Inlaid bearing inner wall blind hole lathe drilling power unit

A technology for power devices and blind holes, applied in boring/drilling devices, metal processing equipment, drilling/drilling equipment, etc., can solve problems such as unrealizable, and achieve the effects of easy maintenance, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

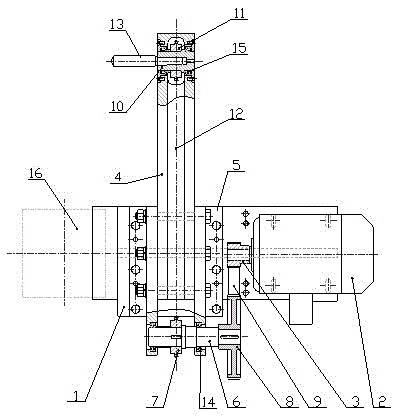

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

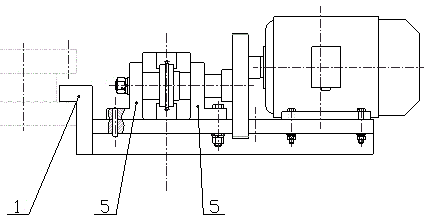

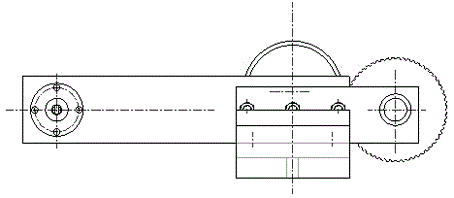

[0015] Such as Figure 1 to Figure 3 As shown, a power device for drilling a blind hole lathe with an inlaid bearing inner wall, including a bracket base 1, a motor 2, a small pulley 3, a knife plate 4, a fixed angle frame 5, a spindle 6, a sprocket 7, and a large pulley 8. Timing belt 9, Morse taper shaft 10, sprocket 11, chain 12, drilling tool 13, angular contact bearing 14, tapered roller bearing 15, lathe tool rest 16.

[0016] The bracket base 1 is installed on the lathe tool holder 16 and fixed by locking bolts. The motor 2 is installed on the bracket base 1. The small pulley 3 is connected to the output shaft of the motor 2. The large pulley 8 is connected to the small pulley 3 through the timing belt 9. Connection, the output shaft end of the mandrel 6 is connected with the large pulley 8, a pair of angular contact bearings 14 are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com