Glass heat insulation film and preparation method thereof

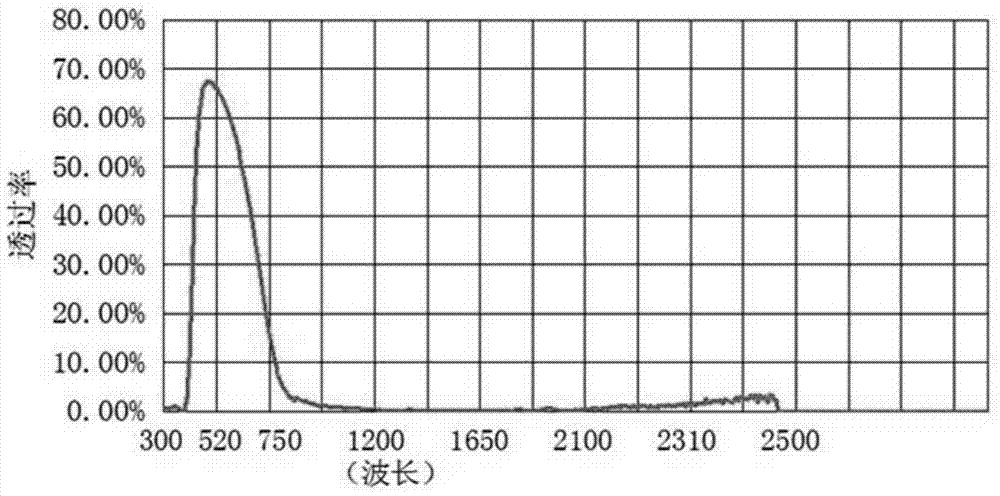

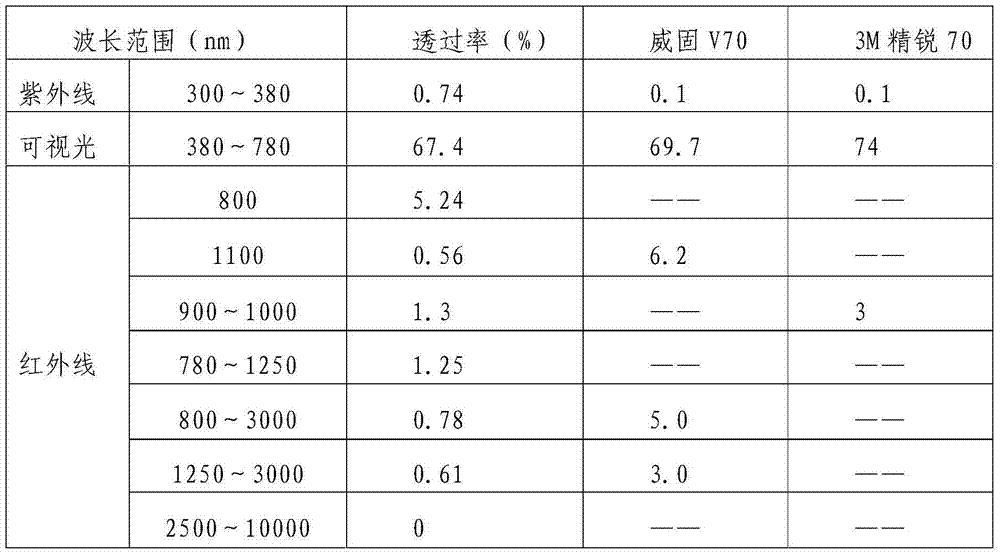

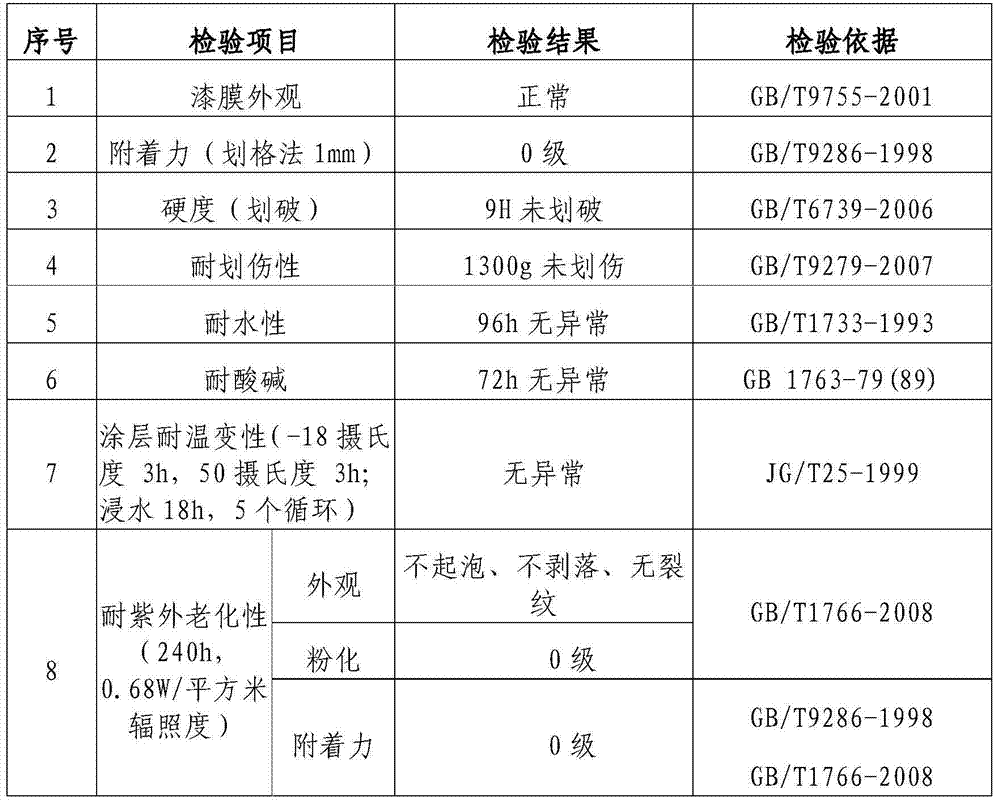

A glass heat insulation coating film, weight percentage technology, applied in the direction of coating, etc., can solve the problems of film erosion, poor aging resistance, shortened service life, etc., and achieve the effect of beautiful finished construction and good heat insulation, sunshade and heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment, the present invention is described in detail:

[0011] A glass heat insulation coating film, the composition of which comprises by weight percentage: 10-20% of acrylic resin, 6-9% of butyl acetate, 2-(2H-benzotriazol-2-yl)-4-methylphenol 6~9%, tin oxide 10~15%, antimony trioxide content less than 5%, dimethyl glutarate 10~15%, 2-butoxyethyl acetate 20~30%, 2-methoxy Ethanol 10 to 15%.

[0012] The glass heat-insulating coating film is made according to the following steps: S1: butyl acetate, 2-(2H-benzotriazol-2-yl)-4-methylphenol, oxidized Tin and antimony trioxide are added to the acrylic resin for full stirring and mixing, and then ground into a slurry;

[0013] S2: Add dimethyl glutarate, 2-butoxyethyl acetate and 2-methoxyethanol with high-speed stirring to disperse evenly.

[0014] When in use, it is only necessary to smear the glass heat insulating coating film of the present invention on the glass surface by means of roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com