An ecological wood foam extrusion die with a return-shaped core

An extrusion mold and ecological wood technology, which is applied in the field of ecological wood foaming extrusion molds, can solve the problems of poor product compactness, poor secondary processing performance, invisible annual ring wood grain and other problems, and achieve product compactness High, good secondary processing performance, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

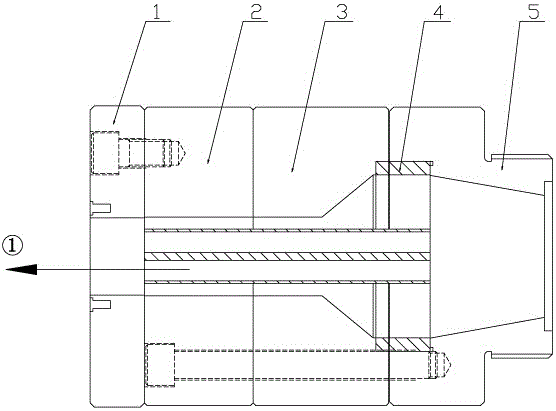

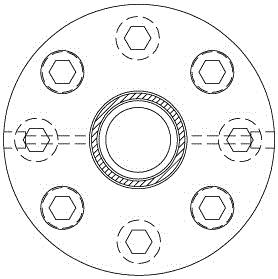

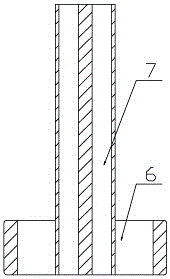

[0013] see figure 1 , figure 2 , the present invention is a kind of eco-wood foaming extrusion die with back-shaped core, including water jacket 1, die I2, die II3, die body 5 and mandrel 4, wherein water jacket, die I, die The die II and the die body are fixedly connected together in turn, and the mandrel is clamped in the die body, die I and die II. It is composed of the channel 8 of the outer ring. The channel of the outer ring is set on the channel of the inner ring. A plurality of large distribution holes 6 are evenly distributed in the outer ring channel, and a plurality of small distribution holes 7 are evenly distributed in the inner ring channel, and each large distribution hole and the small distribution hole are independent of each other.

[0014] In this embodiment, the section of the return-shaped mandrel can be set to two types: circular or square, wherein the section of the return-shaped mandrel is circular, see image 3 and Figure 4 , the section of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com