A corner transfer mechanism

A transmission mechanism and corner technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency, high maintenance costs, increased human resource costs, etc., and achieve the effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

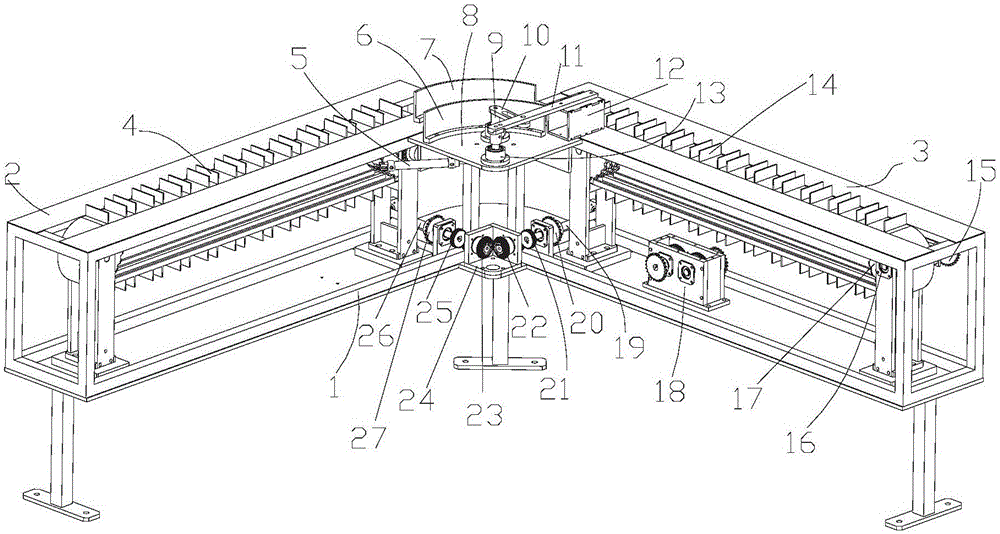

[0059] A corner transmission mechanism, including a control system (not shown), a frame 1, a motor 18, a first conveyor belt 14, a first drive device, a synchronization device, a second conveyor belt 4, a second drive device and a corner device;

[0060] Wherein, the control system is used to control the actions of the motor 18, the first conveyor belt 14, the synchronizing device, the second conveyor belt 4 and the corner device;

[0061] The frame 1 includes a first side 3, a second side 2, a first mounting plate 8 and a second mounting plate 24, the first side 3 and the second side 2 intersect, and the angle formed by them is adjustable; the second A mounting plate 8 and a second mounting plate 24 are located at the connecting portion of the first side 3 and the second side 2, the first mounting plate 8 is lower than the first conveyor belt 14 and the second conveyor belt 4, and the second mounting plate 24 is lower On the first mounting plate 8; the frame 1 is used to inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com