A control system for a circular knitting machine

A technology of circular weft knitting machine and control system, applied in knitting, weft knitting, textile and paper making, etc., can solve the problems of slow data transmission, low knitting speed, inconvenient interface operation, etc., to meet the timing requirements, improve real-time Sex, the effect of resolving temporal contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

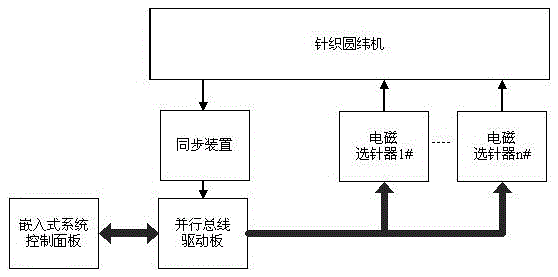

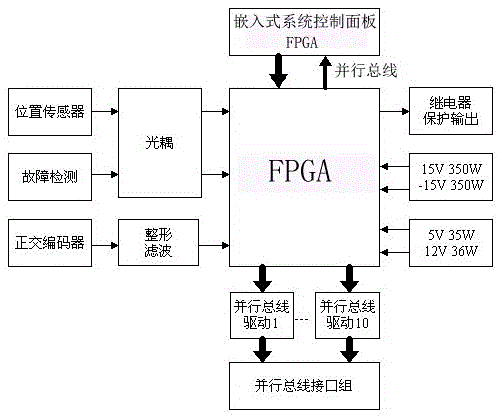

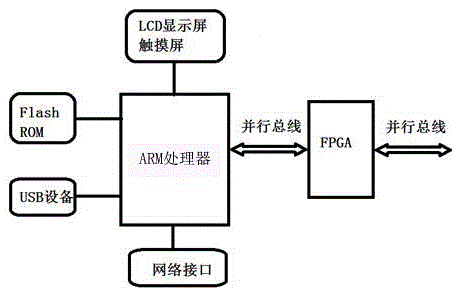

[0016] See Figure 1 to Figure 4 , The circular knitting machine control system includes an embedded system control panel, a parallel bus driver board, an electromagnetic needle selector unit, and the like. The embedded system control panel can realize the functions of pattern file reading and writing, control data analysis and organization, parameter setting, interface operation, etc.; the parallel bus driver board completes the signal preprocessing of the current running position of the circular knitting machine, control data forwarding, fault detection, emergency Stop control, etc.; the synchronization device is composed of a coupling, an encoder, and a zero position sensor. The coupling realizes the synchronization between the circular knitting machine gear and the encoder, and the needle positioning is realized through the A, B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com