A solid tire dismounting and anti-tire structure

A solid tire and rim technology, applied in tire parts, rims, non-pneumatic tires, etc., can solve problems such as internal structure deformation, breaking, load-bearing frame and/or tire material damage, etc., to reduce installation weight, installation Easy to disassemble and versatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

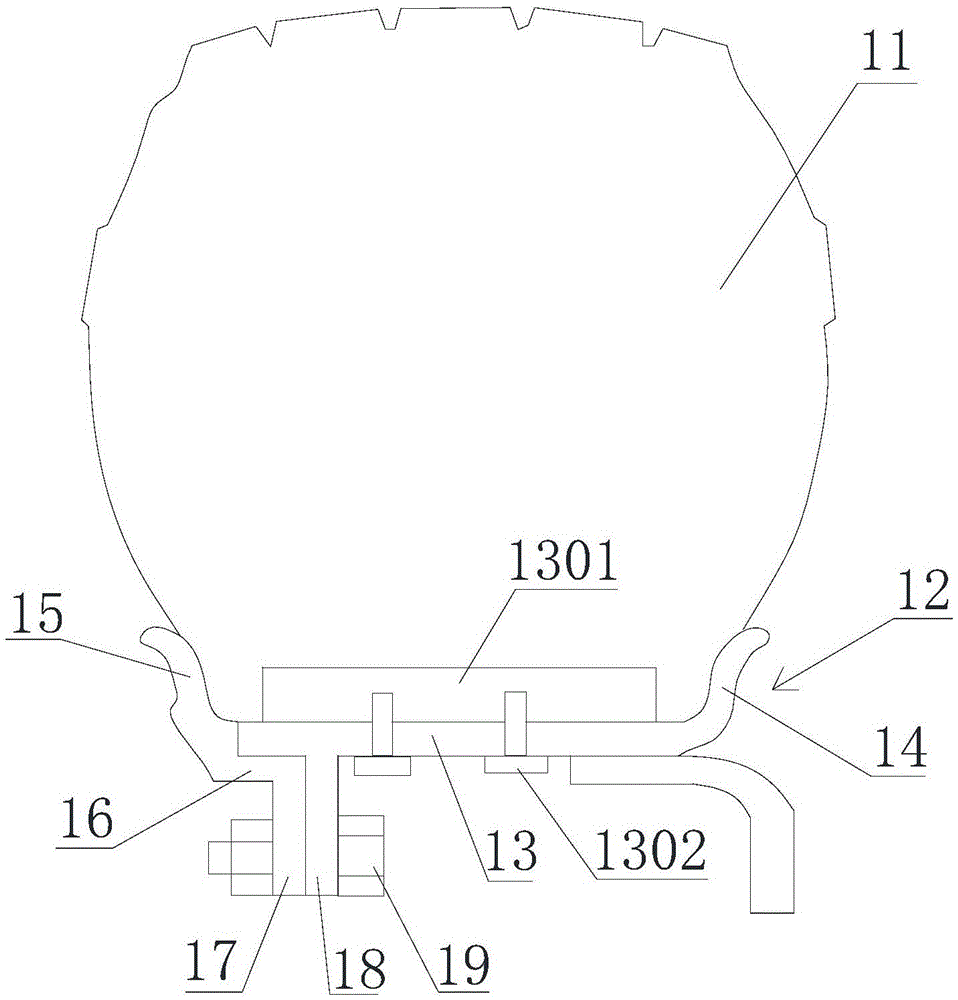

Embodiment 1

[0025] Such as figure 1 As shown, a solid tire assembly and detachment prevention structure includes a solid tire 11 and a rim 12, and the solid tire 11 is installed on the rim 12. The rim 12 includes a bead seat 13 , and rims are arranged on both sides of the bead seat 13 , one side is a fixed rim 14 and the other side is a detachable rim 15 . The fixed rim 14 is integrally connected with the bead seat 13, and the detachable rim 15 is connected with the bead seat 13 in a split type. The detachable rim 15 is connected to the rim extension ring 16, the detachable rim 15 is connected to the rim extension ring 16 in one piece, the rim extension ring 16 is connected to the extension ring flange 17, and the bead seat 13 is connected to the bead seat flange 18. The extension ring flange 17 is connected with the bead seat flange 18 through the anti-loosening bolt 19. Two stop blocks 1301 are symmetrically arranged on the bead seat 13 , and the stop blocks 1301 are fixed on the bead...

