Mounting structure for plate material fixing element for laminating machine as well as top plate and laminating machine

一种安装结构、固定件的技术,应用在层压装置、化学仪器和方法、层压辅助操作等方向,能够解决产品合格率下降、制造成本增加、玻璃板过压等问题,达到降低生产成本、提高合格率、避免过压现象的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

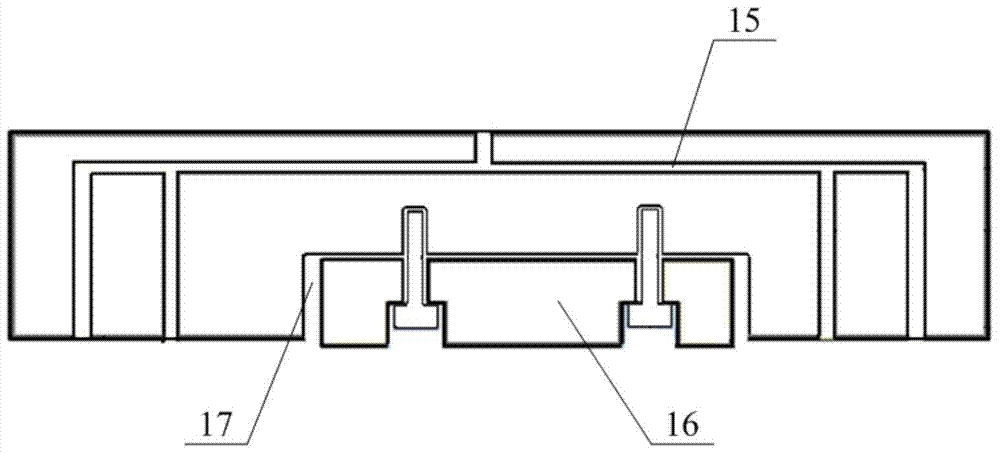

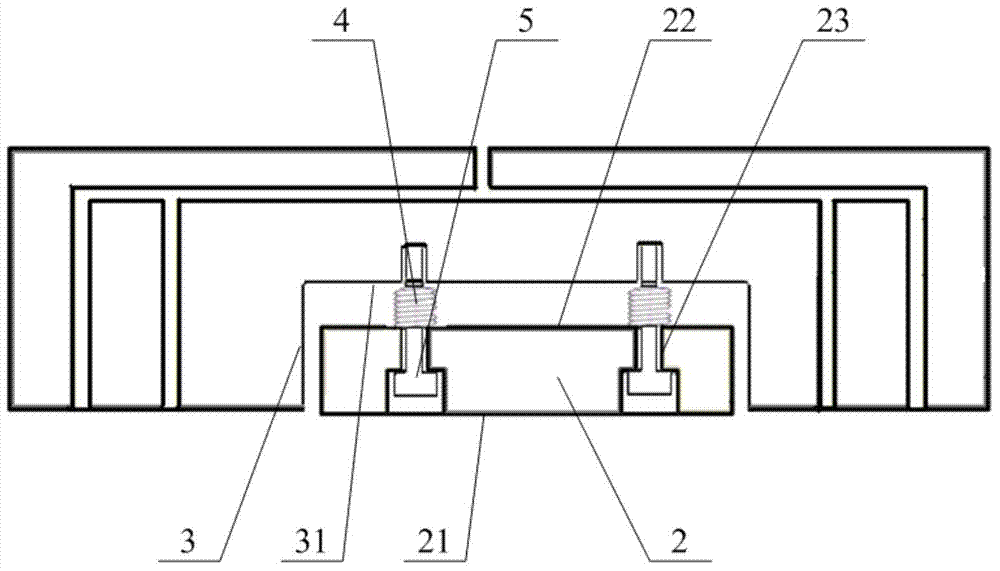

[0048] Such as image 3 with Figure 4 As shown, the installation structure of the plate fixing part 2 for the laminating machine provided in this embodiment includes a plate fixing part 2 and an installation groove 3 for installing the plate fixing part 2; the plate fixing part 2 is placed in the installation groove 3 and It can move vertically in the installation groove 3 , and an elastic reset member 4 is arranged between the plate fixing part 2 and the installation groove 3 .

[0049]Wherein, when the elastic restoring member 4 is stretched, the vertical first end portion 21 of the panel fixing member 2 extends to the vertical outer portion of the notch of the installation groove 3 .

[0050] When the first end portion 21 receives a pressure vertically toward the inside of the installation groove 3 , the plate fixing member 2 moves vertically toward the inside of the installation groove 3 and compresses the elastic reset member 4 .

[0051] In use, the elastic resetting ...

Embodiment 2

[0066] Such as Figure 5 with Image 6 As shown, the top plate for the laminating machine provided in this embodiment includes a plate body 6 and at least one installation structure of the plate fixing member 2 provided in the above-mentioned embodiment one provided on the plate body 6; wherein, the installation groove 3 Formed at the lower end portion of the plate body 6 in the vertical direction.

[0067] Further preferably, in order to ensure the stability of the connection between the upper glass plate and the top plate, a plurality of plate fixing parts 2 can be evenly distributed on the plate body 6. The installation structure can be referred to Figure 5 shown.

[0068] In this embodiment, when the upper glass plate is engaged with the plate fixing member 2 on the top plate, it can be lifted up by the mechanical arm. But further preferably, a vacuum suction port 61 may be formed at the vertical lower end of the plate body 6 , and a vacuum pipeline 62 communicating wi...

Embodiment 3

[0070] The laminating machine provided in this embodiment includes a bottom plate and a top plate for the laminating machine provided in the second embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com