Cyclone-type crushing device

A crushing device and cyclone technology, applied in the field of cyclone crushing devices, can solve the problems of low labor productivity, unfavorable large-scale production, non-uniform semi-finished products, etc., and achieve high labor productivity, conducive to large-scale production, and small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

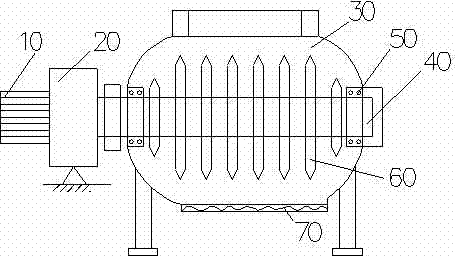

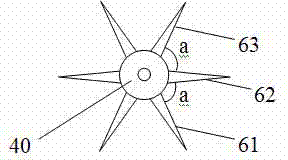

[0017] like figure 2 As shown, the cyclone crushing device of the present invention mainly collides the sheet-shaped thermosetting plastic semi-finished products (hereinafter referred to as semi-finished products) through a plurality of blades 60 provided on a rotating main shaft 40 to realize the crushing of the semi-finished products.

[0018] Specifically, a plurality of blades 60 are sequentially arranged on the main shaft 40, and the main shaft 40 provided with a plurality of blades 60 is horizontally penetrated into a casing 30, and the main shaft 40 passes through the end of the main shaft 40. The provided bearing 50 is connected with the casing 30 .

[0019] The rotation control mechanism of the main shaft 40 includes a motor 10 and a reducer 20 connected to the motor 10 , and the reducer 20 is connected to one end of the main shaft 40 through a coupling. The motor 10 provides a certain amount of power to drive the reducer 20 to run at a specified speed, drive the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com