Tooling for bonding split sealing ring and method applying tooling to bond sealing ring

A technology for bonding seals and sealing rings, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems that the two sections of the sealing ring are not completely aligned, affect the bonding strength of the sealing ring, and affect the sealing performance of the sealing ring, etc., to achieve Guaranteed sealing performance and bonding strength, uniform force, and the effect of ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

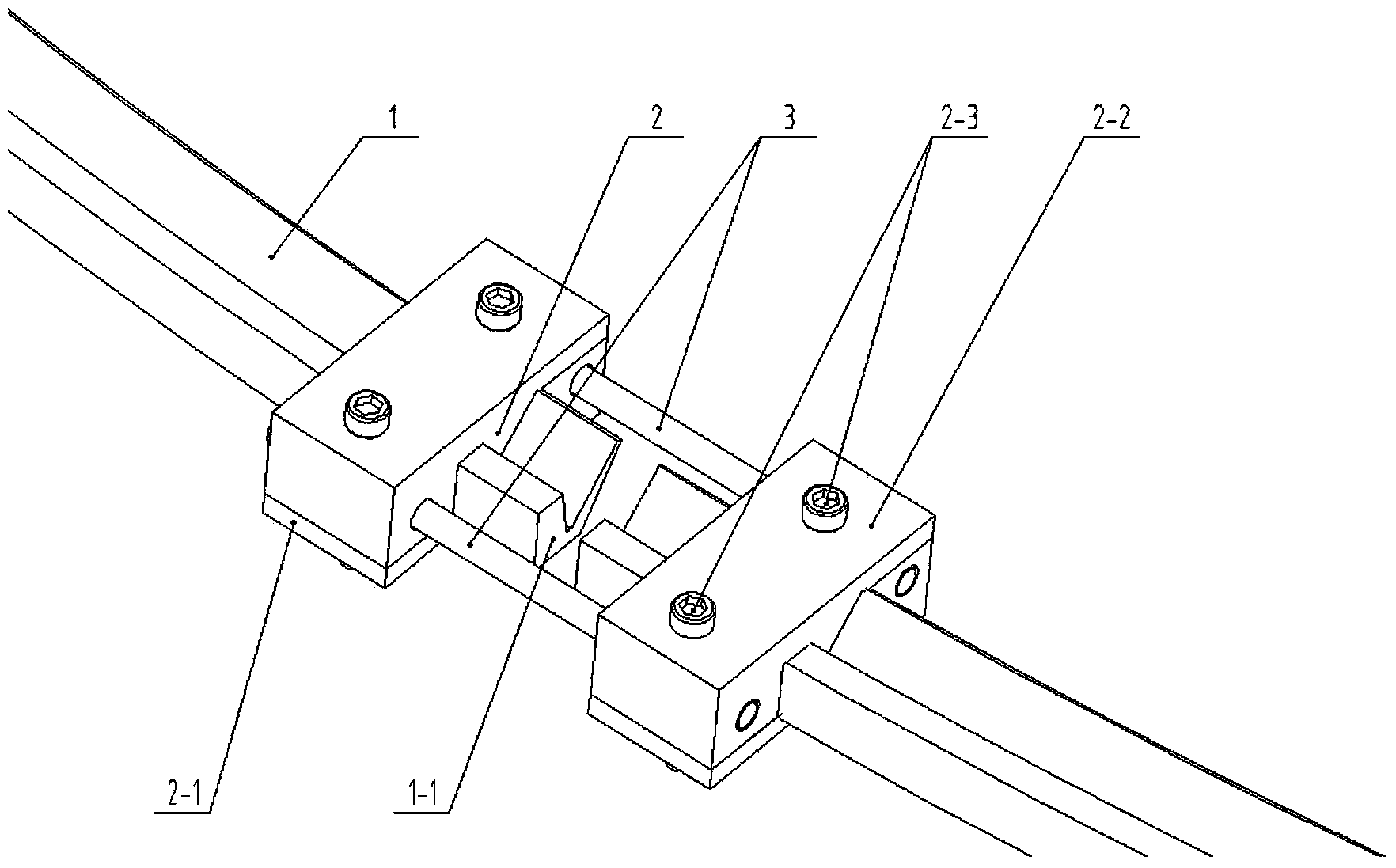

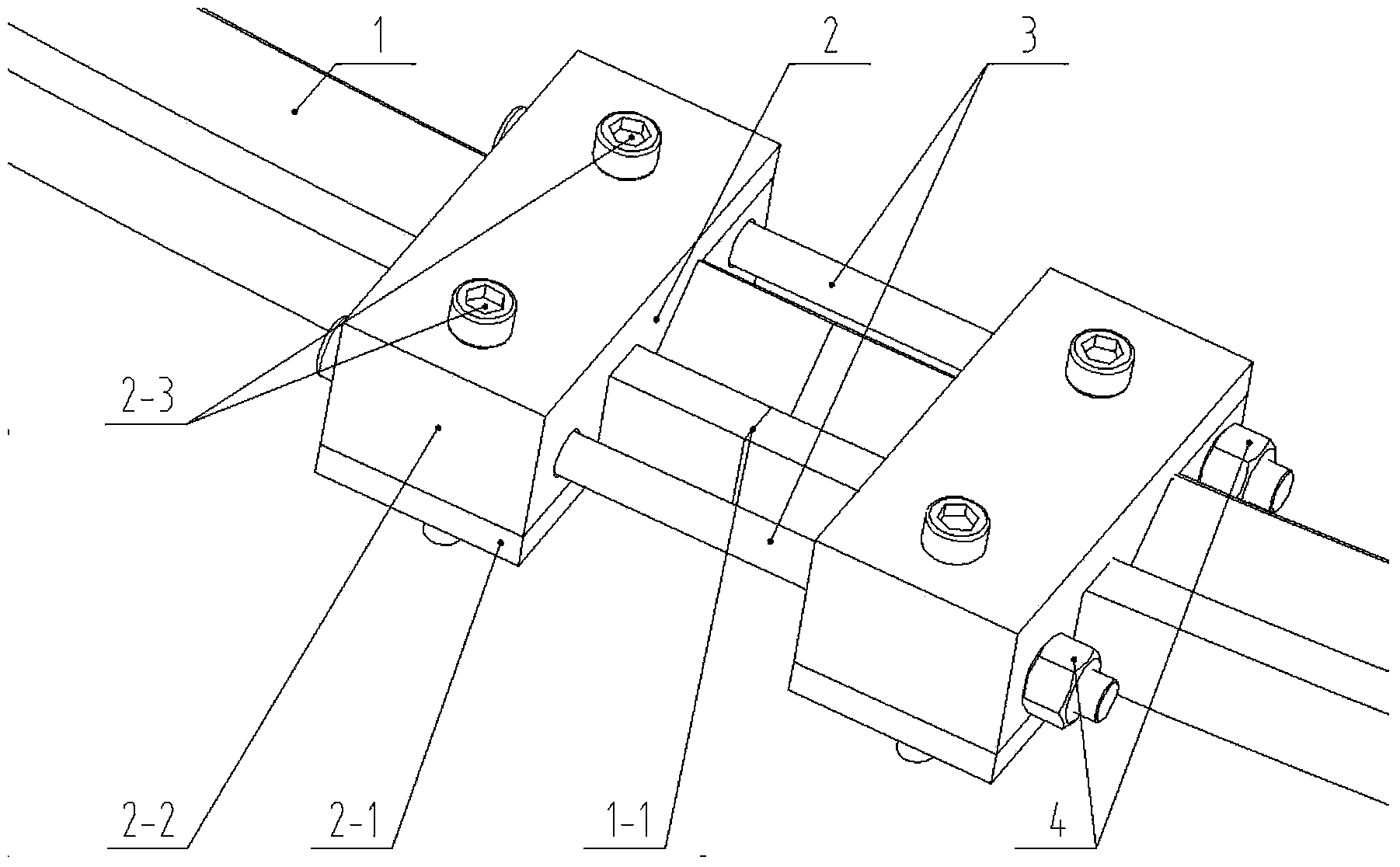

[0028] see figure 1 , 2 As shown, a tooling for bonding a split seal ring according to the present invention includes a pair of clamping blocks 2 for fixing the two ends of the split seal ring 1 respectively, and the pair of clamp blocks 2 pass through the guide rod 3 It is connected and can move toward each other along the axial direction of the guide rod 3, and there is no rotation between the clamp block 2 and the guide rod 3. In this way, the tooling for bonding the split sealing ring of the present invention has a guiding function, and the two bonding sections 1 - 1 of the split sealing ring 1 can be precisely aligned through the guide rod 3 . Here guide rod 3 can be as figure 1 , 2 The setting shown in is two, but it can also be set to a single.

[0029] Wherein, the clamping block 2 includes a clamping block upper body 2-2 and a clamping block lower body 2-1, and the clamping block upper body 2-2 and the clamping block lower body 2-1 are detachably connected, for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com