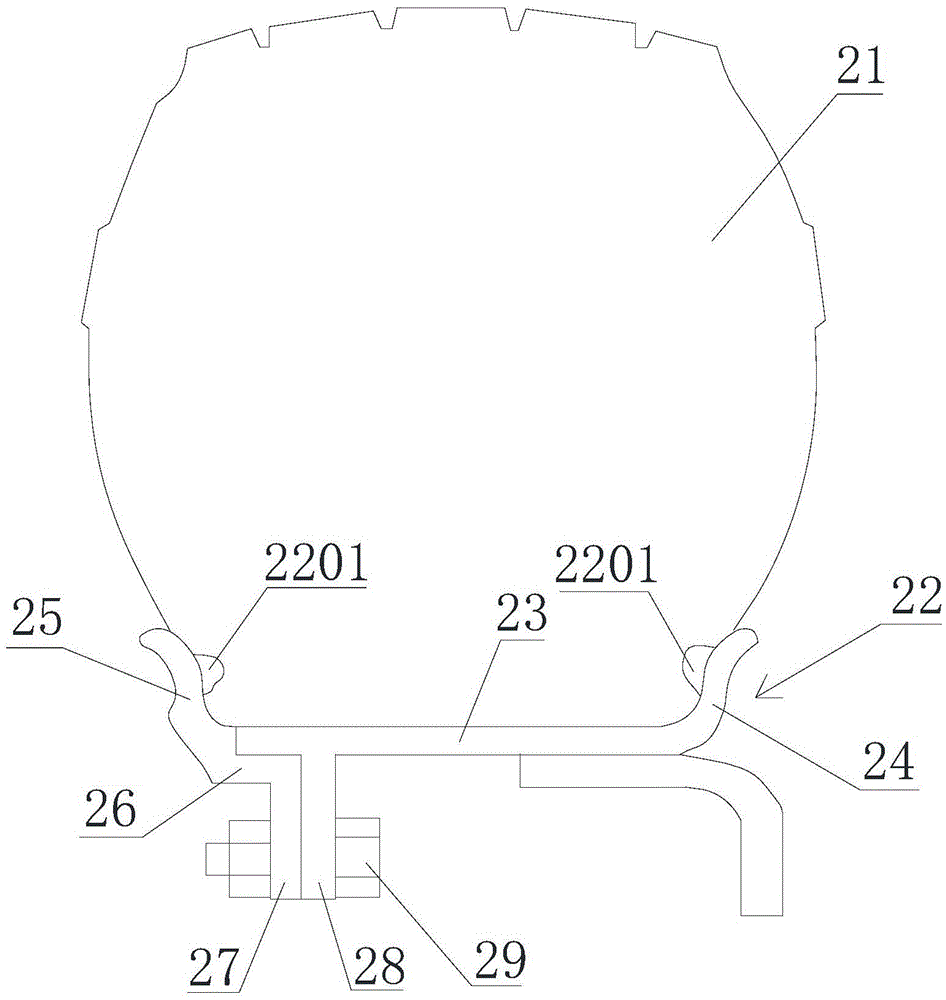

Embodiment 2

[0028] Such as figure 2 As shown, a solid tire dismounting and anti-tire structure includes a solid tire 21 and a rim 22, and the solid tire 21 is installed on the rim 22. The rim 22 includes a bead seat 23 , and rims are arranged on both sides of the bead seat 23 , one side is a fixed rim 24 and the other side is a detachable rim 25 . The fixed rim 24 is integrally connected with the bead seat 23 , and the detachable rim 25 is connected with the bead seat 23 in a split type. The detachable rim 25 is connected to the rim extension ring 26, and the detachable rim 25 is connected to the rim extension ring 26 in one piece, the rim extension ring 26 is connected to the extension ring flange 27, and the bead seat 23 is connected to the bead seat flange 28. The extension ring flange 27 is connected with the bead seat flange 28 through the anti-loosening bolt 29. Both the inner sides of the fixed rim 24 and the detachable rim 25 are provided with stop projections 2201, and the sto...

