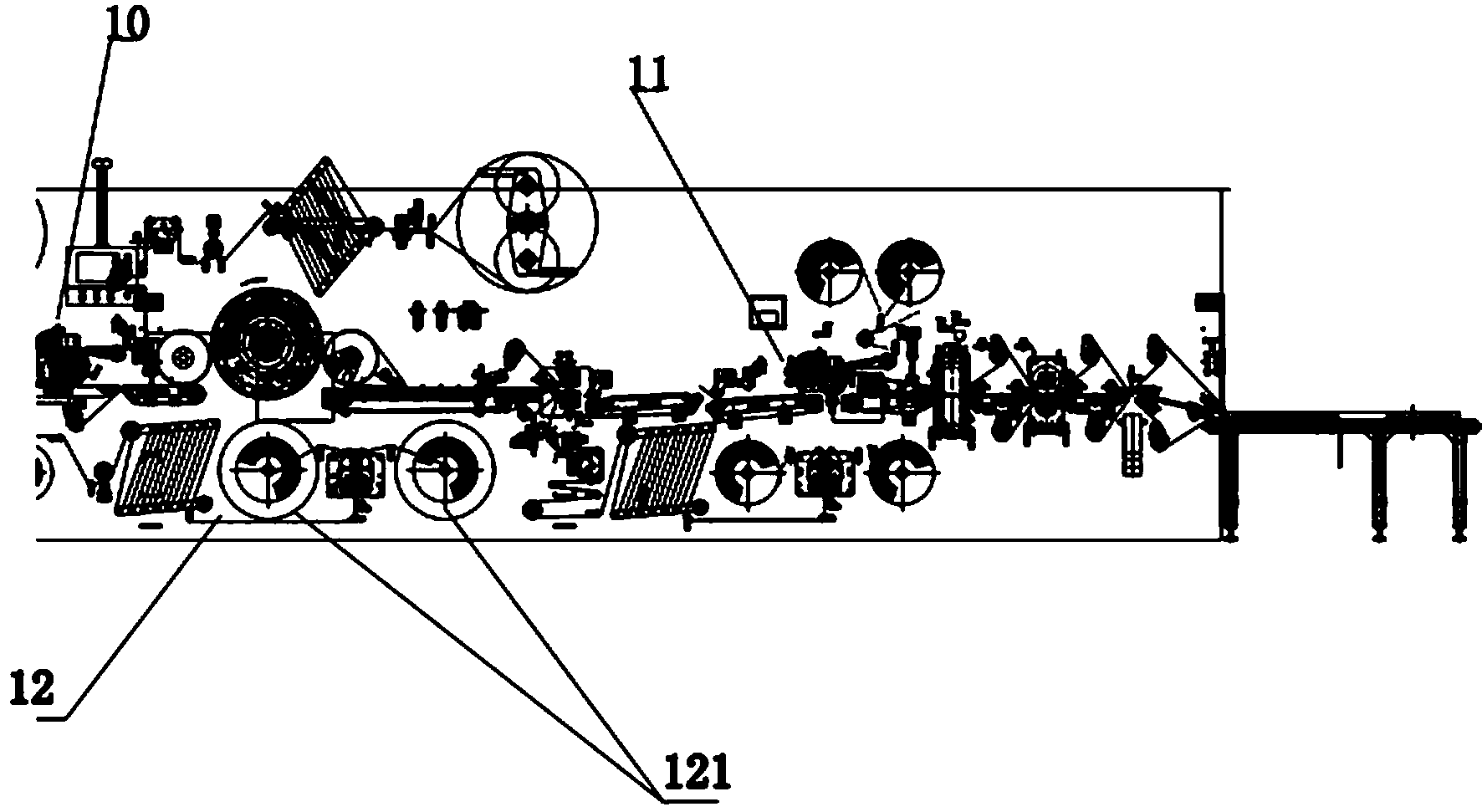

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] see Figure 1-3 , the mechanical equipment used in the production of sanitary napkins in this embodiment includes:

[0027] Pulp pulverizing device 1, which is used to pulverize pulp raw materials;

[0028] Cotton core forming device 2, which is used to form the pulverized pulp raw material into a cotton core for sanitary napkins;

[0029] Toilet paper / dust-free paper wrapping device 3, which is used to wrap the cotton core of the above-mentioned sanitary napkin with toilet paper or dust-free paper;

[0030] Cotton core cutting device 4, which is used to cut the wrapped cotton core;

[0031] Coating cotton core device 5, this device is used for coating the cotton core after slitting, covers non-woven fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com