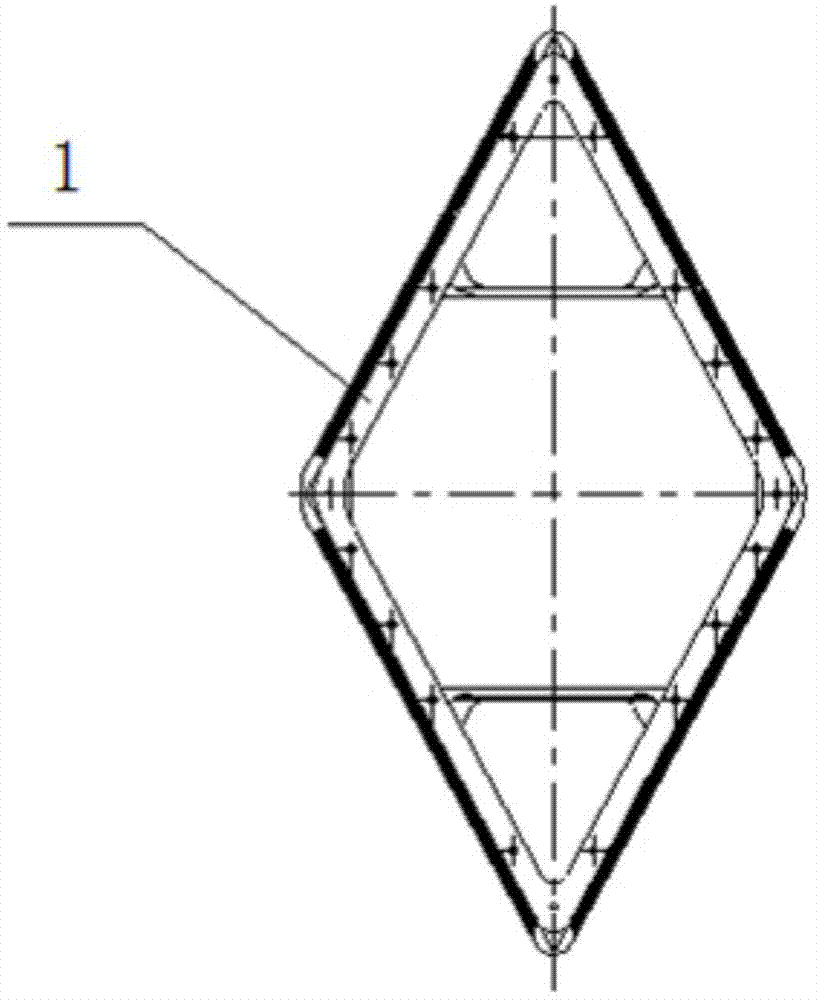

Machining method for large cast titanium alloy diamond-shaped cabin shell

A technology for casting titanium alloys and processing methods, which is used in aircraft parts, transportation and packaging, etc., can solve the problems of inability to comprehensively detect the size of castings, uneven machining allowances, and weak product rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

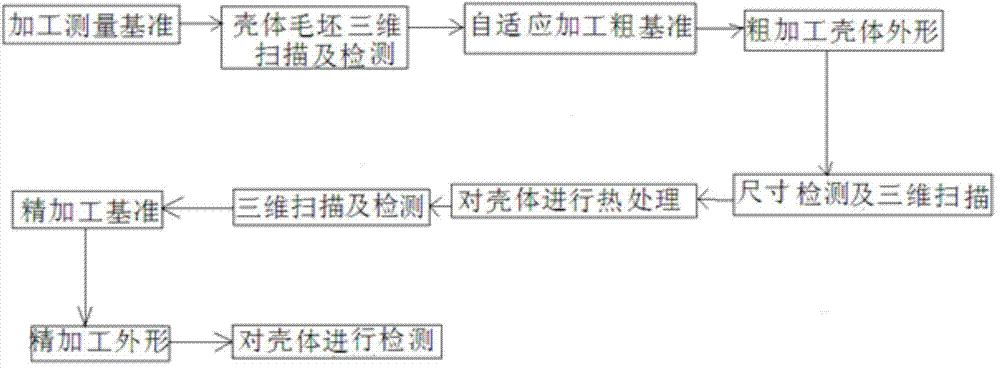

[0035] see figure 1 , a method for processing a large-scale cast titanium alloy diamond-shaped cabin shell provided by an embodiment of the present invention includes the following steps: Step 1, machining the measurement reference, leveling the rear end surface of the shell and processing it to see the light, and the light-seeing surface can reach 80%, Then align the outer four sides of the rhombus of the rear end frame, determine the center, and roughly process the four sides of the rhombus, so that each surface is exposed to 80% of the light. Step 2: Three-dimensional scanning and detection of the processed shell blank, determine the detection coordinate system according to the processed end face and the four sides of the rhombus, and use the internal shape of the shell as a reference to perform the best fitting between the shell casting model and the shell scanning model. Among them, three-dimensional scanning detects the quality of castings, and detects the internal and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com