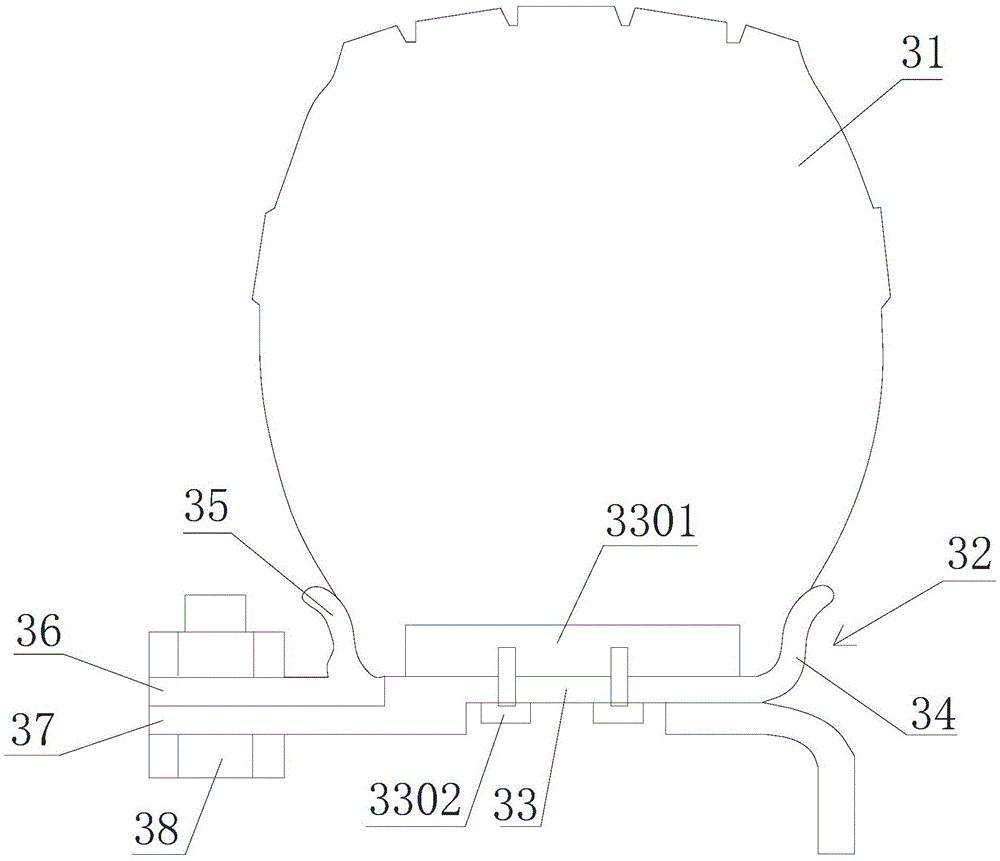

Embodiment 3

[0031] Such as image 3 As shown, a solid tire dismounting and anti-tire structure includes a solid tire 31 and a rim 32, and the solid tire 31 is installed on the rim 32. The rim 32 includes a bead seat 33 , and rims are arranged on both sides of the bead seat 33 , one side is a fixed rim 34 and the other side is a detachable rim 35 . The fixed rim 34 is integrally connected with the bead seat 33 , and the detachable rim 35 is connected with the bead seat 33 in a split type. The detachable rim 35 is connected to the rim extension ring 36, the bead seat 33 is connected to the bead seat extension ring 37, the bead seat extension ring 37 is arranged in parallel below the bead seat 33, and the bead seat extension ring 37 is connected to the bead seat Seats 33 are partially overlapped, and the two are connected in a stepped shape. The rim extension ring 36 is arranged closely above the bead seat extension ring 37 . The rim extension ring 36 is connected with the bead seat exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com