Preparation method of epoxysuccinic acid catalyst

The technology of epoxy succinic acid and poly epoxy succinic acid is applied in the production field of scale inhibitor and dispersant poly epoxy succinic acid catalyst, which can solve the problems of easy loss, no fixed system for tungstate catalyst, high cost, and saves Effect of tungstate catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

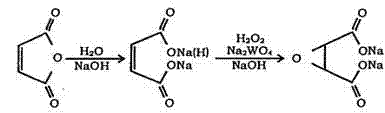

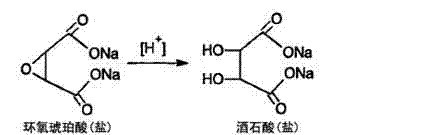

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, catalyst preparation embodiment:

[0034] 1. Resin pretreatment, choose D209, D296 or D301 styrene macroporous resin, dip and wash, soak with 1N sodium hydroxide solution, wash with water until neutral, soak with 1N hydrochloric acid solution, wash with water until neutral, and then Soak in 1N sodium hydroxide solution and wash with alkali, then wash with water until neutral to obtain a strongly basic anion exchange resin with a pH of 8-10;

[0035] 2. WO 4 2 Adsorption: 1) Pack the strongly basic anion exchange resin with a pH of 8-10 obtained from the pretreatment into the column, wash it with 3-5 times of deionized water, and then wash it with 5% Na 2 WO 4 The solution flows through the resin bed from top to bottom at a flow rate of 0.5 times the bed volume per hour; when the pH value of the outlet reaches above 11, the OH in the resin - started to be WO 4 2- 2) continue to use 5% Na 2 WO 4 The solution flows through the resin bed from top to bo...

Embodiment 2

[0037] Embodiment 2, catalyst preparation embodiment

[0038] Resin pretreatment is identical with embodiment 1, but WO 4 2 The adsorption adopts soaking method, is that the strong basic anion exchange resin that the pH that pretreatment obtains is 8-10 uses weight content 5% Na 2 WO 4 Soak the solution for 1-2 hours, then rinse the resin with deionized water to remove free WO 4 2- , until no white turbidity appears in the effluent with 2% barium chloride solution; the resulting adsorbed WO 4 2- The macroporous resin was filtered to dryness under vacuum condition and used to produce polyepoxysuccinic acid, or stored for future use.

Embodiment 3

[0039] Embodiment 3, catalyst application embodiment:

[0040] 1) Oxidation reaction, add maleic anhydride in the reactor, add NaOH solution with a weight percentage of 50%, adjust the pH value to 8-8.5, and put the adsorbed WO 4 2- Macroporous resin, the amount of macroporous resin is 1-5% of the total weight, and 30% by weight of H 2 o 2 After the dropwise addition, the reaction continued for 0.5-1h. After the reaction, the reaction solution and the resin catalyst were collected; the maleic acid: the weight ratio of hydrogen peroxide was 1:1

[0041] 2) Polymerization reaction, adjust the pH of the reaction solution to 8 and the temperature at 70-95°C, add a composite initiator with a weight content of 5-10%, and polymerize for 1.5-3 hours to obtain polyepoxy amber with a scale inhibition rate greater than 95%. Acid products.

[0042] The resin catalyst after the oxidation reaction described above was re-exchanged with 1N NaOH, washed with alkali and acid, and adsorbed W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com