Flexible Adaptive Mechanism of Angle Grinder

An angle grinder, self-adaptive technology, applied in the direction of machine tools, grinders, portable grinders, etc. suitable for grinding the edge of workpieces, it can solve the problem of affecting the grinding quality, inconsistent size and flash burrs, and the angle grinder is easy to damage, etc. problem, achieve the effect of improving work efficiency and reducing the difficulty of teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

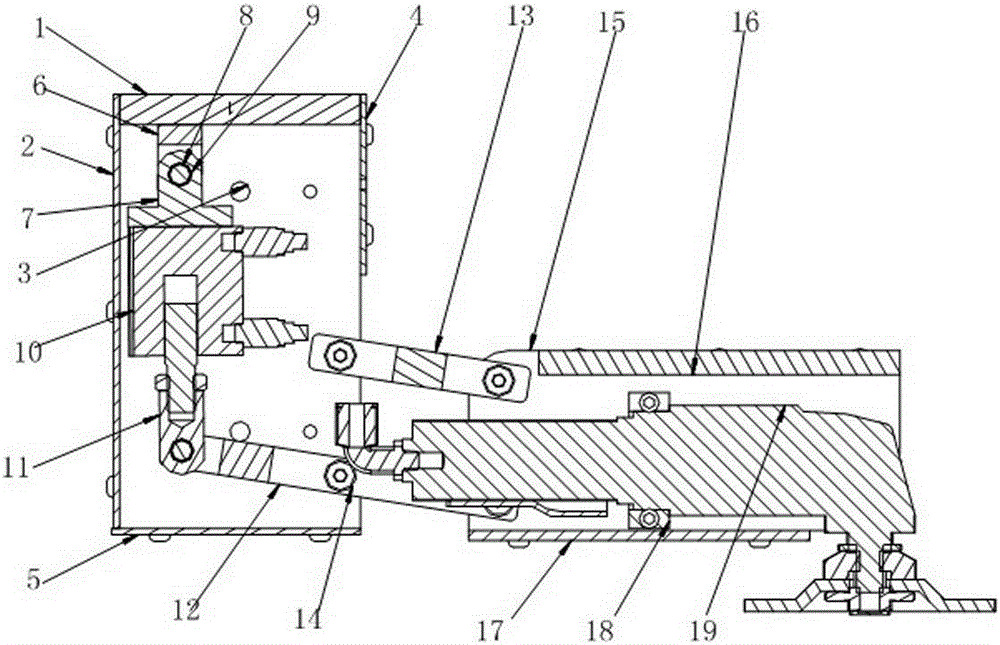

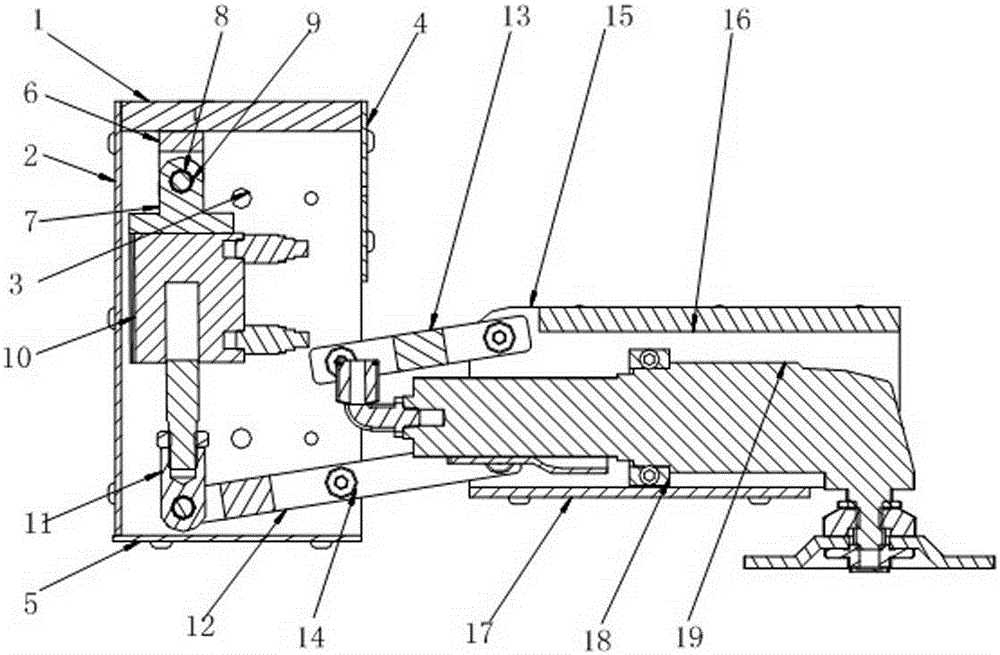

[0009] Such as figure 1 and figure 2 As shown, the flexible adaptive mechanism of the angle grinder of the present invention includes a first fixed plate 1, a first closed plate 2, a second fixed plate 3, a second closed plate 4, a third closed plate 5, a fixed block 6, and a mounting seat 7. Bushing 8, first equal-height bolt 9, cylinder 10, connector 11, first connecting frame 12, second connecting frame 13, second equal-height bolt 14, first support plate 15, second support plate 16 , the fourth sealing plate 17, the clamping block 18, the first fixing plate 1, the first sealing plate 2, the second sealing plate 4, and the third sealing plate 5 are sequentially connected to form a box body, and the fixing block 6 is located on the first fixing plate 1 Between the bushing 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com